- Home

- About Us

- Join/Renew

- Member Benefits

- Member Pages

- Log In

- Help

- Museum Store

Hello,

I am restoring a 1930 Model B with a Warner 3 speed transmission. I have 250 miles on it on the road. It originally shifted hard into the gears. The transmission was rebuilt and the clutch plates were rebuilt by the previous owner years ago. I have recently experienced noise in all 3 gears whenever the car is over about 5 mph in all 3 gears.

My next step is to put the car on car stands and run it to listen to the car in the garage without any road noise.

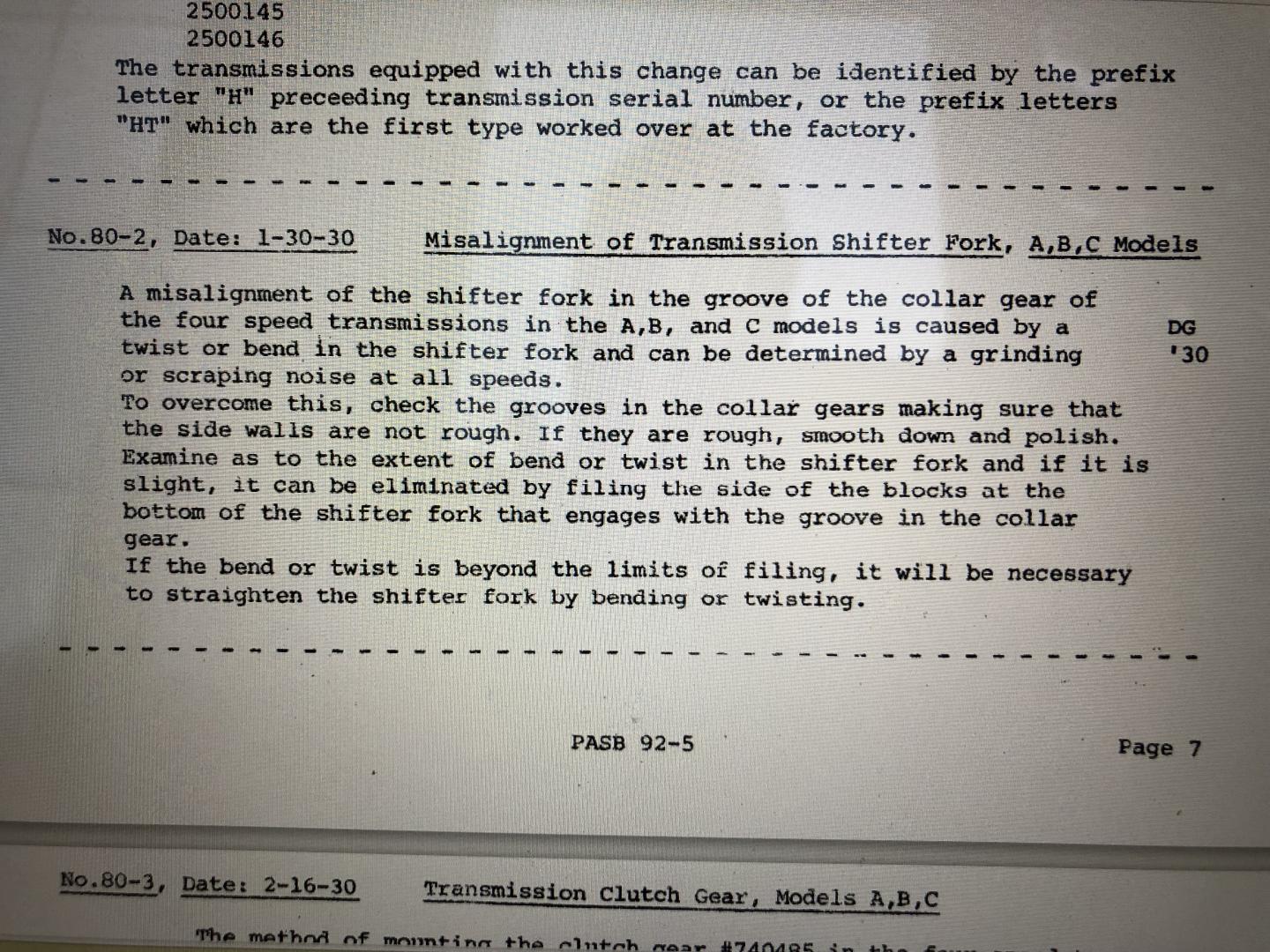

Below is a discussion that most closely describes the problem that I found is PASB 92-5. The noise did not occur when I first started driving it. My guess is that I bent the shifter. If it is bent the shifter I am wondering how to bend it back and how do I tell if that’s the problem. Any thoughts and suggestions are appreciated.

Dave

Dave,

WOW! That is interesting and it seems as though there is a simple solution that at worst could possibly maybe need a bit of heat.

Thank You PAS of your years of accumulated knowledge and willingness to publish it.

Keep us posted on your progress.

Peter

Hello Peter and PA members,

I have not got back to the transmission but now that its hopefully warming up I will be able to.

Just curious if anyone has run the engine with the shifter tower off? Not sure if it would hurt the transmission but it would confirm that the shifter is bent if the noise goes away when the top assembly is removed.

Take care,

Dave

Unfortunately I don’t know the answer to your issue but leaving the tower off has the potential to allow the gears to float around as the shifting forks will not be holding the gears in place. I would think they would possibly end up in a bad combination which would be worse for them. Then there is also the possibility of the gears slinging 600 weight everywhere without a cover.

Hello Mark, Thanks for your reply. My thought was to only run the car on car stands for a short interval without lube in the transmission box but have the gears with a slight amount of lube on them and the surrounding area well covered. I had seen it done with a farm tractor years ago. My guess is that the forks are bent and the cause of the noise. I hope to run it on wheel stands first and then take the tower off to see better what’s going on. I want to be certain that the forks are actually bent before i try and bend them and I’m also not real sure how far to bend them. Probably will be a trial and error situation. That said It will probably be clearer once i tie into it. I will keep you posted.

Take care,

Dave

David

The three speed transmission from 1930 is likely to be similar to the one in my ’29 and the parts book. If so, there are four things to check before doing something drastic to the shift forks.

(1) Operate the engine while on the jack stands is to see if the same noise is there in neutral; if so, one of the ball bearings may have a problem, allowing the teeth to not mesh on their proper radial line of contact.

(2) Check the ball bottom end of the gearshift rod, it engages the pockets on the shift rails. On an old Allis Chalmers tractor I had years ago, the shift lever engagement ball was quite worn out where it refused to fully engage with the shift rails; it required significant weld build-up to make it behave. (3) Are the shifter collars on the top of each rail worn out where the gear shift ball engages?

The other area is the shift rails to the rear of the shift tower where several potential problems can exist. (4) There is a detent ball and spring unit on the outside of each rail and a locking piece between the rails. There are three detent pockets on each rail; holding engagement into the forward, neutral and rearward position of each rail. These ball and spring units need to move freely [Is a spring broken?] and the detent pockets on the rails need to be gunk-free so the ball can engage properly to hold the gears in their proper axial engagement positions. A lock piece appears to float between the two rails to keep them separated while shifting and the ball is outside the detent pocket. If the lock does not slide freely or the ball does not seat properly into each detent pocket, the shifting will be difficult.

If the car has been sitting for a long time, some condensation may have cause some corrosion and general gunk on these parts above the oil level. If the rail does not shift all the way to the end detent pocket, the gear teeth are only partially engaged axially, which would cause some noise in each one. This inspection is pretty easy once the tower is off and does not involve operating the engine.

All these checks can be made before removing the collars and bending them; if you do pull the shift forks out, pay close attention to the wear marks on each side which should be equal, indicating even load is applied evenly on the left and right side of the fork. If wear is even, then these parts are not deformed or bent.

Best Regards, Herb Tull

Thank you very much Herb for your advice. I will check into your 4 recommendations and keep you posted on what I find. I have the carpet and floor out and hope to get back to it later this week when I have some help.

Take care,

Dave

I wanted to give y’all an update. I ran the car yesterday on jack stands. I ran it in all gears at various speeds. There was noise or unusual vibrations. I am going to run it on the road after the next rain and the salt is gone for a road test to see if I can pin point the source provided it is still making the noise.

Dave

Hello,

I wanted to give y’all an update on the trans noise. I have been driving the car this spring and the scraping noise that I thought was coming from the trans has not happened. So it probably was coming from another source. The noise was occurring anytime the car was over about 5 mph in any gear. I have had a couple of rough shifts where it bangs into gear or I have trouble finding the gears this spring on occasion. Prior to the recent trips I had run it on jack stands and could not hear the noise. The rough shifts this spring could caused be me and/or things getting worn in.

I had some time so I decided to open up the transmission based on the rough shifting and the previously noise concern. All seemed well with the gear box and shifter visually(please see the pictures). There wasn’t any metal chips in the lube. I was glad to see that!!! The gear oil I use is GL-1 (140 weight).

I have not had problems with it staying in any of the gears I select when I drive it just difficulty at times getting it into different gears on occasion.

Next steps are to put it back together and run it and hopefully get it to Hickory Corners in August for the annual meet.

Thank you all for your previous comments.

Dave