- Home

- About Us

- Join/Renew

- Member Benefits

- Member Pages

- Log In

- Help

- Museum Store

Home Page › Forums › What did you do with your P-A today? › Modified windshield wiper system

I have made a new system to operate my windshield wipers that perhaps no one else will want to emulate, but for the record for anyone else in this pickle, this can be done. I was a bit freaked out to learn that once the upholstery was in my ’35 sedan, the only way to access the wiper system was to pull the upholstery away between the windshield and visors. On a post a few weeks ago I mentioned Rainex as the solution, but even so the idea of closing up the wipers without them working to some degree wasn’t acceptable to me. Someday the car might be in a state where an annual safety inspection is required (fortunately not now).

First some additional notes to add to the PASB 2020 issue No 1 that covered the relubrication and repair of Trico vacuum wiper motors. The gasket seal that sits on the paddle is mentioned but not discussed. This gasket seals off the vacuum from the reversing slide valve and the paddle seals when the wipers are parked. When it seals properly the only leak path when parked is the on-off slide valve. On mine, the gasket was leather and nowhere close to sealing. After 2 weeks cleaning and treating with Lexol it was still nowhere close to softening enough to seal, so I made a new one from neoprene rubber. At least this was successful. Another note, cruising the oracle of all knowledge (the internet), it seems that neatsfoot oil will soften but apparently accelerates long term degradation. Lexol seemed to be the favored choice for treating leather. Also, most oils and greases , including 3in1 will deteriorate to a gummy residue over time. Clock repairman do not use 3 in 1 but rather a modern synthetic that apparently is much better at resisting this over time. Synthetic greases are favored for the same reason.

After also treating my paddle seals with Lexol, polishing the slide seals, slathering copiously with synthetic grease and reassembling, my wipers worked for only a few minutes before stalling, even after wetting the windshield. I then contacted the expert to see about rebuilding my wiper motor and learned that the ’34-’35 Pierce sedan wiper motor was almost unique, only used on Pierce and a model of Buick. The pre-war zinc castings distorted over time and he has no parts to rebuild them with. He could only offer to basically re-grease it much as I had already done but no guarantee to would work for very long. He could replace the on-off slide seal with an improved version that would seal better and not throw off the engines idle mixture when the wipers are parked.

To me the Trico wiper motor was a clever design that made a lot of sense for open cars where the motor was compact, mounted directly to the windshield frame, accessible for repair, and not using a single motor to drive two wipers through gears and drive arms. It probably helps that the rotor faces down so that oil/grease may matriculate down to the bottom and have the paddle re-wipe it on every stroke. On the sedans the motor is upside down and if one tried to use oils to re-lubricate it would probably just drip down through the slide valves and stain the upholstery without re-lubricating the paddle.

I decided to modify the system using commercially available pneumatic cylinders that with well proven seals on circular cylinders and rods would have a better chance of sealing. Slide seals on straight surfaces is of course one of the reasons we aren’t all driving Wankels today. My first attempt was to add the cylinder attached to the drive arm and the vacuum was tapped into either side of the original Trico motor. This system was the least departure from the original, using the original valving system and just using the new cylinder to boost the force of the original motor. Alas, the leaks in the paddle seals were too great, and it accomplished nothing.

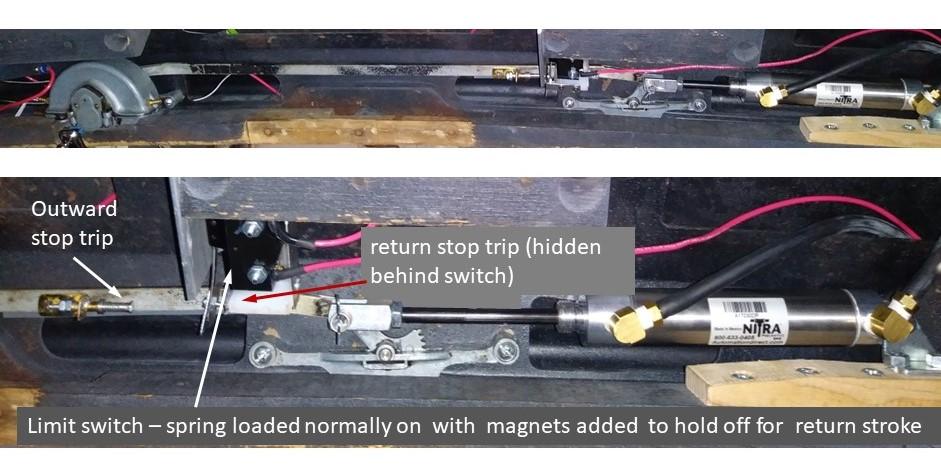

The final system uses electrically actuated air solenoids with limit switches to control the cylinder and the original Trico on-off slide valve is replaced with a switch using the original knob and trim molding. Operated on its own, the 1 1/6” diameter air cylinder had enough force to drive the wipers to a speed sufficient to risk eventual destruction of the zinc alloy drive gears, so throttling valves were placed in the lines to control speed. The control valve system is mounted to the firewall and will be accessible after the interior is installed.

<p style=”text-align: center;”> </p>

</p>

It is the brilliant reinvention of inferior components that maintain some element of sanity to car collectors. Good for you. I remember the “shame” that was put upon me when I replaced the points in my ’36 Pierce, ’47 Cadillac, and ’58 Cadillac all on the same day with custom made Pertonix ignitions. Guess what: In ten years your faithful member has not hitch-hiked in one time with any one of these cars. To boot, each of them start faster, has more punch, and makes me feel a lot more secure on a Sunday ride.

Thanks, I generally adhere to the notion that if it worked before it ought to be possible to make it work again but it was quite vexing in this case. Possible and pragmatic are often in conflict. I actually am not convinced that my casting is significantly distorted or that the valves are bad, I think the main problem is the leather paddle seals. New paddle seals are available for Fords but are smaller. They aren’t complicated, but could spend more weeks fiddling trying to make them with the close tolerance and very fine edge fit and finish required. I also considered trying to come up with a differant seal design but I have many more fish to fry.