- Home

- About Us

- Join/Renew

- Member Benefits

- Member Pages

- Log In

- Help

- Museum Store

The discussion below about lubrication mentions using 20W-50 weight oil. At the risk of starting a long debate, I think there is a natural tendency to use oils that are too thick. Thick oil produces more friction that creates more heat. Besides reducing power and increasing cooling water temperatures, thick oil will also increase the temperature of the critical connecting rod bearings where a shortcoming of babbitt is reduction of strength at high temperatures.

My 1935 P-A owner’s manual states; “Any oil heavier than S.A.E. No. 30 is not necessary or recommended.” For breaking in a new engine: “For the first 500 mile period, an SAE no. 20 or 20W oil will be to advantage…Continuing to use the S.A.E. No. 20 or 20W oil until 5,000 miles or more are reached has certain advantages in respect to the maintenance of the engine power, but the consumption rate will be slightly higher than with an S.A.E. No. 30 oil.”

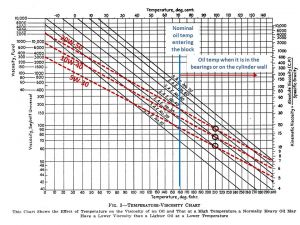

This was before the advent of multi-viscosity oils. I have added a plot of the viscosity of the different grades of oil. Note that these plots are highly non-linear and cover a change in viscosity of SAE 30 from 100,000 at 0 degrees F to only 40 at 300 degrees F!

The “straight weight” oils used prewar are far from constant viscosity. Note that changing the temperature of 30 weight oil from 70 degrees to 210 degrees reduces viscosity by a factor of 20/1. A benefit of multi-viscosity oils is a mild reduction in the dramatic thinning of oil as it gets hotter. Oil that starts out at a temperature of 160 when it enters the block will get heated as it travels through the engine. When it reaches a connecting rod sliding at high velocity it will heat up locally to temperatures higher than average oil temperature. The oil film at the top of the cylinder of course gets much hotter. Our Pierce-Arrows have very large bearing areas and very large piston skirt areas that were designed to deal with thin oils but generate a lot of friction and heat. A thicker oil will generate more heat and higher bearing temperatures and shouldn’t provide any benefit to an engine in reasonably good condition. The limit may be defined by the hydraulic tappets, if they are worn or leaking such that they won’t stay quiet within the recommended oil viscosity range.

The advantage of multi-viscosity is that an oil similar in viscosity to the original recommended straight weight at the average oil temperature will have similar average friction but will retain more viscosity in a local hot spot such as a heavily loaded connecting rod bearing being lugged at low speed after a hot summer highway run. Looking at the charts a 5W-30 would have similar viscosity to SAE 20 at a nominal 160 degrees, match SAE 30 at 210 degrees, and exceed the viscosity of SAE 40 if a local “hot spot” goes over 270 F.

In other words, 5W-30 is actually thicker than the oils recommended by P-A at the high temperatures where it counts. If the hydraulic tappets won’t stay quiet on 5W-30 then the next stop is 10W-40. I think 20W-50 and/or STP are last resorts to quiet hydraulic tappets.

For the case of cars with overdrive or tall rear end gears heavy oils are less risky since oil temperatures rise with RPM.

Great info.

Thanks for posting.

I will definitely keep this in mind when I purchase oil for my next oil change.

Fantastic information!