- Home

- About Us

- Join/Renew

- Member Benefits

- Member Pages

- Log In

- Help

- Museum Store

Home Page › Forums › What did you do with your P-A today? › Crank is in

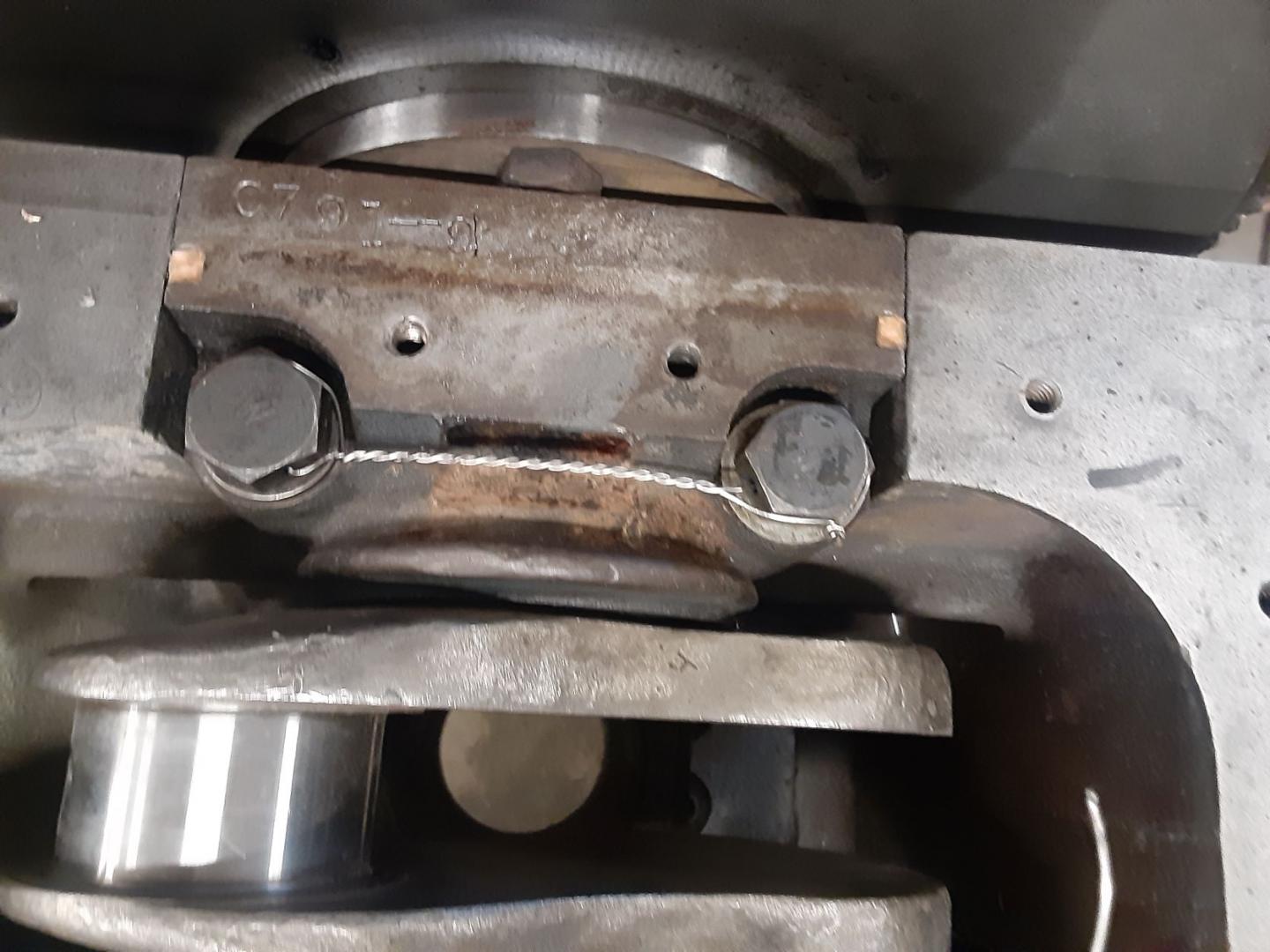

Got the crank in over the weekend. Turns great, just need to install some rod bolts. On to the rods.

This is the stroked crank from a ’35.

Ultrasonic cleaner really does a nice job of cleaning these

Looking good!

Today I decided to safety wire the main bolts.

I adapted my safety wire pliers so I could use my drill to twist the wire.

I cut off the twisted rod that spins the pliers and inserted a headless bolt into the hole and welded it in place.

I am using .041 stainless wire.

First, make sure you have enough wire, 2X distance between bolts plus additional to compensate for the intermediate and final twists.

You are going to route the wire in a reverse “S”. After running the wire thru the hole make sure the righthand wire passes under the lefthand wire to start the clockwise winding. The theory is that you want the wire to go into tension if the bolt starts to unwind.

Pull the wire tight and approximate where along the length it will reach the opposite bolt and clamp the spot in the pliers.

Rotate the plier/wire with the drill in forward until the wire is twisted. Some recommend 7 twists per inch, however you measure that!

Pass the free end thru the other bolt hole and repeat the twist. Some say you should make the second twist counterclockwise, but I am not sure that makes a difference. With the drill you just put it in reverse to do the counterclockwise twists. Cut off the excess and bend the resulting pigtail down.

Finished wiring, on to the other 8.

Bill, These pictures of your engine work look really good and show the progress you have made. So, congratulations! The tie wires are inside the oil pan and totally out of sight where nobody is ever going to inspect, so measuring twists with your eyeball is quite sufficient.

For us nut jobs who are REALLY hung up on having EXACTLY the recommended twist in tie wires, we first need our heads examined. However, if we still INSIST on verifying the pitch, there is an easy method. The UNC scale shows both 1-1/8 and 1-1/4 inch bolts using 7 threads per inch. Most thread gauges do have a blade for 7 threads (or twists) per inch, as well as many others.

Please keep us posted as your adventure progresses. Herb