- Home

- About Us

- Join/Renew

- Member Benefits

- Member Pages

- Log In

- Help

- Museum Store

I assume the DELCO distributor on the 80 is supposed to have the typical ID tag; in any case mine is missing the tag. Does anyone know the model of the distributor? Are replacement tags available?Has anyone reworked another model with more readily available parts?

Just me, overthinking the situation…

According to the factory wiring diagram, 1925-26 used distributor/generator no. 300. 1927 used no. 17042.

Randy,

There is another Generator / Distributor made for the Series 80, it is a DeJon, however it is extremely RARE!

I have such a spare Generator / Distributor setup and have been searching for YEARS for a spare DeJon distributor rotor.

My Series 80 came with a DeJon starter and I was lucky enough to find a Series 80 DELCO starter.

You just need to search everywhere for the distributor cap, etc.

Peter

Randy,

Check out this eBay listing.

Actually the guy is listing THREE of the same caps.

I don’t know if they will work on a Series 80, but some others may be able to tell you.

You can also pop your cap and see if it matches.

If it does, these will go FAST now that the word is out.

Peter

http://www.ebay.com/itm/162431177812?_trksid=p2060353.m1438.l2649&ssPageName=STRK%3AMEBIDX%3AIT

Looks almost identical; at any rate thanks for the lead.

I was offered one nos in the box, $325; had to think about that a while.

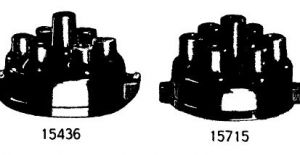

The Cap on Ebay might work but it is a different cap: the Series 80 takes a DELCO 15436 and the one listed is a 15715. I attach a Snip for a visual comparison.

I suppose then the generator-distributor has only one name-data plate, and my data plate is not missing after all. The number 300 corresponds to all I have found also.

Thanks!

Randy,

I am reminded that the Series 80 cap has a locking notch on one side of the inside circumference of the cap to keep it from squirming.

Oh well, it was a try!

Finding brush type caps is very difficult and although $325 is steep, it is likely the only cap you will ever need.

Peter

Randy: is your current cap bad? or are you looking for a spare to put on the shelf?

Generally, on antique cars, replacing a distributor cap is done only when it is needed, not just because

you are doing a ‘tune-up’.

The series 80/81 cap will last a very long time, if it isn’t cracked, even a worn contact ring will work fine.

Greg

Mine works fine, although it has had nail polish applied in a few places. I would like to eventually get a spare though. I have contact points coming.

Nail polish is a technique for fixing a cracked cap when the cap is difficult to find. Epoxy nail polish is preferred. Using a Dremel drill, drill a tiny hole at each of the crack to prevent further propagating of the crack. Open the crack slightly with a dental pick. Clean out with brake cleaner or electrical cleaner. Apply one coat (one brush stroke) of nail polish to the crack. Repeat about four times, preferably one day apart.

Hi Randy, dig out your VOM, set it on OHMs, and check the points pivot shaft in your distributor to the point plat it is mounted in. Some, I think most Pierce S80 distributors have an insulated pivot pin. There is a bakelite washer or busing on the end of the pivot or in the mounting hole in the plate..

BUT: there are two types of point-arms that look identical, One has a brass bushing that would work on an insulated points pivot pin. The other type has a fiber or Bakelite bushing to go on a grounded pivot pin, or an insulated pin. So check your distributor and find out what you have in it..

I worked on a car that had a brass-bushing point arm on a grounded pivot pin.. and it would run.. but it had odd misses, and when it got warm the missing got worse.. I thought it was fuel mixture related, or fuel supply.. but it turned out that the grease on the point arm/pivot would work well as an insulator when it was cool, but once it got hot, it shined out and would allow occasional electrical grounding of the point arm… Can you imagine the frustration I went through chasing THAT problem down ??

Regarding distributor caps: The 6 cylinder cap that is normal for a Series 80/81 has open brass lined sockets for the plug-wires to be pushed into. But there is an earlier cap, that was used on the Dual-Delco distributor on Pierce T-head engines, from the Teens through the Series 33. These distributor caps had threaded towers in the cap’s top surface, and there were threaded bakelite nuts with brass threaded insides that were slid onto the plug wire, the wire fed through a small hole in the nut, then the nut threaded onto the cap.. The slip ring inside and the rotor with the spring-loaded rubbing pin were the same.. The Dual Delco originally had a full circle rotor, it formed a sort of dust cover over the points and condenser, I believe to keep the dust from the friction ring from dirty-ing up the points and distributor cam..

Greg Long

I bought one of those DELCO 15715 caps to compare it to the 15436 that the Series 80 uses. Only differences I see: the 2 places provided for the hold-down clips are different; the bottom edge of the cap is not shaped to sit on the ledge machined on the distributor.

Other that these items, the caps seem identical.

Confirmed this evening that my Car’s pivot pin is insulated; the new points set I bought was in the mail box and the movable arm has a brass bushing.

Thanks Greg!

I’m glad to hear that the pin is insulated, that helps a lot.

Make sure the point arm has not friction on the pin. Did you get the hooked spring for the points ??

This hooked spring is much harder to find than the point arm or fixed point [on a threaded rod w/lock nut ]

I love how Pierce is so vague about the point gap setting: I think it is .018″-.027″” or something similar.

Greg Long

“

Randy, suggest you also replace the lock washer that holds the insulated pivot pin/post to the plate. You’ll have to remove the plate from the distributor body to do this. I spent many hours in 1996 trying to find a crippling ignition problem (OK at idle to 700 rpm, major miss under any kind of load), and the 1925 lock washer had fatigued and allowed the post to wobble just the slightest amount, actually almost undetectably, but a point adjustment wouldn’t hold. Most of us are used to point posts being pressed into the plate; these aren’t.

As to Greg’s comment about the wide range of point settings, bear in mind that the fiber rubbing blocks on new points of the era wear a LOT in the first thousand miles or so, then stabilize. I set new S80/81 points 0.024 and used ones at 0.020-.021.

Good information! Thanks, Friends!