Design of Pierce-Arrow Archer Hood Ornament

Back in 1926, Mr. Alvar K. Ternstedt, had the foresight to recognize, that if Ternstedt Manufacturing was to exist, and expand, in the Automotive Trim and Hardware field, a Styling Section was a requirement. His first preparation was to obtain the proper individual to man this department. Mr. Ternstedt proceeded to visit many Jewelry and Silverware Manufacturers located in the United States. Through his canvassing, he obtained information of a young man who had all the qualifications that he was looking for. This man was William N. Schnell, who, at the time, was working in Germany. He had the experience and background, in the field of deign and tooling, as well as being a skilled die sinker.

Mr. Schnell was contacted and accepted the position to become director of The Art and Color Department of Ternstedt.

Consequently, Mr. Schnell created a very unique department; consisting of artists, designers, clay modelers, chasers, tool men as well as foundry personnel. Within a short period of time, Mr. Schnell had an organization consisting of The Art and Color Department, Foundry and Tool Room. With this departmental structure his department could operate from a designer’s sketch, on to clay and make castings that could be finished by the die sinkers in the tool room. This group had the capabilities to make a steel hob if duplicated dies were required for large production quantities. However, if it were for a small production run the die sinkers had the ability to cut out the object directly into a solid block of steel. Many of the personnel that worked in the tool room area had previously worked for Mr. Schnell in Germany.

In the Spring of 1930 the Thernstedt Division of General Motors Corporation was contacted by the Pierce-Arrow Motor Car Division to design a new radiator cap which was to be used to replace the current ornament that was of an awkward helmeted archer. This assignment was given to Mr. Schnell.

There were two persons in the Art and Color Department selected by Mr. Schnell to be responsible for the designing and development of the Pierce-Arrow Hood Ornament: 1) Bonnie Lemm, to do the design work and, 2) Frederick Guntinni to sculpture, in clay, the ornament that was selected.

There are a few points of interest I would like to review with you related to the talent involving the people responsible for the styling and modeling the Pierce-Arrow Hood Ornament.

Bonnie Lemm, born in Clyde, Ohio, studied art at the Toledo-Ohio Museum of Design. After completion of her studies she stayed on and taught design for 3 years. In 1929, she accepted a job as a designer with Ternstedt. Remember, this was 1930, and even way back then the women’s touch was beginning to become evident. Incidentally, she was the first woman designer employed in the General Motors Corporation. She retired in November, 1955. The influence of women designers in the design of automotive interiors and exteriors is very evident in the General Motors cars of today.

Mr. Frederick Guntinni, born in London, England, studied in various Art Academies, located in France and Italy. He was an established sculptor in New York State before going Ternstedt in 1928. Also, I might mention he had won many awards in sculpturing in Europe, as well as the United States.

To give you a complete story of how the now famous Archer Ornament evolved, I would like to share with you some of my experiences involved in creating the Pierce-Arrow Archer.

As a young man, I was very fortunate to have the opportunity to serve my apprenticeship, as a stylist, in the Art and Color Department of the Ternstedt Division of General Motors Corporation, which since merger, in 1969, with Fisher Body Division of General Motors Corporation.

Included in my chores was “to keep the floor are clean.” In other words, I was given a broom – and that broom lead me on to a very interesting assignment, in fact, if it was not for that broom, I would not have the pleasure of sharing this evening with you, to review the background history of, our Pierce-Arrow Archer mood Ornament.

Bonnie started her project, designing the Ornament with great enthusiasm. After all of her research was done at The Art Museum and Public Library relating to archers, Bonnie selection a piece of work done by Rodin, a French sculptor for guidance. She had decided to do a realistic sculpture, and to be as authentic as possible.

Mr. Schnell worked very close with Bonnie during the early design stage to make sure the design would be feasible from a manufacturing standpoint. Often he voice his comments, related to body structure or arm position, of the Archer holding the bow and arrow, and being the busy body I was, using my broom or leaning on it, to make sure I would not miss out on the remarks that were made by Mr. Schnell to Bonnie – Mr. Schnell, turned and looked at me, and said, “Albert, I want yo auto strip to the waist and pose for Bonnie!” I really didn’t take him seriously. The next day, when he made his entrance into the studio, he wasn’t very pleased to hear that I had not posed for Bonnie – so immediately I stripped to the waist – and with my broom, using it as a bow, and a yard stick for an arrow, things began to fall in place. To further aid Bonnie, I attended Archery Classes where I began to use a real bow and arrow. Then the pose became more realistic and natural.

After Bonnie’s sketches were completed and reviewed with Bill Schnell, a selection was made. One color rendering was made and shown to the Management of Pierce-Arrow Motor Car Company. The original submittal was accepted without modifications. Pierce-Arrow Management was very complimentary and told Ternstedt to proceed and make a clay model for final approval.

Mr. Schnell selected Mr. Frederick Guntinni to sculpt the Archer in clay. As the clay model was being made of me, Bill Schnell would recommend where the die parting lines should be, also establish core construction so that the finished product would be acceptable from an appearance standpoint. A plaster mold consisting of five pieces was made to allow us to obtain duplicates of the original model.

Wax replicas were made, painted gold and submitted to Pierce-Arrow Motors for final approval.

Knowing that the next morning, Mr. Schnell had made arrangements to drive to Buffalo, New York (location of the Pierce-Arrow Motor Car Company), I worked overtime to paint the samples. After they were painted I had placed them on the window sill, in our studio, which was located on the northwest side of the build. The following morning, much to my surprise, I found the Archers had a let down – the sun had softened the wax causing the Archers left arm to drop in a down position. The unexpected condition delayed the trip one day.

When Mr. Schnell submitted the model fo the Pierce-Arrow Archer Hood Ornament to tPierce-Arrow Motors’ management, Ternstedt was given full approval to proceed with tooling of the now famous Archer.

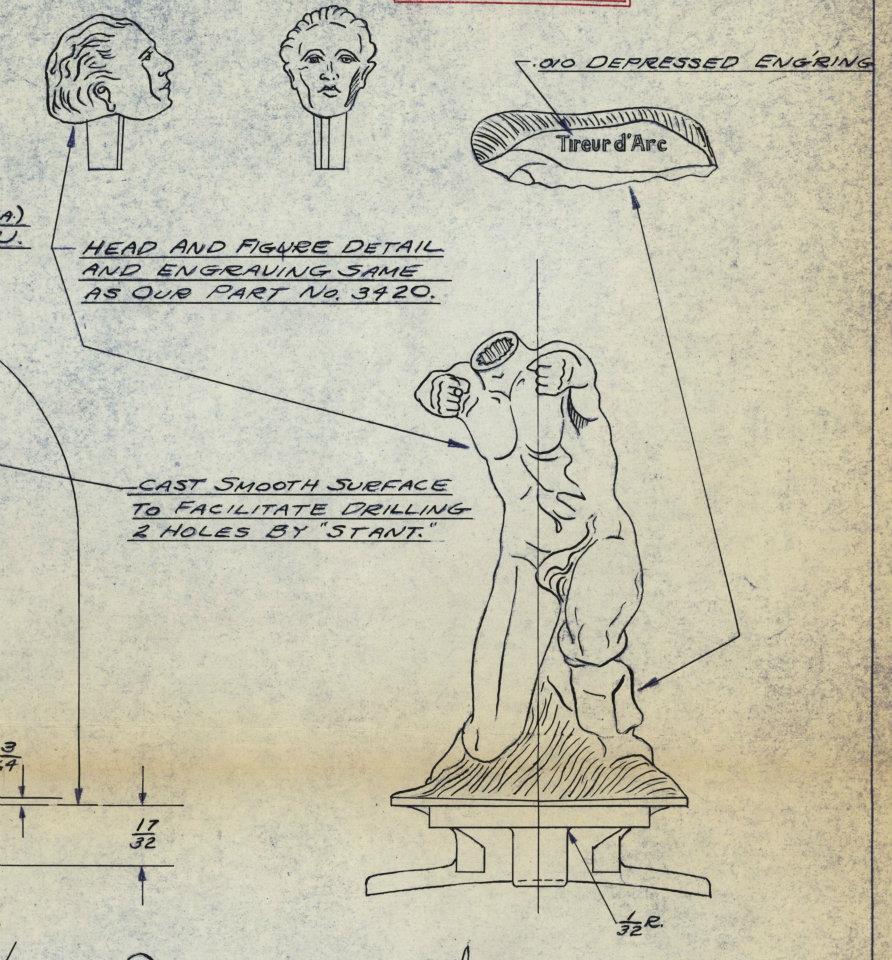

Here we see some copies of the actual production drawings used for this archer.

- The Body

- The Head

- Sub-Assembly

- The Bow

- The Arrow

The assembled Archer was truly a fine work of art.

The Archer was manufactured for a period of three years – from 1931 to 1933. In 1934 the archer was no longer produced by Ternstedt, but other companies manufactured copies of it. One of those companies was Doehler-Jarvis, which revised the model and produced a one piece part.

Incidentally, the Archer back in 1930 was also somewhat of a Cupid, because Bonnie Lemm, who designed the Archer, married Bill Walsh who was the foreman of the Tool Room, responsible for tooling the Archer Ornament.

So, Ladies and Gentlemen, from 1930 to 1975, the Archer still lives with me and I am happy to have this opportunity to tell about the development, design and manufacturing of the famous Pierce-Arrow Archer.

Thank you.

Source: The Chris & Kathleen Koch AACA Library & Research Center