- Home

- About Us

- Join/Renew

- Member Benefits

- Member Pages

- Log In

- Help

- Museum Store

Tagged: engine crank, Extension, ratchet, tool

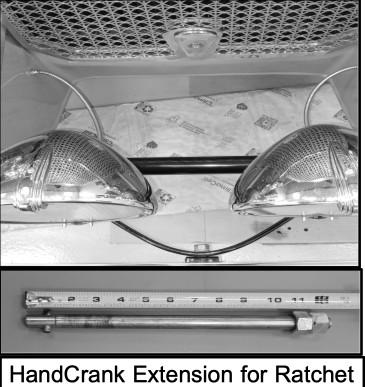

After yet another session (the laying on of wrenches) with the distributor while turning the engine with the hand crank, we decided there has to be a better way. My car has Trippe lights on the front bar and the cables are in the way using the standard crank. Also, a previous owner had ground the old crank nose into a “screwdriver” and would no longer work as intended.

Being both inventive and cheap, my buddy came up with a tool that fits into the crankshaft dogs and extends about half way between the stone guard and the cross bar. The tool was made from a piece of steel rod about 12 inches long. The engagement pins are a standard roll pin set to the same distance from the end as the ears on the original crank handle. The crank end of the extension had to be turned down a bit after the first try to fit the crank pilot hole and the other end was threaded. The jam nut method works, but is probably not the best way to fit the 12 point socket. I recommend permanently attaching the nut to the shaft with either a puddle weld or brazing.

The real value of this tool is the ability to turn the engine with the plugs out by using a socket and 1/2″ drive ratchet with a reasonably long handle. All the worry about the crank chipping the paint are gone. This extension shaft now works like a champ to roll the big 8 cylinder over. Regards, Herb

<p style=”text-align: left;”> </p>

</p>