- Home

- About Us

- Join/Renew

- Member Benefits

- Member Pages

- Log In

- Help

- Museum Store

Tagged: oil filter, oil filter tubes, relief valve

I started on going through the oil pump. Dumped everything in the ultrasonic cleaner then dismantled the components.

I started on the pressure valve and ran into some issues.

When I removed the hex plug and spring I was unable to get the sliding piston out. There is a square headed plug that sealed off a drilled hole. I removed it, fitted a grease fitting and blocked the side access holes and pushed the piston out with my grease gun. You can see the piston at the right of the above pic.

While cleaning all the grease out I ran into what must be the smallest part of a Pierce engine. (Pencil point). This little spring was in the gallery under the grease fitting. It is an awful light return spring if that is what it is. Anyone know how it fits and what it does?

Bill,

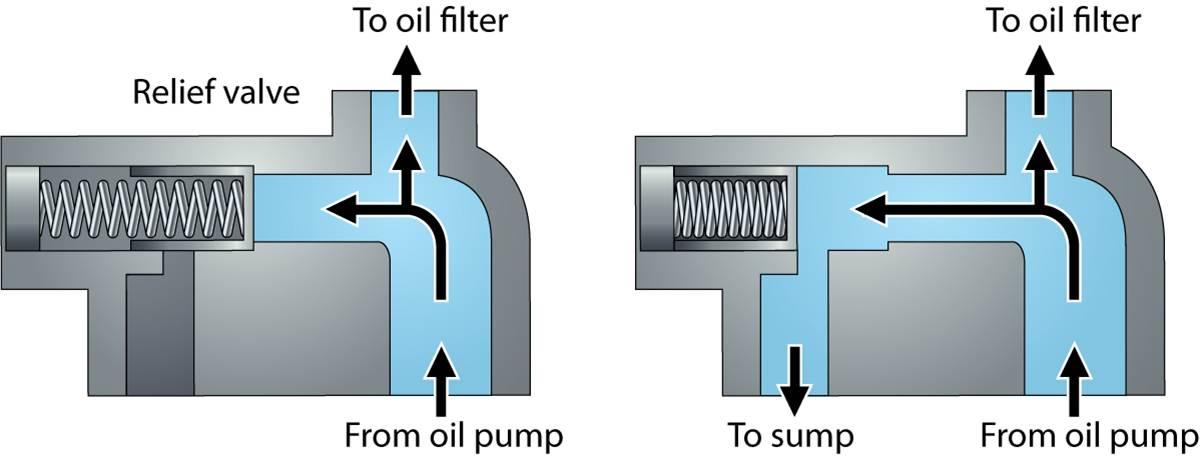

Step #1 is to trace out your oil flow diagram to confirm what is going on. The rumor is that all Pierces with oil filters used a “bypass flow” type connection. If the bypass flow device is on the high pressure side of the relief valve, then this is likely to be the port that is the inlet to the filter. The reason for a check valve on such a device is to allow oil to flow up and through the filter when the engine is running. When the engine is off, this check should close to prevent the accumulated dirt in the filter from draining back into the engine. Pierce combined these two functions into one device, there should be a small ball as part of this check valve. Happy hunting for it.

Hope this drawing (from Pelican website) helps: Herb

Possibly is it a springbfrom the grease fitting itself? Doesn’tbthese fittings have a spring-loaded ball which serves asca check to keep all the grease from backing out ofvthe fitting?

Randy, What would be the purpose of a grease fitting into the engine oil system? Is this a point listed on the lubrication chart? At best, the grease would dissolve into the oil and increase the viscosity slightly. If the grease remains in globs, it could clog oil passages inside the lifters or other small pathways in the pressure side of oil supply system. I expect it is more likely the threads in the relief valve body are for the tube fitting to the supply line for the “dirty” side of the oil filter. If the filter is mounted above the pump, then a check valve is needed to prevent dirty oil from flowing back into the engine when the car is shut down. What other device on the engine could provide this function? Modern replaceable oil filters do not have black flow if mounted below the normal oil level. Filters mounted above normal oil level do need a “flow back prevention” feature. Has anyone in the Society cut open one of these old style filters to see if there is an internal check valve? Regards, Herb

There is no grease fitting as part of the Pierce design; I was referringbto the fitting you mentioned using to force the plunger out to ith a grease gun. That is all.

After more research I am more confident the tiny spring is part of the zerk fitting used to force the plunger out. The spring holds the tiny ball check in place.

This is a known problem especially with some imported zerks of dubious quality.

Randy,

That would be a wonderful thing. I will try to stay away from dubious Zerks and women.