- Home

- About Us

- Join/Renew

- Member Benefits

- Member Pages

- Log In

- Help

- Museum Store

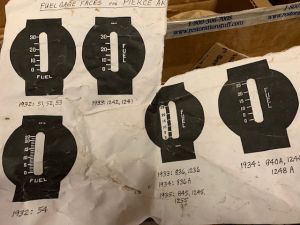

Please look at the attached picture and ignore the temp gauge in the center of the picture. Are either one of the faces on the left and right for the 1933 model 1236 V12 Pierce Arrow?

The face plate on the right is what is in my 1934 and 1935. May not be correct for ’33–I’m sure it would be so close, no one would notice.

Bob

The center temperature gauge face and the right fuel gauge match for a 1933 836 or 1236. The background is black with white letters that identify FUEL. On the opposite side of the opening for the glass tube is a vertical “capsule shaped” white patch that has black numbers that identify the quantity 0,5,10,15,20,25 gallons. Heavier black lines extend to the opening @ 5 (gal) intervals and on some gauges there are 4 thinner lines between the major lines. The 1934 fuel gauge has a black background with white letters to identify FUEL on the right of the opening and on the left white numbers with tick marks to the right of the numbers 0,5,10,15,20,25. Within the instrument panel the FUEL gauge was on the left side. Lange’s gauge is from a 1934 but have not deducted from a judged event.

Bill,

Here is a picture of a 1236 dash if that helps. Looks like the left one.

Here is a close up of the fuel gauge on my 1933 1236 EDL:

This appears to be identical to my ’35 845. I generated a CAD model of the facia markings for restoration if it would be of any help.

Jim

Thanks for the help guys! It wouldn’t hurt to look at the cad model Jim. We might be able to use it to create a decal or something along those lines.

Bill Edrich

Jim,

That fuel gauge looks like it is a hydrostatic type.

Is that correct, and if so, do they work better than my King-Seeley, which is not really functional?

Peter

This pic appears to support all the excellent feedback in this string.

Bill, the CAD files are on their way.

Peter, mine is the King-Seeley hydrostatic gauge. The previous picture shows the test I did to see if it would work off the car first. The two big problems as you know are getting the connections of the tube between the gauge and the sending unit as perfectly sealed as possible. On my test I immersed the sending unit in a jerry can of fuel and timed how long the column would stay up before leaking down. I got it to where it could last more than a week. I think some have soldered the connections or used sealant when making the connections, I didn’t want to do anything permanent for my test since I had to take it apart again to install on the car.

To keep it working on the car it must be driven periodically to slosh the fuel around. The whole complicated sending unit in the tank relies on the fuel sloshing around to fill the little trays that then drain down with trapped air down the tiny tubes and replenish the air trapped in the top of the can at the bottom of the unit. I don’t think the air gets recharged with a full tank or nearly empty tank so I theorize that 1/4 to 3/4 tank is probably best to keep it working. Of course if the tiny tubes get plugged with junk they won’t work either. This requires either a pristine tank with no sediment or a filter around the sending unit. I built a filter to surround the sending unit but won’t know if the whole mess works until I get the car on the road. I don’t think my filter turned out to be a very good design, it became a real kluge to get it to go down the fuel tank hole. With a couple years to mull it over I am thinking of redoing it. Instead of surrounding the entire sending unit assembly with a brass mesh, I am considering applying a fine mesh to the tops of the little trays themselves and a separate filter for the main fuel pick-up tube. It probably also needs a screen for the bottom of the can since it has a very tiny hole that lets the air bubbles get into the can. Mine was blocked with old gas sludge.

It is with some trepidation that I post the picture of my kluge. In my mind it didn’t start out this crude.

Jim

It occurs to me that perhaps it would be possible to get a KS fuel gauge working again that has stopped because it has lost its air charge from a miniscule leak after sitting for awhile.

Install a stop valve somewhere between the sending unit and the gauge and close it. Install a tee connection to the line between the sending unit and the new stop valve. The line coming from the tee will also need a stop valve. Blow air into the tee to clear the line and sending unit of fuel – might be able to hear it bubbling in the tank when it clears. Close the valve going into the tee while still blowing air into it. Then open the valve going to the gauge.

Of course the valves and their connections introduce a new source of potential leaks and could make the problem more frequent.

Jim

The KS fuel gauge in my car was registering gas when I first got the car, but stopped working the following spring after sitting all winter. Is there a chance, that driving the car around with 1/2 to 3/4 tank of gas, it might start working again?

Ken and James,

I overhauled / replaced the K-S system in entirety and it still doesn’t work properly.

Tony Zappone once suggested to me a novel and foolproof solution to the infernal K-S fuel gauge problem.

He told me the he took a piece of the RED TUBING that comes with WD-40, cut it to size and dropped it into the open top of the Fuel Gauge Sight Tube.

His fuel is now always three-quarters full and he just gasses up before any major drive or tour day.

Essentially, I do the same, that I gas up a bit, or a lot, before going off for the day.

At PAS Meets, I admonish new members to Fill-UP every morning before a tour.

One Gent who I specifically urged to do so, and who was later fuel-less on the side of the road, explained to me that he “did not intend to run out of gas.”

Ken, one needs to have the gas tank filled before topping off the liquid in the K-S system. That creates a “baseline” for the hydrostatic system.

I would suppose that you need to FILL-UP before you can determine if the gauge will again work correctly.

However, sometimes you just need to add more of the red liquid, which by the way, is UV sensitive, so if exposed to too much sun, the red liquid turns clear.

Peter

Jasmes,

I didn’t see your big post before I responded above.

My K-S only has the assembly on the right and both the original that came with the car (installed in the 1930s?) and a replacement failed to give the results I sought.

I was not excessively compulsive about the repair / installation, etc., so I probably could have gotten it to work, but instead, I just fill up.

Pebble Beach is not a goal for Chauncey.

Chris Diekman did a nice writeup on the K-S a few years back. Perhaps here?

Peter

Ken, I am hoping others with more experience will post, since at this point I don’t have operational experience. I suspect that once the trapped air leaks out of the top of the lower can and floods the sending unit tube up to the level of gas in the tank that it would likely take a lot of driving before enough air is restored to get it working again, or even not start working even with a lot of driving if the surface tension of the fuel in the sending unit line prevents the air bubbles from rising in the small tube and purging the fuel.

There have been of course lots of PASB articles and posts on this problem through the years.

Like “Chauncey” I have no trophy aspirations for my Pierce, but enjoy the challenge of making stuff work again. We know they must have worked to a reasonably acceptable level when new, and maybe it was simply that they would have been driven regularly, had no varnish or sediments in the tank and had never been disassembled. My idea above of adding valves to the system to provide a means to back flow the fuel out of the sending unit will probably create more problems than it solves unless a dead certain seal in the valves and their connections can be achieved – I will be cogitating on that.

I did an experiment a few years ago trying to determine how fast the K-S fluid would lose its color and if the fluid from different vendors lasted longer. I purchased new K-S fluid samples and put them in glass dropper tubes and set them directly in the Nevada sun for the summer. Some had UV protective glass in front of them. None of them had turned color by the end of the summer, and to date still haven’t turned sitting around in my garage.

Oddly, however, the fluid I had in my gauge for the test of my system shown in the picture above was bright red for test but after a couple of months in the garage without direct sunlight it suddenly turned light amber in the space of a week or two. That fluid was one I had bought over 20 years before and had been kept in its black light blocking packaging the entire time until put in the gauge for the test.

I think it is a combination of age and light, not just the light exposure alone.

Jim