- Home

- About Us

- Join/Renew

- Member Benefits

- Member Pages

- Log In

- Help

- Museum Store

Is there a source for the strip that is nailed through to stretch and seal the top? I don’t see anything in the parts directory or in the restoration supply catalog.

I don’t have anything of the original and don’t know the configuration. Thanks for any help.

Jim

Jim,

I got some from Restoration Supply in CA and it’s not a full half round it’s about half that but the profile is very close. The OE (I think) I took off was brass and the nails were soldered in place. The material from RS in aluminum, I haven’t gotten that far yet to install it. Jim L

Hi Jim and James. The original nails were sealed into the strip with a lead ‘BB’. A #6 or #8 shot. Then the BB was peened down, swelling it into the recess.

I don’t think the top material would survive having the strip heated hot enough to solder the hole shut.

I’ve drilled out the lead BB, and pushed the old nail out of nail-strips in the past.. a lot of work!

Greg Long

Thanks Jim and Greg, that explains it but more questions. I should look in the PASB’s I guess, but meanwhile…. Looking at Restoration Supply their catalog lists half round and shallower half ovals in various sizes in brass aluminum and steel. I assume one of these -brass or aluminum – is soft enough to bend to the tight radii in the corners (see picture).

Is the oval pre-drilled and countersunk to put the lead ball in before driving the nail? seems pretty tricky trying to drive a nail through a round ball!

Jim

I’m a bit slow, just realized that the nail is driven first and the ball is peened in on top of it. So I guess the drill – pun intended- is to drill the holes in the strip, drive the nails and punch them under the surface then pound the lead ball in on top? Do you do a countersink in the hole first?

Thanks, Jim

My memory tells me that one of you out there advised me that Model A Ford

strips would work.

There is a recess drilled for the nail’s head to be sunk into, and then the lead BB is put into the recess and then peened to fill the hole.

I have not bent new metal strips, I’ve only painstakingly repaired and straightened old strips and reused them.

Greg

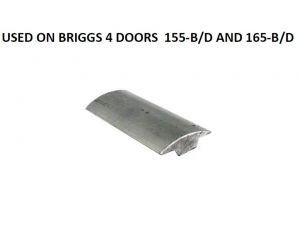

Tony, the Model A lead looks like a winner. Snyder’s Model A catalog shows several different strips that were used but I this one used on Briggs bodies looks like a good candidate. Snyder’s has instructions and pictures for installing this strip including pictures showing it bent to the tight radius curve.

can anyone say if the original P-A strips look like this cross-section?

Thanks, Jim