- Home

- About Us

- Join/Renew

- Member Benefits

- Member Pages

- Log In

- Help

- Museum Store

The end of the thread on 1935 845’s diverts to a discussion on bearings and rebuilds. I think that .015 should be considered the minimum acceptable clearance with .002 being a good target. J. F. Taylor was one of the great “grey beards†on internal combustion engines having spent a career in engine test labs and pouring over engine research reports. He wrote the seminal text “Internal Combustion Engine in Theory and Practiceâ€, while a professor at MIT and has the following comment on bearing clearance:

“The usual recommendation for crankshaft bearing clearance is .001 times the journal diameter. The author’s experience, confirmed by most bearing experts, is this is a minimum value, and that values up to twice this amount are acceptable and often desirable. Small clearances are dangerous both because they do not allow enough for distortion and because they have less safety against wear and scoring by foreign particles…bearing coefficient of friction decreases as clearance/diameter increases.

The objections to large clearance include lowering of the value of the Sommerfield variable and hence a lower factor of safety against oil film breakdown. However, most bearings fail for reasons other than direct oil film failure. The present author cannot recall a bearing failure due directly to excessive clearance, whereas he has seen a great many bearing failures attributable to inadequate clearance….No journal bearing in any engine, no matter how small should have a minimum clearance less than .001 in.â€

Pierce-Arrow 8’s connecting rod journals are 2.25†diameter and the clearance allowances are .001-.0025â€, the Pierce maximum clearance/diameter thus being at Taylor’s minimum. The basic reason car manufacturers specify extremely tight clearances: minimizing engine noise. It isn’t for bearing life.

The amount of heat a bearing generates is a function of the speed and clearance, tight clearances run hotter regardless of load. Babbitt of course weakens significantly with high temperatures. It was abandoned through the 1930’s for copper-lead inserts when sustained speeds over 50 mph became common. The importance of heat rejection in bearings is underscored by the appearance of cooling fins machined into the big ends of ‘30’s senior Packard’s, an extra expense probably not done for giggles.

Taylor mentions Sommerfield variable and oil film breakdown. This is basically the combination of bearing surface velocity, oil viscosity and clearance that determines how much load the bearing can resist before the surfaces of the bearing start scraping each other – leading to rapid failure. At highway speeds the bearing and oil gets hot and thin but the high speed has lots of margin to avoid breaking the oil film. Oil film breakdown and bearing damage is most likely at low engine speed, hot engine and high load – e.g pulling away from a stop with lots of throttle and low rpm after driving on the highway. Demonstrating the ability to accelerate from low speed in high gear being the worst case. Although bearing failures may manifest themselves at highway speed, the original damage instigating the failure was quite likely created before the final failure at low speed and may have nothing to do with the age or quality of the bearing.

I believe it is quite likely that thinking extremely tight clearances are a good thing has led to many failures rather than preventing them. If you run super tight clearances you better be absolutely certain that your journals have out-of-round measured in tenths of thousandths and that your rod bearings sit dead flat on their pins without any angularity or taper through every crank angle. My 845 had crankpins in good condition but the con rods had been rebabbited. Initial inspection measured .001-.0015 clearance. After reinstalling the caps and turning one revolution the babbitt would show bright spots where they were binding with no clearance at some point. Even if perfect, a tight clearance will run hotter than with a safer clearance.

I think the risk of failure of rebuilt engines with extremely tight clearances is evidenced by the clearance built into insert bearings for rebuilding later cars. When I rebuilt my ‘60’s Chryslers the crankpins were in good shape and were still standard. The new standard size inserts were .003 clearance – greater than the clearance of the originals with 100,000+ miles!

Babbitt is extremely sensitive to any impurities and contamination when cast, so the quality control of whoever is rebabbitting is critical. I suspect many babbitt failures are due to inadequate quality control by rebuilders. The pictures shown in the thread look more like poor bonding in the babbitt casting process to me.

Using high viscosity oils also compounds the problem of excessive heat and bearing temperature. Note that in the 1930’s Pierce-Arrow recommends nothing thicker than SAE 30 in summer temperatures. Ab Jenkins was running SAE 20 for his high speed endurance runs in the Bonneville desert – note I suspect he had high idle speeds to keep his engine running at idle with the high valve overlap of his “souped up†twelve.

Jim

Very interesting, Jim. Thanks very much.

My figure of 0.0015″ for clearance is at the minimum, of course, and I would not go below that for all the reasons you state. And I do agree that 0.002″ is fine and have heard that slightly larger can be OK as well.

(Note — what I know, I’ve been told by a well regarded professional rebuilder of vintage engines. I’ll share his name privately, if you’d like).

Do you agree about Babbitt becoming brittle and more prone to failure with age? Again, this is what I’ve been led to believe and have seen several cases. And I agree that in the photos posted on the 845 thread, it is adhesion to the rod this is the problem. But that Babbitt which came off in large chunks was indeed very crumbly and brittle. Not at all pliable as new Babbitt would be.

I also agree about oil viscosity. A thinner oil will cool better, and the resistance to shear of a thicker oil will generate heat in a very tight clearance. It is my opinion that in a worn engine a higher viscosity oil will provide cushion against excessive clearances and piston slap. Likewise if your driving habits include a significant amount of low rpm pulling — making use of the torque — a higher viscosity oil will be more resistant to fluid film breakdown. In my engines, I’ve run 10W-40 for this reason. Sometimes I wonder if 10W-30 would be better but I do find myself lugging the engine perhaps more than I should. Accelerating from slow speeds in high gear is satisfying.

Thanks again for your thoughts on this important discussion.

— Luke

Luke, I am unaware of a characteristic of babbitt just failing because of just sitting around for decades protected in a more or less closed crankcase but I am no expert on the chemistry of babbitt. I do have the feeling that babbitt failing just from old age is an urban legend based on theorizing about failures that occurred for other reasons, but would be happy to be pointed to an authoritative reference that shows otherwise. Perhaps someone has some reference data on this. I can imagine there could be chemical reactions generated by acids or water in the the oil that could effect the babbitt in some sort of corrosive process. Perhaps there is some extremely slow reaction that occurs with age. I can’t claim to know but would like to.

My personal experience is with copper lead inserts which is of course not spot on here. My ’36 Packard sat in a Massachussets junkyard with very serious rust/rot exposure from the late ’40’s to late ’70’s. New inserts for rebuild have long been a big problem for senior ’30’s Packards, but my inserts were in surprisingly good shape. My crankpins, however, were worn .004 out of round from the new (in 1934) harder copper lead insert material. I had the crank hard-chromed back to standard and used the original inserts. They had 56000 miles in its first life, they are 82 years old and still in the car with something over 25000 more miles of hard driving (including lots of 65+mph on the interstates). I have been more worried about the crank cracking from the hard-chrome stress concentration in the crank cheeks than from the bearings failing. Of course the cam and main bearings on my Packard are babbitt and just as old and have not failed yet either. They aren’t as highly loaded or run as fast as the con rods of course.

I guess by not spending anything close to $25000 on the rebuild it was supposed to fly apart a long time ago.

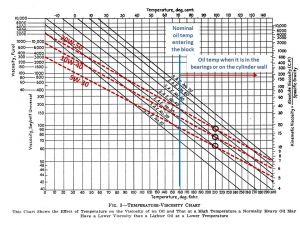

I have always used 10W-40 in the Packard but recently switched to 5W-30 after thinking about the 845 Pierce and keeping its babbitt bearings alive without overdrive or a high speed rear end. The 845 has the additional complication of keeping the hydraulic lifters quiet at idle if the oil gets too thin. A 5W-30 oil has the advantage of being thicker than straight 30 or 40 when the oil film in the bearings or on the cylinder wall goes over 250 degrees locally while the bulk of the oil is still at crankcase temperature. The oil temperature regulator on ’30’s Pierce and Packard’s was an addition that basically tried to control viscosity the way multi-vis oils later did.

The chart is from a 1930’s SAE report on the oil temp regulator with my approximations of multi-vis oils spotted on.

Jim

Hi Jim, I don’t think the very thin babbitt layer on an insert bearing shell has the same aging characteristics as the thick, poured-babbitt bearings.

In my experience, with disassembling a lot of old engines, the thick poured babbitt would often have cracks, and chunks missing. Most of the time, if a chunk was missing, there was a trace of babbitt on the steel rod, or rod cap. So it was not adhesion to the steel in these cases, but failure of the babbitt to stay intact.

It is quite possible that there is some expansion/contraction action that contributes to the cracking of thicker poured babbitt, that is not a factor with a .005″ thick layer of babbitt on a shell insert bearing. This is just a wild thought that I just had.

I have had so many engines with nice running characteristics, no noises, good oil pressure etc, but when the pan is dropped, and the rod’s inspected, there often is significant cracking, and hunks missing.

I suspect that many engine failures are due to unknown to the driver badly cracked bearing babbitt, and not having any indications such as low oil pressure or noises, the engine is driven normally or hard, and once the babbitt fails enough, then there is steel-to-steel contact and the rod and crank are damaged.

I have a ‘chamber of horrors’ in my shop with damaged rods that have missing chunks. I’ll post a photo.

Greg Long

Greg, your pictures look like poster children for one of the problems/worries on P-A con rod bearings. Studebaker engineer Sparrow in 1935 “Problems in the Development of a High Speed Engine” noted:”The first rods had babbitt flanges on the sides and cracks in the bearing surface proper would frequently extend to these flanges and cause large pieces to fall out. This would permit the cracks in the remainder to spread and bearing failure would soon follow. Considerable improvement resulted from the elimination of the babbitt flanges and a further improvement from the adoption of the copper lead liners.”

In a previous 1934 report on bearings Sparrow also noted that at the high speeds he was testing (4500 rpm) cracks would appear first at angles of about 45 degrees off center in the cap that corresponded with the point where the load on the rod switched from tension to compression (gas load on the piston versus the centrifugal force in the opposite direction due to the inertia of piston and rod). He theorized that at high speed this is where the oil film might break down as the rod shifts slightly with the change in direction (SAE 34009).

The rods you show above look like a failure initiated near or at the side flanges at top dead center which corresponds with where the oil film would be most likely to break down under conditions of low rpm and high throttle when the gas pressure would be near maximum pushing down the rod with little inertia force acting opposite. This would be from low speed lugging.

I am sure that there are definite thermal expansion issues with thick babbitt. That would probably manifest as fatigue cracking added to the cyclic fatigue of the reciprocating loads. The thermal expansion would primarily be a function of hot and cold cycles (cold start/run/shutdown cycles).

Babbitt – like concrete – apparently always develops cracks. One of Sparrows comments on a set of his tests (he undercut portions of the babbitt surface to extend life) was “The cracks are slightly more numerous in the bearings with the undercut edges, but the undercut portion has served to as a barrier to prevent the cracks from spreading and permitting the babbitt to escape. As a result, although these bearings are marked by lines of ‘worry and care’ they are still serviceable”.

Jim

An additional thought on the pictures of Greg’s rods. Thick babbitt does not have high fatigue strength particularly at high temperature. It could be that the failure did not need to be from a complete breakdown of the oil film, but simply fatigue from the high stresses in the babbitt from the high gas load of the piston.

Jim

CannonBall Baker, the over-the-road race driver in the 1920’s, contracted to Franklin for a time in attempt to set new coast-to-coast speed records. His first try was in 1927 with a Series 11 Franklin. The engine failed at Indianapolis.

The Series 11 Franklin had thick Babbitt bearings, as most did, but also a non-balanced crankshaft. No attempt at balancing, just plain crank throws off the mains. Even though it was a seven main bearing six and the bearings were pretty wide and beefy, at high speeds the Babbitt got “pounded out” to the extend that oil pressure was lost on connecting rod 3 or 4, which resulted in a thrown rod.

CannonBall tried again in 1928 with the Series 12 which had a counterbalanced crankshaft, and made it to California with no troubles and set a new record.

The point is as Jim mentioned, Babbitt has low fatigue strength and even without Babbitt-to-crankshaft contact, will deform under the pressure of combustion. And in this case, the pressure of a crankshaft journal that does not want to run perfectly smooth axially, even though the main bearings tried to hold it in one place.

So even new thick Babbitt will experience plastic flow, has low fatigue strength and, apparently, can develop cracks which may or may not effect integrity.

And as Greg pointed out, even if it doesn’t necessarily delaminate from the steel, old Babbitt bearings do tend to fall apart with age. I suspected my Packard was not unique, so it’s good to hear this same failure mechanism is common.

I wondered why, when the option of automatic transmissions appeared, it was not unusual for the engine in the automatic-equipped car to be rated a little higher in HP. I concluded that perhaps it was desirable to have a little more output to compensate for the effect of the automatic, and this was possible because the firing pressure could be increased without compromising engine life due to the fact there would be no lugging possible with an automatic.

We operate many old, large-bore gas engine-compressor units, which are equipped with relatively thick Babbitted bearings. Our experience is that thick Babbitt has less fatigue life and will crack and flake out. Bonding when the Babbitt is poured is also critical. Newer machines with higher speeds and firing pressures went toward thinner Babbitt, and even solid aluminum bearings. The latest higher-speed engines are equipped with steel-backed trimetal bearings with almost no Babbitt. They have to be just about perfect but will run very reliably. They wreck fast and hard, though.

Very interesting discussion. I had my 1930 straight 8 rebuilt at a shop that specializes in rebuilds and was surprised that the oil pressure runs high 50 psi all the time. The car and motor were in a bunch of pieces “basket case”” when I started to put it together. The wear on the motor was minimal but I thought it would be a good idea to have it assembled by folks that work on motors routinely. The engine has about 4 hours run time total over two summers and the engine sounds very very good. I have changed the oil and have not found any thing that looks concerning. I have used Valvoline racing oil 10W30. I have backed the spring out as far as I think I can go and have tried a different oil pressure gage. Does any one have any thoughts or comments on if this is a problem or anything else I might try? Is this because the clearances are still tight?”

David, it does seem a bit puzzling. Does it maintain 50 psi even with the engine warmed up at idle?

What I would like to separate here is the damage and wear caused by the actual operation of the engine, a corrosion process from being exposed to water or acids over time, or babbitt protected from the elements actually has some process that causes the characteristics of the metal to change from some internal process independent of external factors.

If one sees damage that has to be fixed it is a moot point. In my case, the picture of the cast babbitt flange is from my 845. It was rebabbitted in the 1960’s and run for a few hours then parked again until I went through it and started running it recently. My bearings all looked very good, but I have no way of knowing if the 1960’s rebabbitt job was good. Likewise if I were to get them rebabbitted now “just because”, I don’t have any reason to believe the new babbitt would be applied better than it was in the 1960’s when it was a more common practice.

In general I give the original factory the benefit of the doubt and only replace or repair if necessary.They had the processes and tooling established in a systematic way that a latter day restorer does not have – me in particular. I always ask the question of whether my or a professional shops repair work is going to be actually better than the original with some wear.

Jim

I think there are several Babbitt shops today who know how to do a good job. Perhaps a better job than in the old days if only because we have such an improved understanding of the metallurgy involved than we did 50 years ago. As someone pointed out earlier, these were just used cars back then, and perhaps whoever did your rebabbitting in 1960 didn’t have quality in mind.

My concern with constant high oil pressure is that you may be wearing something out in the oil pump. ??

I am on board with Greg and others that if it’s ain’t broke, don’t fix it. If the car runs well, sometimes it’s best to leave it alone. BUT I am hugely in favor of at least checking things, as this discussion on broken Babbitt all-too soberly illustrates.

Concerning motor oil, I do agree that especially on a newly rebuilt engine 10W-30 may be the better choice, even though I am running 10W-40. One aspect of oil I do support is the use of an oil with high affinity. Meaning, the ability of the oil to cling to metal components during long storage periods. That way when you start the engine after sitting for three, six or nine months or even years, there is something there to separate the metal parts.

At the moment I’m using “Driven Racing Oil”. The company makes a 10W-30 and 10W-40 oil which, uncomplimentary called “Hot Rod Oil”, are designed for vintage and other vehicles that aren’t used much. It’s a mil-spec formulation because in the military, just like our old cars, sometimes vehicles do sit for prolonged periods of time but need to be good-to-go when needed.

Thank you all for an interesting, logical discussion

This is an “UBA” – Unsupported Broad Assertion – but I would question whether improved understanding of metallurgy has been applied to babbitt and small obsolete engine rebuilding shops since WWII. The technical attention was shifted to more advanced materials – copper lead was old hat by WWII with exotics like silver-indium coming into play on aircraft engines. I believe it mainly boils down to quality control and processing that was very well understood by the manufacturers who were doing thousands per day with qc, research and test departments to back them up. I would bet a lot more has been forgotten than has been learned.

If I had to get new con rod bearings I would probably find a way to convert to a later copper lead insert, with the complication of having to figure out how to replace the side flange material. I know it has been done on Pierce-Arrows. Side flange clearance is important for limiting oil flow out of the con rod and overwhelming the oil control of the piston rings.

My skepticism comes generally from my aircraft engineering career where you might be amazed how much past technology is unknown and dismissed. In spite of their incredible performance and reliability, aircraft and engines are designed today making basic mistakes that were learned in the 1940’s. Actually, much of my career was spent trying to get engineers out of their complex computer programs and look at basics and what was done before. Often I would be in meetings where some feature was dismissed as unworkable and I would say – “but you guys did it 50 years ago”. Of course “those guys” were long gone from the company. Apologies for the soap box!

Jim the oil pressure is 50 psi when the engine is cold or warm at idle. Seems to start and run very well.

Dave

How do fork and blade engines get away with the surfaces that they used for

bearings and how do they rebuild them? Did they wear out faster than standard

bearing cars. Lincoln was noted for quality. Why did they choose to go with

fork and blade?

Tony, in the paper I have been referring to Sparrow cut down the surface area of his bearings in half and improved their life at 4500 rpm. There is more than enough surface area at higher speed, maybe not so much at idle speed. At speed the large bearing surface area just adds a lot of heat and friction.

Blade and fork designs allow the cylinders of each bank of a V engine to be in the same line instead of offset by the width of the connecting rod. On a V-8 such as early Lincolns, this would have prevented a rocking couple slight imbalance unless counterweights were added to the crankshaft. It is theoretically a more elegant design, albeit less practical for an auto engine.

There are two ways to do the fork and blade, I am not familiar with how Lincoln did it. The first is to have two narrower bearings for the forks and a wider bearing for the blade. The bearings and crankpin can end up having the same total area as if they were offset with two con rods bearings of equal width. The narrower bearings actually tend to have fewer problems than wide bearings. The Rolls Royce Merlin used on Spitfires and Mustangs used this approach, and I imagine was what Lincoln did.

The Allison V-12 used on P-38, P-39, P-40 and the last P-82 Twin Mustangs had a single bearing for both. The bearing was fixed to the forked rods in the conventional way, while the blade oscillated on the outer diameter of the bearing bushing similar to how the articulated rods attach to the master rod of a radial engine. This arrangement allowed for a smaller total bearing area needed and a reduction in weight. Some air race engine rebuilders retrofitted Allison rods into Merlins because they were stronger.

Jim

I replaced rod Babbitt with inserts on two car, my ’31 Pierce and my ’38 Packard Super 8.

The Pierce rods were sent to a shop in California, with the sides built up to “replace” the side flanges. Worked perfectly.

When we did my Packard, I could find no one who would build up the side flanges, so we decided to braze three “dots” on each side of each rod, and machine to proper clearance. There is no side thrust so brazing was considered fine, and then inserts were fitted. There is NO loss of oil pressure due to not having side flanges. This solution has worked fine.

As a side note, comparing early aircraft engines is a tough comparison to a car engine. For example, the OX-5 engines that powered Jennys were extremely complex, with literally hundreds of parts, the failure of ANY ONE would cause engine to fail. That said, the average life of a Jenny airplane was measured in hours, or generously, tens of hours, on the warfront, so an engine only had to be “reliable” for a short time. I’ve worked side by side with a friend as he rebuilt an OX-5, they are scary complicated and fragile….

The only problem with inert is the person doing the work. It’s much easier said than done. John Cislak does them for eights and twelves, my self, I run babbit, and I run my cars hard and many more miles than most. My current twelve has 20k on babbit, and the oil pressure has stayed steady since day one. On a Pierce, be more concerned with cam bearings.