- Home

- About Us

- Join/Renew

- Member Benefits

- Member Pages

- Log In

- Help

- Museum Store

Is there any evidence of what Lloyd used taking car of the car for so many years in the garage?

Robert,

I think we are pretty much in agreement on all of it. I am going to try to stay with oil at the 800PPM level. The link below is to an article by a GM Engineer on oil myths, just in case you haven’t seen it.

Dave

David T.,

There was little evidence of what was done to the Pierce in Lloyd’s old garage. I drained the oil and then used a thin piece of plastic shaped like a hook and scraped the bottom of the oil pan and I did not see any lumps or sludge. I had looked over several AACA and car enthusiast sites, and found so much conflicting information on the best type of oil for antique cars. Of course I came to the PAS, for more Pierce specific information and guidance.

Ryan, I think you did the next best thing to dropping the pan.

More than 25 years ago, I acquired my first Pierce, a Series 80 sedan, from its owner of 38 years but the car had only been run in place in a barn very occasionally for 15 years. He did tell me he ran non-detergent oil. I knew I didn’t have time to drop the pan in the near term, I got it hot, drained the oil, and added 3 qts cheap detergent oil + 6 qts non-detergent. I changed the oil after 200 miles, examined it carefully (no chunks/bits of debris), then installed 6 qts of detergent + 3 of non-detergent–and ran that 400 miles before a hot drain and a full detergent refill. A year later I finally had time to drop the pan and found minimal sludge but some occlusion of the oil pump pickup screen. At that point I did a thorough interior cleaning. That process may have been overkill, but the peace of mind (see my comment above) was worth it!

It’s well worth paying close attention to your oil pressure gauge at all times. If gauge readings change suddenly, check out the cause promptly.

By the way, I had a chance to look over your car at the NE Indiana Meet last year, and I love it! You hit a home run with that one!

Bob,

Thanks, I would like to see the article and will publish it in the PASB as long as that isn’t a problem with CCCA.

I also am skeptical that detergent oil will loosen “chunks”” of deposits that occur when an engine has previously run on non-detergent oil. I would love to see a “”real”” study on the subject.

Dave

“

Speaking of concern for loosening or removing oil sludge, I heard an interesting story from an older mechanic on how oil changes were done back then (prior to oil filters). For an oil change, the oil pan was dropped, the sludge was scraped out of the pan and then kerosene was poured into the oil filler tube to “clean any out sludge or oil residue in the oil passagesâ€. The oil pan was then put back on and the engine was filled with fresh oil. Can anyone corroborate this as being true?

Robert

This is an interesting discussion, and very useful. To add a twist, what is the general thought about using synthetic oil in our engines? Mine is freshly rebuilt, so based on having done this with a dozen or so new cars and newly rebuilt engines, I run non-detergent oil for several thousand miles, then switch to synthetic. My diesel truck has 250k on it, and none of our modern cars have had any engine oil related issues ever. I just had the C4 transmission rebuilt (after sitting for 45 years) in my first day of production Mustang (serial 100626), and the transmission shop told me to use any form of synthetic fluid I want, as long as it is synthetic.

Thoughts?

To answer Bob Coates question about synthetic oil: You CAN use synthetic oil in our engines. But it pretty much is wasted money.

Synthetic oils have one main advantage: they are more viscosity-stable over a wider temperature range than conventional oils..

Since most engine wear occurs during the first few moments of starting a cold engine, a synthetic oil will flow, splash and squirt much better for this critical cold-start situation. Which reduces engine wear.

BUT we rarely will start our Pierce Arrow engines at sub-freezing temperatures. We probably rarely start our engines at less than 40*F.

In the over-the-road Trucking industry, it is a sort of ‘rule of thumb’ that one cold start equals 5000 miles of highway wear. THAT’s a LOT of wear. To prove this ‘rule’ it is easy to look at the maintenance records of the typical over-the-road truck engine. It is rare that an engine has to have any major internal repair before 1,000,000 miles.. yes a Million miles.

Our daily driver cars that start in the morning, are driven say 50 miles to work, shut down then the process repeated that evening, are lucky to go 250K miles. The reasons are not just how heavy duty the big diesel truck engines are, it has to great extent to do with the multiple cold starts.

I have a Kenworth expediter truck, which is my car-hauler when I want to drag two cars to an event. This truck is a 2007, had 1,121, 000 miles on it when I bought it in 2015. I have every maintenance record for the truck.. it has never had any internal engine work. NONE. And it currently uses a quart of oil every 4-6000 miles..

The reason is the number of miles put on during 2007-2014 [when it was put up for sale] Seven years to put over a million miles on the engine, that’s roughly 143,000 per year, or 12,000 per month. So you can see the truck was on the road for most of it’s life.. It got regular monthly oil changes: about every 12,000 miles.. and the oil was conventional 15w-40 oil. Either Shell Rotella T, or Mobil’s equivalent: 15w-40 Delvac.

So for our Pierce engines, I use conventional oils. they do a fine job for our pampered collector car engines. If I were to use my Pierce as a daily driver, in ALL weather conditions.. I might consider using synthetic oil.

Greg Long

David, in your research I would be interested if you run into any data on the viscosity of multi-grades at elevated temperatures – 300 to 500 degrees. I thought I found some a few years ago but now can’t seem to find it.

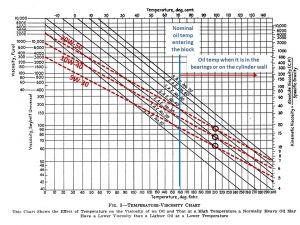

If one takes the basic definitions of multi grade such as 10W-40, it has the same viscosity as SAE 10W at 0 degrees F and the same as SAE 40 at 210 deg F. This is shown on the chart – note that these charts are highly non-Cartesian on the y axis – straight 30 weight is about 50 times less viscous at 210 F as it is at 60F. Extrapolating this out would indicate that 5W-30 would have higher viscosity at 300 degrees than SAE 40 straight weight. This is relevant because the temperature of the oil film at top dead center will be closer to the temperature of the inside surface of cylinder wall at the top of ring travel rather than the bulk temperature of the oil in the pan when it enters the oil pump. This is greater than 300 degrees and a 5W-30 would actually be thicker at TDC and reduce the metal-to-metal boundary lubrication that cause the upper cylinder wall and compression ring to wear (tapering the bore). Note that ’30’s Pierce recommended nothing thicker than straight 30 weight in summer. This also holds true for the bearings – the local temperature of the oil film in the bearing will be hotter due to the local friction than the bulk oil temperature. meanwhile most of the oil in less critical areas will be less viscous, creating less heat and friction – an advantage of multi-vis.

The question though, is that it may be misleading to assume the oil viscosities will extrapolate above 210 as I show in the chart, so if you run into any data for elevated temperatures I would appreciate any links to it.

Jim

Jim,

I haven’t run across anything, but will keep my eyes open.

Dave