- Home

- About Us

- Join/Renew

- Member Benefits

- Member Pages

- Log In

- Help

- Museum Store

Home Page › Forums › Literature and Tools › Test

Test

Test

Hi Ryan, it was great to see you, your Dad and your wonderfully original ’32 at the Annual Meet in Lancaster/Hershey.

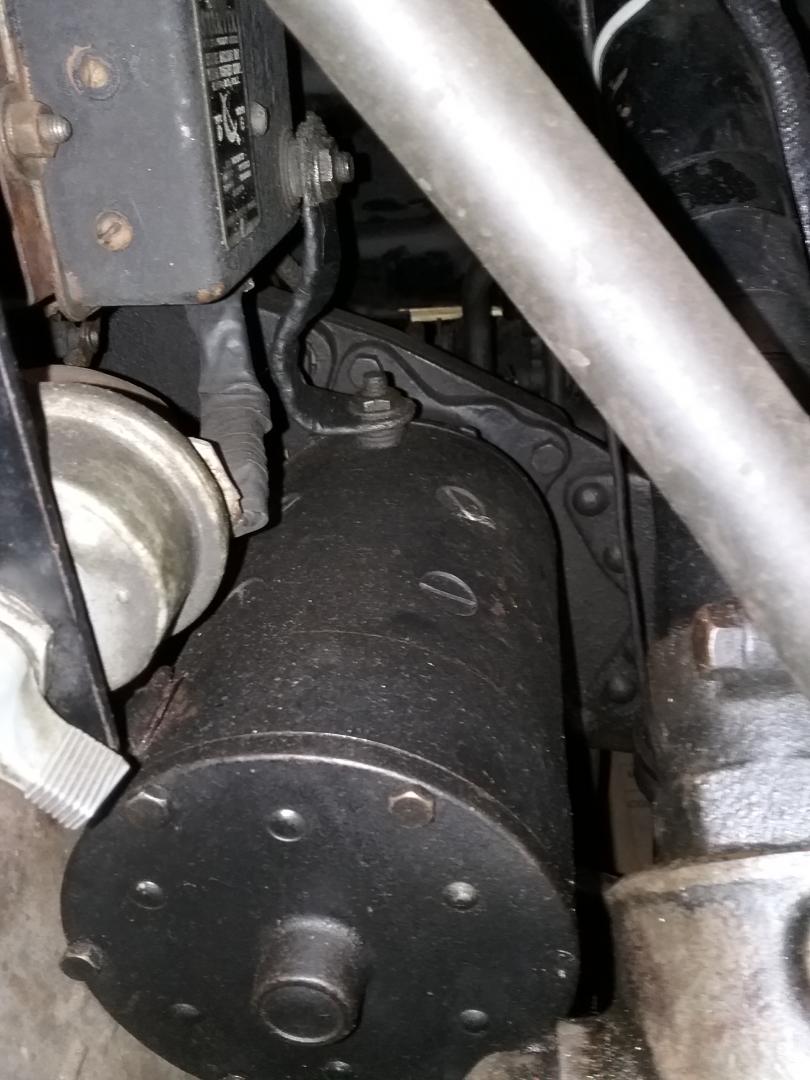

Regarding some of your photos above: On the Startix, the flat strap wire leads are unfortunately fairly high resistance and do slow down your cranking speed due to amperage draw and voltage drop. For your connection between your battery disconnect and the Startix, I’ll suggest making up a heavy copper welding cable with soldered on connectors. The ones I’ve made up have noticeably increased the cranking speed of the engine, and the ‘telling’ factor is that they don’t get warm or hot when cranking the engine.

The connection from the Startix to the stud on the side of the starter is easily seen, and a non-standard cable is noticeable. For that connection, I have found and used two of the flat strap cables. And since your’s are wrapped in tape, you could wrap two of them with tape and the double strap might not be as noticeable.

I think you already have a dedicated heavy cable from the + [pos] battery post to a bolt holding the starter to the engine. This too is critical to provide the needed amperage to the starter. The original flat-strap cable from the battery to the chassis just doesn’t carry enough current and gets HOT on many cars when cranking the starter.

It is not just cranking speed that is improved with better cables. When the amperage draw from the battery is high, the available voltage to the ignition system to create a good spark is reduced. I’ve experienced this personally on several cars.. Installing the heavy cables I’ve described made a huge difference in getting the big engines started.

See you at the Gathering this August?

Greg Long