- Home

- About Us

- Join/Renew

- Member Benefits

- Member Pages

- Log In

- Help

- Museum Store

Does anyone have suggestions about how best to address the stuck heater valve on my Model B? I’m wondering if there are any good schematics or photos of this unit, as I believe mine has been modified with some non-Pierce parts.

So far, I’ve heated/cooled this assembly and used a number of penetrating oils, but haven’t had much luck in freeing it. This has been going on for a couple of months. I address one system or another, and then come back to this valve and try to coax it free once again.

By the looks of the porcelain, this manifold was running rather hot in the past. I wonder if a lean condition was at fault?

Thanks in advance!

-Carl

Used my inductive heater and Ferrosol to resolve this issue. Was able to also confirm the shutter integrity and movement by removing the exhaust pipe plug and using a borescope/inspection camera.

Does anyone have a photo of a Model B with the rod/end connection to this manifold shutter?

Thanks in advance!

Carl,

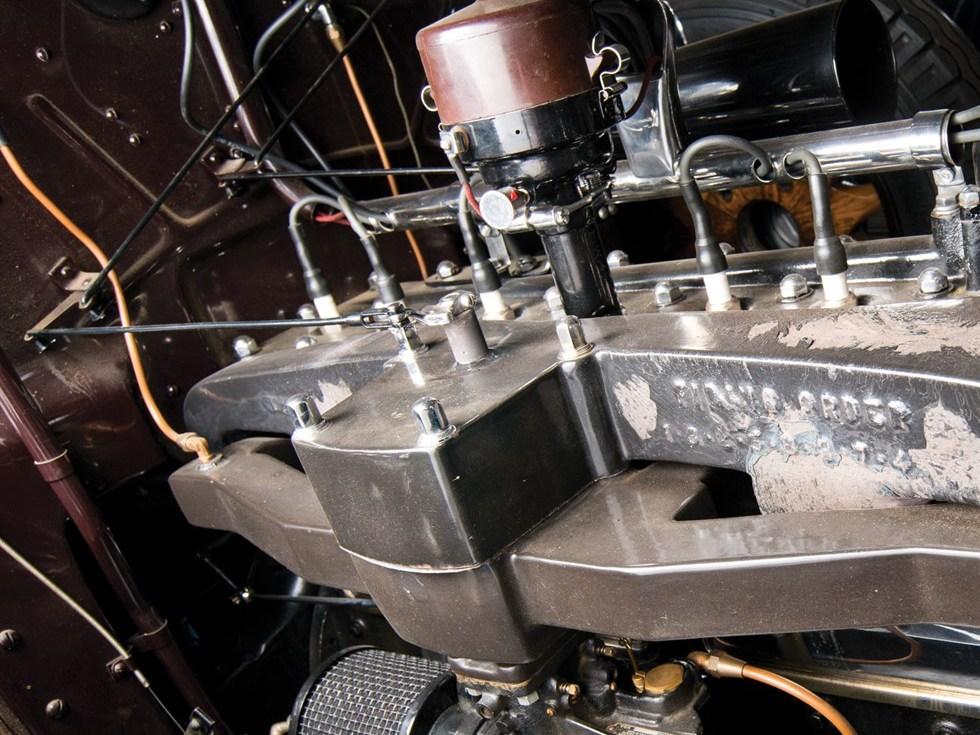

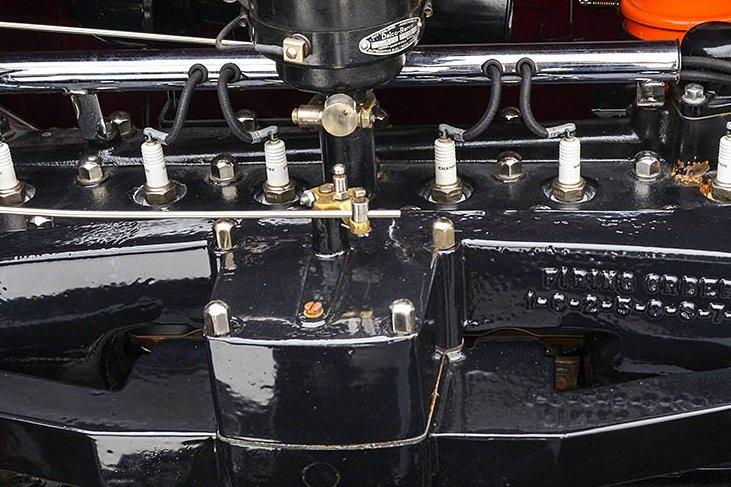

These photos are both of 1930 Bs. Two different methods of attaching the rod. I’m not sure which is correct.

Carl,

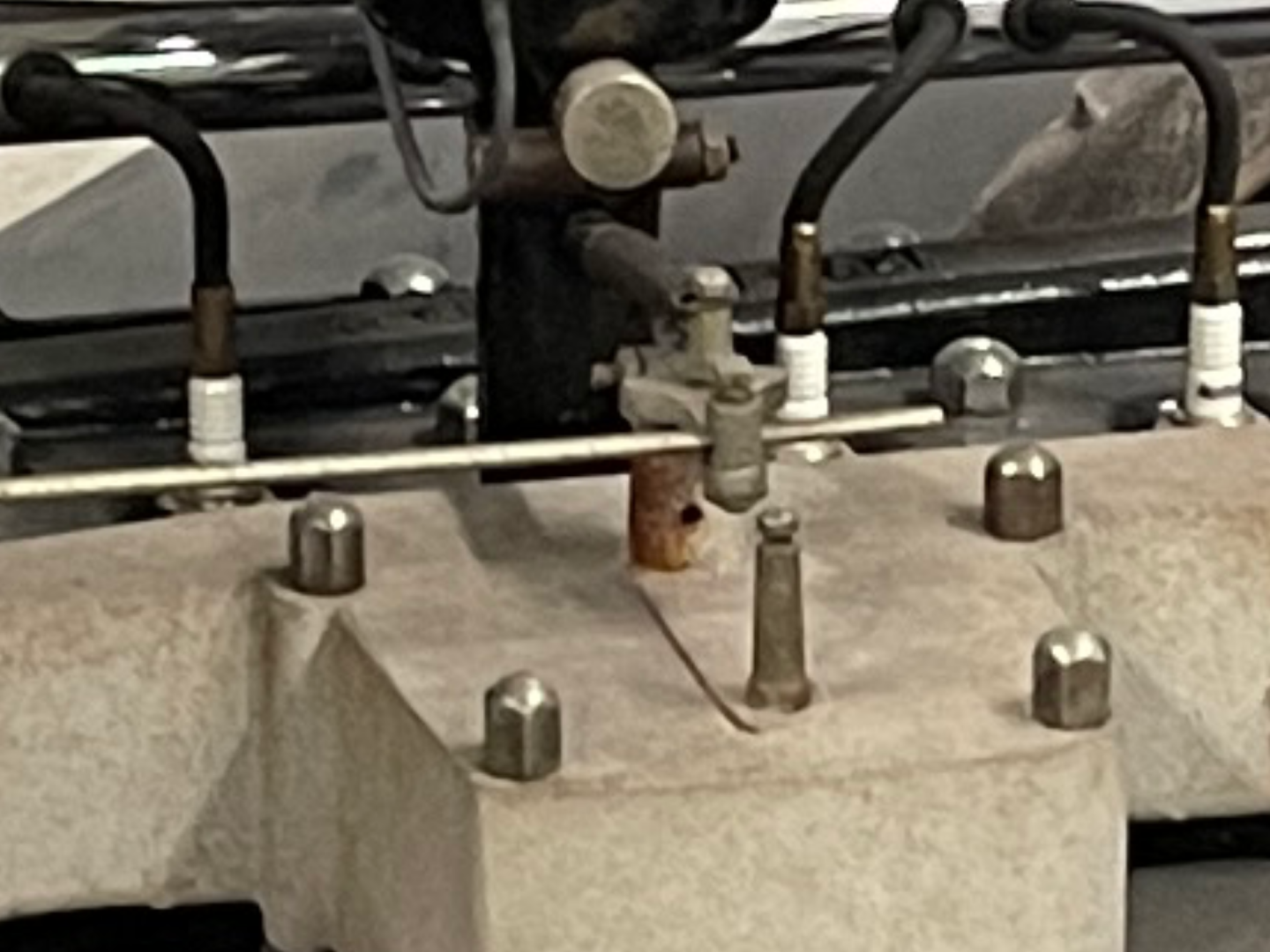

Here is a photo of my 1930 model B rod attachment. Not a great photo, but hope

it helps. The return spring attaches to the distributor base.

Tom Barrett

Appreciate the replies, Gents! My apologies for the late reply, as I’ve been away from the PAS forum for a while…

These photos give me a much better reference point – seems there were a few Pierce configurations (or creative restorers ; )

Hello Carl. If or when you ever have the manifolds off the engine and the two manifolds separated, many Pierce owners will instal a Stainless Steel plate between the two manifolds to reduce the heat transferred to the intake manifold..

When our Pierces were engineered and built, the gasoline available was pretty awful. It didn’t vaporize well and a well-heated intake manifold was used to aid in helping the engines to run smoother on a leaner mixture.

But with today’s fuels, very little intake manifold heating is needed. And if the manifold is too hot, the carburetor is also too hot and can cause the fuel in the bowl to boil.

When a solid SS plate is put between the manifolds, it helps reduce the heating of the intake manifold..

Greg L