- Home

- About Us

- Join/Renew

- Member Benefits

- Member Pages

- Log In

- Help

- Museum Store

Recently we were able to get our 1930 Model B straight 8 on the road for a number of runs now totaling 45 miles. The steering is a bit stiff but improving and the brakes could be a bit tighter but it ran very well on all the short trips (and in my shop too). All was well until the oil filter housing split. Luckily I had the battery door out when I was on the road with the car and saw the oil coming out, shut it off and towed it home. I put a spare Purolator filter that was from the pile of parts and added a calibrated glycerin filled pressure gage to look at the pressure more closely. The idle oil pressure is about 90 psig and when the speed is increased its over 200 psig. I adjusted the pressure relief but no real difference either all the way out or all the way in. I tried taking the spring out and no difference with that either. I understand from the bulletins that the pressure can be 40-50psig at high rpm and as low as 2 psig. The engine temperature was good the whole time and the engine still sounds smooth. The last trips with the car the ambient temps were in the eighties. The engine shop says the warranty is not valid as it was cleaned and completely rebuilt in 2015. (too much time has passed). I am not real sure where to start. I suspect that something is blocking the oil flow and the pump is dead heading. Has anyone ever had this happen to them? What are the best places to check? Can I do any testing to narrow down the search?

Any advice is greatly appreciated.

Dave

Did you check that the oil pressure regulator piston wasn’t stuck closed so it doesn’t allow any oil to bypass? I’ve had a pressure regulator on a brand X stuck on a burr the other way with 0 oil pressure.

Hello Jim, Thank you for your reply. I was wondering about the pressure relief piston too. I took the cap and spring off but I am not sure how to move the piston in and out to see if it is stuck. The piston is below the frame rail. If you have any thoughts on getting to the piston I would appreciate them.

Dave

David:

Great looking B you’ve got there.

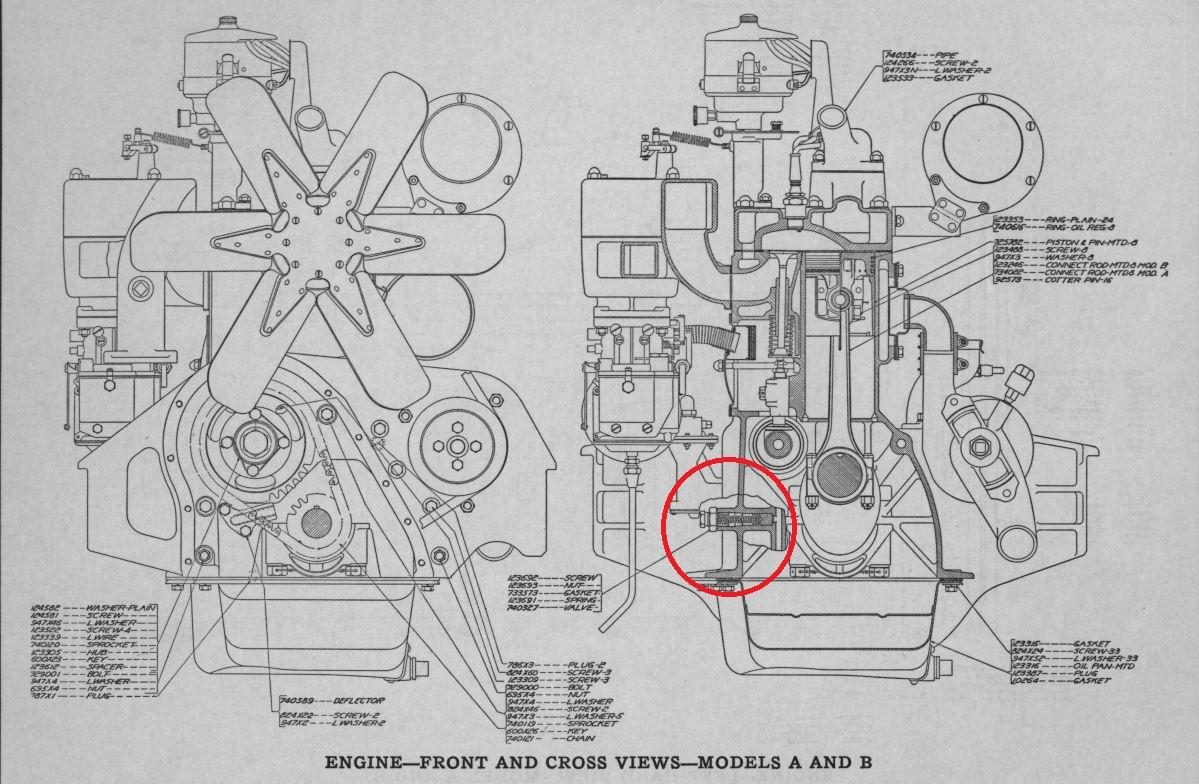

One of the members was kind enough to forward me a copy of the ’30 Pierce parts catalog, covering models A, B, and C. I’ve highlighted the pressure adjustment in red. Maybe this vantage point will help…

There really isn’t anything mentioned in the Service Bulletins about adjustments that I could find.

I’m not sure how to interpret the detail in the circle, presumably the oil gallery fed by the oil pump is the channel at the right perhaps rotated at 90 degrees for illustration purposes, i.e I imagine it is a horizontal channel cast in the block. At any rate the problem could be the piston is stuck in the closed position as shown in the illustration without access to push on the front side. It would be difficult to pull out to see if it is free or stuck. Perhaps someone has a dissasembled a piston and could take a picture to see if there is some way to get a hold of the backside of the piston with nuts and springs removed to try and pull out.

If it is stuck perhaps a generous soak sprayed into the back side with rust cutting penetrating oils such as Kroil could loosen it. Perhaps additives in the oil such as Rislone, seafoam etc to work on the deposits from the oil side and temporarily use a light vicosity oil to reduce the excess pressure when running, just start it and run briefly at idle once a day to work the oil in. With 90+psi pushing it would probably come loose very suddenly, if that is the problem of course.

Hard to know what variables are at play, here, but had hoped the schematic/cross-section would offer clarity about the pressure relief valve and its components.

Can you disconnect the oil gauge line at the elbow/block (driver’s side, near the oil fill) and pressurize the gallery with air? Maybe there is some residue, though I presume the shop cleaned all the galleries thoroughly during the rebuild?

Also, what oil is in the crankcase? Detergent or non-detergent? Just wondering if some residue could’ve broken free.

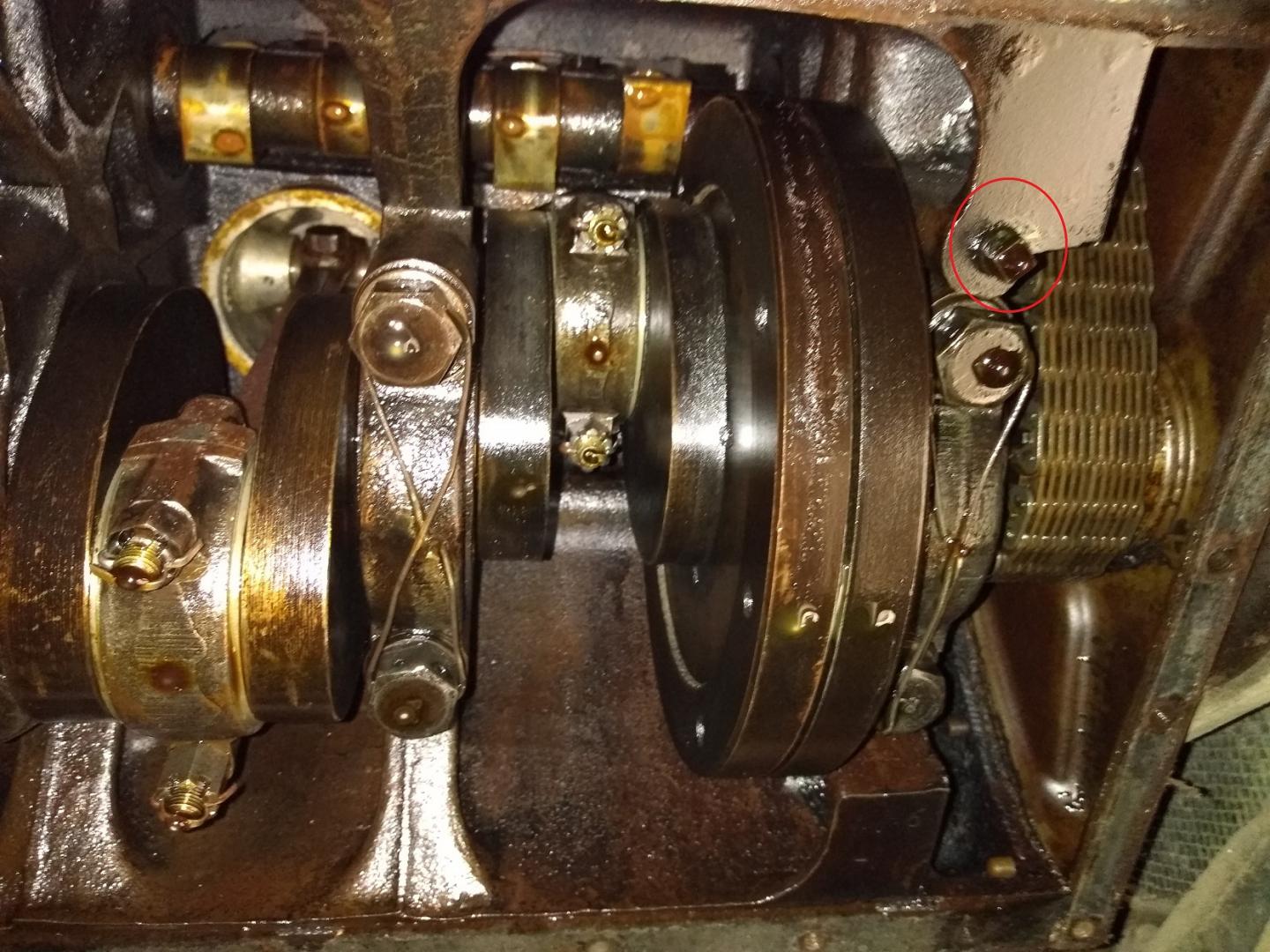

I believe there is also access to that pressure relief/gallery by removing the oil pan and locating a smaller pipe plug on the bottom of the block (assuming you need to go this far). I’ve included a photo of my Model B when I cleaned the oil pan and inspected the rotating assembly.

Jim’s suggestion about Kroil is on the mark. I’ve had good luck with it for machining and marine applications. Have also had very good luck with Ferrosol by Bilt-Hamber for stuck Mercedes mechanical injectors, among other things. I favor it:

https://clean-garage.com/bilt-hamber-ferrosol-500ml-multi-purpose-aerosol-lubricant/

Thank you for your input. Today I disassembled the pressure relief/regulator. It came apart as it should and the piston slid out easily with the assistance of small magnet. There were no burs or particulates found. The oil is new Valvoline Racing oil 20W50 with Zinc. I also ran the engine with out the piston and spring in. The pressure remained at zero. I used a gage that goes to 500 psi. I put relief back together and found that the oil pressure is still very hi 100 psi at idle and almost 300 revved up. The pump is dead heading. I plan on next removing the oil lines and using air pressure to see where the blockage might be. My guess is that the shop that rebuilt the engine put something together incorrectly. Could it be a part was wrong as this car was a complete basket case and a part from say a Model C was mixed in the pile. The shop did rebuild Pierce engines and other vintage motors and they say they still do. They are now under new ownership though. Im not comfortable bringing it back to them as I may get similar results. Any thoughts are as always greatly appreciated. BTW using a fiber optic camera I could see that the relief hole back to the oil pan is at about 5 o’clock when looking at the pressure relief. The inlet to the pressure relief is as shown in the parts manual.

Dave

Thanks for the info., Dave.

Have you consulted with a machinist that deals with Pierce engines day-in-out like John Cislak?

Aside from pressurizing any debris/blockage out of the galleries, my concern is the oil clearance for the main bearings. I wonder if these bearings are too tight?

If you have concerns about the quality of the overhaul, it would be worth draining the oil/inspecting and removing the pan to get a better look at the bottom end.

Good that you found the piston is free. I am unclear though, before it still had high oil pressure with piston in but the spring removed? Now it goes to zero pressure with spring and piston removed, indicating the bypass is clear without the piston. Not sure how to interpret that. Will it still read high if you put the piston back in but leave the spring out?

I assume both the pressure relief valve and port reading the pressure is downstream of the oil pump fed by the same oil gallery system that feeds the bearings, so I don’t think the pump would be deadheading.

I echo Carl’s concern that the bearings might be set up too tight. Extreme tight clearances make for a quiet engine until the bearings fail. 20W50 oil is thick and contributing to the high oil pressure, although probably not a primary cause. My 35 manual recommends nothing thicker than 30 straight weight, Packard recommended 40 only if average temperature exceeded 90F. These engines were designed to use thinner oils hence the large bearing and piston surface areas. 20W50 provides greater load capability that isnt needed but increases bearing temperatures, not good for babbit. Multi vis is good, but I would use 10W30 or at most 10W40. 10W30 is thicker than 30 straight weight at temperatures above 210 F that the local bearing temperatures will see.

Thanks Jim and Carl,

The oil used is what John Cislak had recommended a number of years ago. He liked it because it has zinc. (Valoline racing 20W50 high zinc)

The oil pressure was high with the piston and spring in regardless of if it was adjusted all the way in or out.

The pressure was zero with the piston and the spring removed. Makes me wonder if the piston is so long that the relief port is covered.

I plan on taking the piston out and measuring it and I will give John a call to see if its the correct one.

The spring I did purchase from John so I am comfortable that its the correct one.

I will keep you posted.

Dave

You can get zinc additive and not have to resort to such thick oil. Ab Jenkins was using 20 straight weight on his speed runs in the hot desert of Bonneville. 20 straight is a fair bit thinner than 10W30 at high temperatures. At low temperatures the viscosity for any of them is dramatically thicker than needed to maintain oil film thickness.

Rather than guess at what parts are correct or not you could just stick something down the port with everything removed and measure how deep it is to hit the ledge that the piston head sits against. A long bolt or threaded rod a little smaller in diameter than the piston with a nut at one end could be used to bottom the bolt in the hole, then turn the nut until it touches the end where the regulator nuts bear against the outside of the block. That gives you total depth. Then measure the length of the piston and everything except the spring that goes into the hole with adjustment screw all the way out to see if the piston has room to move out without the spring. A wire with a very short hook bent 90 fegrees at the end could be used to find the depth of the start of the bypass slot. This would determine if something is too long to let the piston open enough.

Assuming there is then the spring might be too stiff or too long. With the measurements of the hole and pieces including some spring dimensions I could calculate.

Hi Jim and Carl,

I am feeling a lot better about the oil pressure. I ended up making a lighter spring work that I had from a spring assortment. The idle pressure is now 22 psig and the revved up pressure is 40 psig. The engine is running very smoothly!!! I will keep an eye on the pressure though using a temporary gage. Thank you for your help I really appreciate it. Please see the spring comparison. I also installed the spot light.

Take care,

Dave

Thanks for the update, Dave. Good to see “the fix is in” and that your oil pressure is closer to where it ought to be.

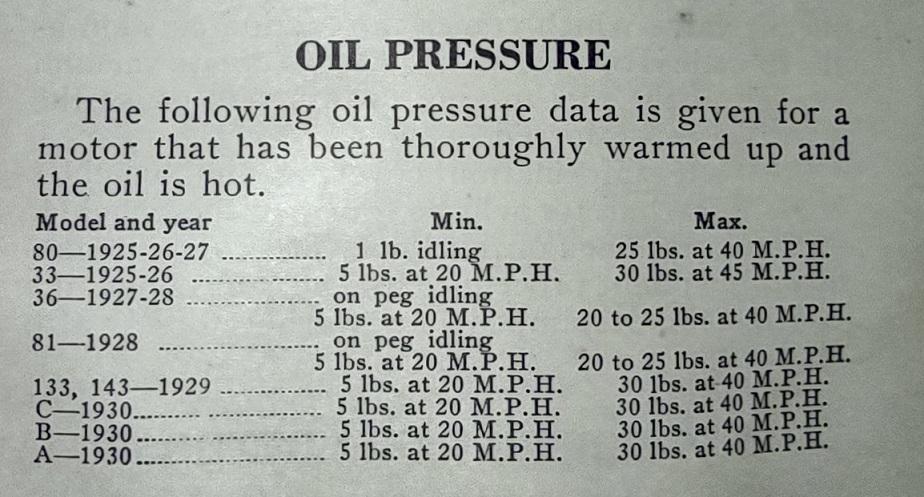

Here’s an excerpt from the 1930 RADCO Carburetor and Motor Tune-Up Manual with the oil pressure values for 1925-1930 Pierce-Arrow models:

Just a guess, but your old spring appears similar to the one I found in my 1936 8-cyl that was far too strong once I had the rods rebabbitted. So I speculate that some previous owner or mechanic installed a much heavier spring in your engine to compensate for extremely loose bearings. With a rebuilt engine or new bearings, a much lighter spring is needed.

Later blocks are more difficult because one has to drop the pan to gain access to the spring. On my 1936, the first spring was too light, but I’d only put four bolts in the pan and six quarts of oil. The second spring was the charm–a good thing because I had three others of different tensions as possibilities.