- Home

- About Us

- Join/Renew

- Member Benefits

- Member Pages

- Log In

- Help

- Museum Store

Home Page › Forums › What did you do with your P-A today? › Ran When Parked – 70 years ago

Tagged: 1702, 1937 Special 5P Sedan, restoration

I decided I needed another project to keep company with the other 4 ongoing ones – and I blame PAS for providing such a great experience at my first national meet this past summer for the decision to get another Pierce. Emporium recently had few projects that appeared and after talking with the various folks involved, I purchased a 1937 V12 out of Washington. The car had been purchased by the owner as a young man in the early 60’s and he carted it around everywhere he went with the intent of restoring but after 60+ years he just hadn’t been able to get to it and now was in failing health. It arrived here in NC a few days ago and I took the opportunity of a free weekend to get started sorting the bits and pieces and figuring out what I had – or didn’t!

It’s engine #409065 and has a body tag 544-S-18 on the 144 inch wheelbase. It’s remarkably complete, solid, but it will need absolutely everything. Nearly everything is there with the exception of one large and one small headlight lens, the heater/defroster fan unit, the jack, and the outer ends of the front bumper; it had a radio and that’s there as well. The missing headlight lens’ are a bit worrisome as they seem to be difficult to find.

So, this is a “New Special Five-Passenger Sedan” as the Pierce termed it in the “Special Custom Body Group” section of the 1937 brochure. I do not see another listed in the vehicle roster, so is any one aware of another? Or is this possibly the lone survivor? Another question I have is what made this “special” – is it simply that Pierce put the Salon Twelve 5P body on the 144 inch wheelbase? In any event, the (likely long) restoration process is kicking off!

Hi Frederick,

That car is not listed in either the PAS files or the Weis files, so it was an unknown to PAS car. The Weis files estimate 23 1702 144″ W.B. cars of all body styles were built with 7 extant (now 8). One other 1702 5 ps. sedan is shown as existing. However, elsewhere in the records it indicates it is a 7 ps. so yours may be the only 1702 5 ps. remaining. There is a 1701 5 ps. listed in PAS records.

In the two 1937 brochures I have access to, in one the Special Five Passenger Sedan is listed as a standard body, in the other it is listed in the “Custom” body group.

I am going to add this car to your PAS record. Have you checked the front frame rails for a Serial Number Plate?

Good luck on the restoration.

Dave

Hi Frederick I have a 1937 model 1701 5 pas. Club sedan but it is a pice of crap not worth much only building a rat rod out of it if there is any thing left you need I give to you for free because the car is free to me.

A few items – and as can be seen lots of work ahead!

Hello, Frederick:

Looks like a good restoration candidate to join your 1919 in the stable!

Have you done much surveying under the hood yet, and are the major components there? If it’s been parked since the mid-’50s, any word about why? If you have access to a borescope, it might be a good idea to remove the plugs and do a little investigation. A 50/50 mix of acetone and ATF wouldn’t hurt to pour into each cylinder and left to soak.

When you’re at the point of removing the oil drain plug, do check the oil quality and condition. (From an aircraft standpoint, we cut filters during every oil change and examine the pleats for residue/metals as a matter of caution, so sorry if I seem a little in earnest.) When you’re at the point of the oil pan removal, be sure to clean/check the oil pump tolerances and have a good look at the rotating assembly. Water jacket covers’ integrity and internal block cleaning isn’t far behind… Not trying to dictate your restoration moves, here, but only offering a little helpful advice if you like. The condition and health of that 12 might be your first priority.

-Carl

Hi Carl, many thanks for the advice! All the major components are there – generator, starter, water pump, oil cooler, distributor, carbs, etc. All the caps to the radiator and oil fil are there, but the carbs have their butterflies open and it would be no surprise if a fair amount of debris hasn’t gotten inside. Fuel pump is there and no residual gunk in the glass bowl. I have not tried to see if I can turn the motor by hand, but I am going to say I doubt I will be that lucky. The current plan is to remove hood cowl and fenders for access and soak all the nuts/bolts/connections with penetrating oil and then start to remove the accessories. It’ll need a good soaking just to get the plugs out. I have access to borescope so will probably. I also have a nice new induction heater for all those frozen bolts that I am dying to try out!! In all likelihood I will do a full tear down and rebuild. I don’t know why it was parked originally as the owner is elderly and in a nursing home so communication is through intermediaries and not the best; I am trying to get as much history as possible.

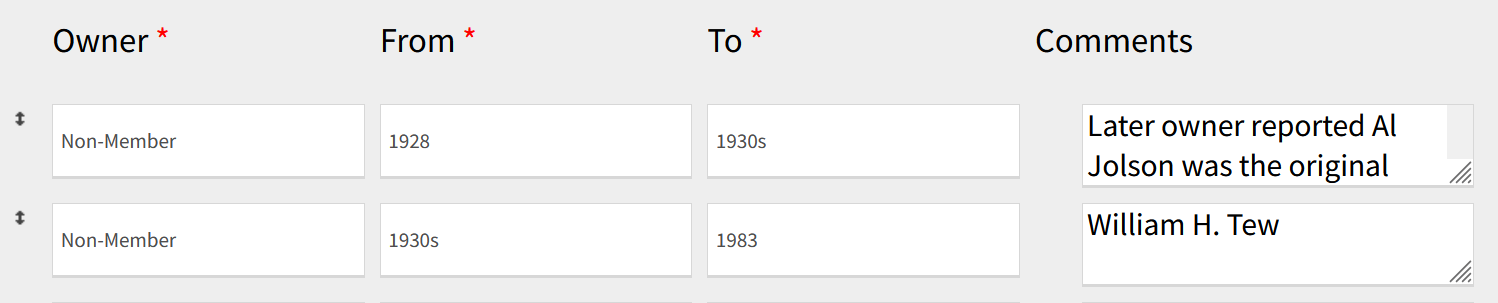

Thanks, David. Given it may be the only example, nice to think that this one beat the odds and survived the crusher! No chassis plate at this point, but it may be still hiding in storage as I sort things through. I’ve tried to add some of the prior owner’s names, btw, to the car entry on the roster, but it auto-populates with “non-member in the name field and will not allow me to edit.

Best,

Fred

Frederick,

Type their name in the Comments Box. on each line in the history section. Or you can send me the prior names (and years and location if you have them), and I can get them entered. It is a little tricky. Clicking on my name on this post should give you my e-mail.

That car is going to be a lot of work but should be a great car once done.

Dave

Part of the inventorying that you’re doing is through all those photos. Keep up that photo-documentation process and start a journal with notes about how you found the components. It doesn’t hurt to create some index marks and observe those that are there on the critical external/internal components. The inductive heaters are very helpful, and especially after heating and introducing penetrating oil. If paint and other finishes aren’t a concern, heat + 50/50 acetone and ATF can be a real help. Sometimes I like to combine that inductive heat with an inverted computer duster spray can to freeze a part rapidly. Hot+penetrating oil+cold breaks and lubricates for removal. Just be careful treating cast iron in this way, as it can be unforgiving. (Patience and knowing when to walk away for a while is also key!)

The two water jacket bolts that I broke on my 1930 8-cyl. were the ones that I used heat and penetrating oil on, and then finessed by hand – turning back-and-forth in removal attempts. Since I could see an awful trend emerging, I thought I’d try heat and penetrating oil again, and then a 1/4″ impact with a series of short “raps”. This rap-vibration/pause/repeat combination was a success, and the rest of the bolts came out without issue. Maybe this method will be of some use to you…

None of these recommendations are really original on my part. If you search various components and service through the PAS resources, other members have been in the same situation, or worse. As for water jacket bolts, Greg Long’s comments and recommendations come to mind. I believe he even filled some troublesome blocks with diesel or kerosene to allow a for a good oil soak before fastener removal attempts.

To borrow again some tricks from the old steam engine/tractor crowd, and old-school aircraft mechanics, and wrenching sailors, wintergreen oil can be helpful for soaking rust-seized components – piston rings and the like. You can get a similar combination from Marvel’s Mystery Oil, as I believe the main ingredients are more or less refined petroleum/Stoddard Solvent, etc. (I’d venture that the sweet smell in MMO is wintergreen oil.) Machinists also swear by Kroil, and I’ve had success with it, but more so with Bilt-Hamber’s Ferrosol, which is an English import.

After you secure that borescope and do some cylinder inspection, you’ll have a better sense about how to proceed. With those choke butterflies open there will be some debris/intrusion, but the throttle butterflies will still likely be closed. If you remove the plugs and find heavily rusted cylinder walls, I’d caution against trying to force the rotating assembly. At that point, an overhaul and inspection may be the best course.

I would drop the pan and remove the oil pump before trying to turn by hand, my 35 Eight was stuck and fortunately didn’t romp on it too hard as the hangup was actually a small bit of rust particle jammed in the oil pump gearing.

Thanks, everyone for your comments and assistance! Jim – interesting on the oil pump, hadn’t really thought about that as a source of a “stuck” engine… In any event, I’ve cataloged what might be missing and have already snagged a few of them online, and spoken to John about some other bits and pieces. Looks like that missing left driving light/auxillary light lens is going to be the biggest treasure hunt.

One question for everyone, what is known about the defrosting (and I presume heating) system on the ’37s? In speaking with John Cislak, he seemed to feel this was never offered by the factory and said he’d never seen one. The ’37 catalog clearly points out the defroster vents in talking about the new for ’37 instrument panel, and I have the vents and corresponding ducting under the dash and through the firewall that very clearly appears to be a factory item and not an add-on. There is also what appears to be a device on the exhaust pipe to capture hot air. However, the ductwork and whatever blower or fan to move the hot air collected from the exhaust pipe to dash duct work is missing. Does anyone know what the complete set-up should look like?

Fred,

Contact Bob Koch in Washington. He has a ’37 1703 that he restored and may be able to answer some of your questions. His contact information is in the Member Roster.

Thanks, David.