- Home

- About Us

- Join/Renew

- Member Benefits

- Member Pages

- Log In

- Help

- Museum Store

Gee, the ’29 looked great at Lexington and we were very happy about it. Except for that little regular chuff out the exhaust pipe that I heard on the show field.

We got home just fine with none of the vapor lock issues we had on the way down. So I decided to run a compression check to see what was up and number seven cylinder came in at 37 lbs. It had plenty of valve clearance so I figured I’d better pull the head to fix the valve.

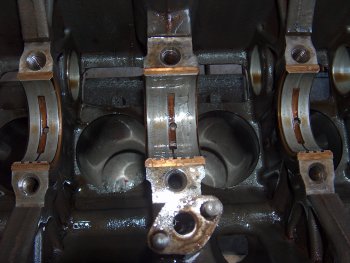

I pulled the head and found that the exhaust valve had not burned but the block was cracked from the seat to the cylinder. That meant that the cylinder would need to be sleeved and the engine would have to come out to be fixed. Well, okay.

I pulled the rods as part of the disassembly and number six rod bearing disintegrated when I pulled the cap. Three other rod caps showed fractures that had not yet separated. I have about 10000 miles on these rods. Things are piling up.

I next removed the crank to complete the disassembly and found that the center main bearing was also crumbling. These mains are original to this engine and were fine when we put it together. Did I mention that the crank journals were also pitted? Enough, already!

Wilma and I both feel lucky that we made it home on our own power. So, now what?

We have two other ’29 blocks that we’ll be scrutinizing to see which will be the least expensive to bring back to new. We’ll keep you posted. Incidentally, we’ve been running a 3.54 rear end gear since just before the Boerne meet in 2000, so there are no guarantees with old parts.

For grins I’ve enclosed a photo of the block.

Ain’t old cars fun?

Bill

Somewhere in the old Pierce Arrow shop notes (factory) I remember reading that they recommended grinding the valves every 20 to 25 thousand miles, changing the head gasket (of course), and flushing the radiator every year. In those days it was probably unlikely to travel more than 5000 miles a year, and at speeds of less than 50 MPH. I travel 25 to 35 thousand miles per year and find that only a little abnormal. So with 100,000 miles on the car it is like 20 years of its life! These are good engines, and I’m surprised at the crack in the block. It got overheated somewhere along the line and destroyed itself. If you have to rebore the engine, consider doing all cylinders to maintain equal balance, and slightly over bore, mill the block and the head and raise you compresion ratio to 6.5.

Bill: During the forty years I have owned ny 1936 1601, I had the rod bearings repoured once, and had one rod burn out in Florida subsequently, and had it redone. When I gave the car to John Ciselak three years ago for a complete engine overhaul, the bearings were all crumbled again. I have come to the conclusion that most of the people doing babbit bearings today: 1. Don’t know what they are doing,or 2. The proper material to make babbit is not available to them. Tony

Many babbit guys will recycle old babbit into the new, and you end up with a unknown ratio of tin and lead. There is also a “high pressure” babbit available out of England that they run up to 8.5 to 1 on the blower Bentleys’’ that holds up well. I learned how to pour babbit from a Springfield Rolls engineer in the 80’s. His big push was that almost nobody correctly tins the shells before they pour it. He said that is what leads to bearing delaminating. I suspect the problem is two fold, used/poor grade babbit and also poor tinning. Add to that the higher rpm’s we run our engines today along with the tall gears that put way more of a load on the engine at lower rpm’s causing lugging much more often than when new. My 36 twelve has babbit in it, we now have 12k miles on the babbit and so far have had no problems, and I drive it vary hard. At the PAS meet in June John Cislak had a flyer on converting rods from babbit on all the Pierce engines. 29-33 eights require welding on the rod, later eights and all twelve’s can be converted on his fixture to inserts, and you can order the bearing size to the spec of your crank. As for the pitting I have also suffered from the problem both in the crankshaft, and cam as well as the transmission. It can only be caused by two things, water or acid in the oil. Most problems I have seen seem to be from very old oil that was left in for years at a time. I highly recommend that ALL fluids be changed every two years regardless of mileage. As far as the engine block cracking, there seems to be quite a few eights having this problem over the last few years. I would probably stitch it to keep the block original, and just freshen up the engine with rings and a valve job.

More details.

The rod bearings are failing in the CAP only, which is the “unloaded” side. Therefore, lugging would not seem to be an issue. Because we drive this one a lot, I can’t really blame old oil either. The center main bearing also fractured on the upper (unloaded) side. The cap, in this case looks okay. I’ve looked at two other sets of main inserts and the upper center bearing in each shows some fracturing while all other main inserts look okay. With the rod on either side in the same plane, I can understand why there could be some whipping of the crank.

Bill

Inretesting that the failure is only on the rod caps. Last time I saw babbit priced out the mains were between 125 and 150 a bearing roughed out. Rods were 125 cut to size each. You get to two thousand real quick and still have to align bore the mains. Did the babit pull away from the shells/caps or crumble and still leave babbit in place?

Ed,

The babbit had fractures and broke away in the center of the main bearing, but all pieces were still encapsulated because the outer edge had not failed yet.

On the rod bearing a piece of the cheek broke away and I found it up in the valve galley sitting on the block. The rest of the pieces were still in the bearing but fell away when I removed the cap.

About 25% of the cap had failed and three other rods showed fractures in the caps but no breakage. I could hear the hint of a rod knock over the entire trip when I was driving at 50 with the throttle open enough to maintain speed. If I either sped up or slowed down the sound went away.

The babbit in the caps was dark grey while the rod side was much brighter. The car sat a lot over the past two years and I’m wondering if that was a factor.

Food for thought.

Bill

I wonder if they poured the caps with a diffrent batch of babbit than the rods? I hve only seen OLD babbit fail, it was all over 50 years old. Have you figured out your game plan among the three engines?

Well, it’s Spring so it must be time to put things back together. The block is all stitched up with two new valve seats and a new sleeve in number seven. I had much fussing with the new main bearing as it was a little tight when I torqued the cap and I wound up doing some careful sanding with 1000g paper. Takes a long time to remove any material with that so my chances of overdoing it were very slim. It’s now just fine.

Block comes home next Saturday and will get the transmission bolted up and back in the chassis all at the same time. We’ll be driving it to Gilmore to put it in the PAS Museum and bring the ’31 home. Times a’wastin!

Bill

Don’t forget to put harden seats in ALL exhaust valves.

Bill,

I would think long and hard about continuing to use solid stainless exhaust valves.

Greg

Thanks, Leo.

Greg,

The exhaust valves are old originals. Only the intakes are stainless. I gave up on stainless exhaust valves in 1999 which was the last time I took the engine apart.

Bill

Have the old orignal valves refaced with Stellite rod and turned and ground to correct angle, works very well.- Leo

Leo,

Do you know the name of a shop that can reface valves with Stellite? I’ve never had it done and would like to investigate. I’ll also ask my local shop if they know of a source.

Thanks,

Bill

I had it done at Warren Industrial Welding in Clinton township Mi. They are now closed. Any good welding shop that repairs tools and fixtures should be able to handle the job.I watched the welder do it. Put the valve stem in a V-block and turned the valve slowly while building up the valve face with Stellite rod using a Tig welder.He charged $10 each. this was about 5 yrs. ago.–Leo

know an opinion is like a sphincter……every body has one…. but as far as stainless valves go I wouldn’t use any thing else. #1 All modern diesel engines use stainless valves and have no problems, #2 The top fuel dragster we (John Cislak and Ed Minnie(crew).) RUNS IN THE SIXES” and we have no problem with them, #3 The vintage racing team of both Bentley and Stutz that we work on and help out also use stainless valves. Stainless takes the heat much better than steel, the only downside is stainless is not as hard, but it is also much easier to cut valves than keep cutting the block and lowering the seats. I also would NEVER run hard seats. They tend to fall out and cause problems if put in crooked. The cars didn’t have lead in the gas till the late 30’s. Our Pierce cars can run fine on unleaded gas and stock valve seats. Just my 2 cents.  Ed

Ed

Ed,

I totally agree with your comments on the seats and problems with seats falling out.

My comment about stainless was directed at the process of just hogging a valve out of a chunk of 304 or 316 SS bar stock. The ones I’ve seen sold “for Pierce” were just that.

Regarding your comment about Diesel engines- the alloys are not simple stainless grades, the valves are generally sodium filled for cooling of the heads and the stem’s are generally welded to the heads. I dont doubt that a high quality valve constructed via typical automotive/industrial processes will work fine in a Pierce. The thermal conductivity of stainless is much poorer than conventional steel alloys, so they will naturally run hotter.

Greg

Bill

I have successfully used a product called “Timesaver” lapping compound for tight bearings.

It is used to lap in plain Babbitt bearings. The powder comes in different grades of fineness. Mixed with oil it forms a paste that is placed in a bearing and then the shaft or crank is rotated. The fine grit breaks down in a few minutes of use and needs to be replenished if the bearing clearance is not enough. If one Googles “Time Saver Lapping” many sources come up.

When I rebuilt my ’29 I used intake and exhaust valves from John Deere and IHC farm tractors. I found them by searching valves by size on the Sealed Power web site. The valves used in modern farm tractors are superior to anything that was made 80 years ago. I found valves that had slightly larger heads so that I could grind the seats a little larger and clean up all of the pitting that was evident. That way the valve sits up higher, more like when the engine was new.

Anyway, my 2 cents worth.

Cal