- Home

- About Us

- Join/Renew

- Member Benefits

- Member Pages

- Log In

- Help

- Museum Store

Tagged: pitman arm puller

Just wondering anyone knows what the torque should be for the pitman arm nut? There isnt a cotter pin on my ’30 PA either.

Thanks

Dave

Dave, Are you talking about the short arm off the steering box? That has a tapered shaft, so tight plus what it takes to get to the next hole for the cotter pin. I think there is 2 locations on the output shaft, so you should not have to go far when tight to find the next hole, after 50 miles go under and recheck for play, none found it should be good. Karl

Hi Karl,

Thanks for the reply. This is the short arm off the steering gear box. It is splined and does not have a cotter pin. Kind of makes me nervous not to have a pin.

Any thoughts are appreciated.

Dave

Dave,

You should have a washer with bendable tabs behind the nut. When tight, you bend the tab against the flat of the nut.

Karl

I think my ’35 with a Ross steering box is a similar arrangement, there is no provision for a cotter or grooves in the tapered spline to hold a toothed bend washer. I don’t know if original, but mine has a split ring lock washer.

I am in the same position, not sure how much to torque. The 1948 MoToRs manual just says to make sure the nut and lock washer are “tight’. Of course with the tapered spline it is very challenging to remove the arm with a puller after being heavily torqued. Split ring lock washers do not provide any resistance to loosening when flattened, the teeth can only dig in to resist loosening after the nut has turned enough for it to unflatten. This may be enough to keep the pitman engaged in the splines and start warning something is amiss from clunking and before disaster – maybe not.

My plan is to use a new grade 8 split ring washer so the teeth don’t blunt when the nut is reversed and use Locktite 242. Locktite is considered more reliable than split rings. I am thinking of doing around 70 ft lbs torque but in the end will do it more by feel.

Dave, Jim:

May I suggest using a Nord-Lock washer? These are superior to a split ring or toothed lock washer. A bit pricey, but worth it.

http://Nord-Lock® Washers https://www.mcmaster.com/Nord-Lock®-Washers

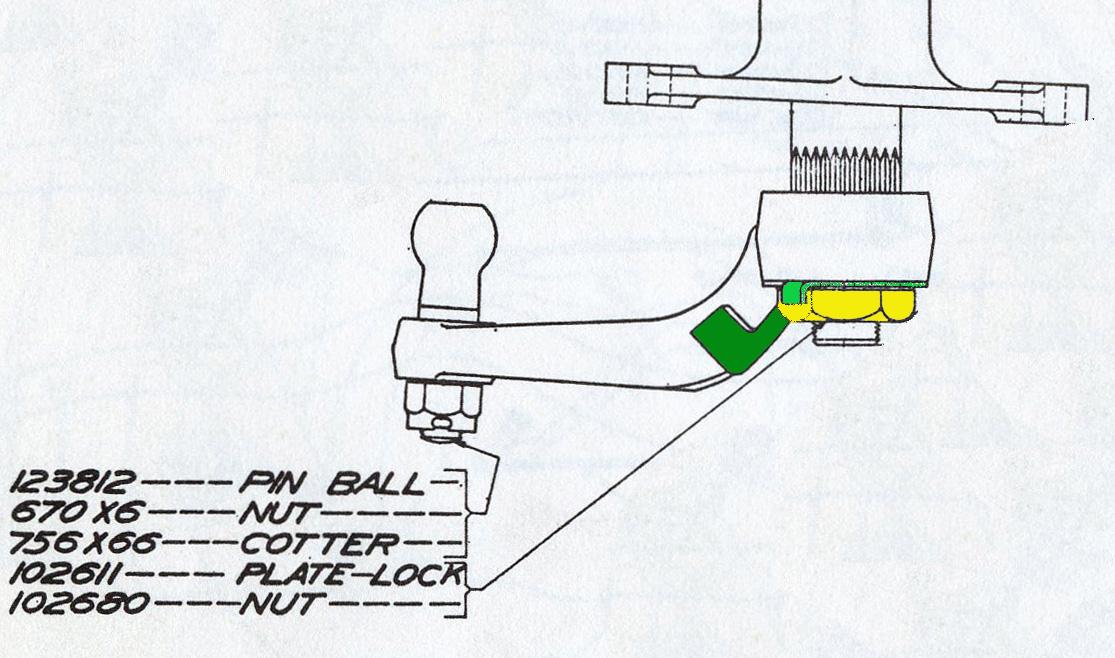

As Kark K explain – you should have a washer with a bendable tabs behind the big nut. Here is a drawing from the 1930 part book. (continue)

Here is my washer with the tab. (continue)

Here is an orignal one from a part car.

Oivind – Interesting. Yet another thing to look for/at. Thanks for the photos.

Interesting, both the Nordlock and the original bent washer that wraps around the Pitman. Presumeably my ’35 had this originally.

I have never seen one of these, not that I have had much reason to look. I assume they are not available and missing on a lot of cars.

This looks like something that lends itself to computer controlled laser cutting of the flat pattern. It could be bent in situ after that.

I have had several other pieces laser cut for my Pierce so far at really inexpensive cost and currently getting a quote for several bits to make grille louver hinges and links.

Do you think there would be interest in making a short run of these?

I was a bit too quick off the mark. The configuration for the 1930 bent tab washer shown above looks fairly straightforward to reproduce, but my ’35 is clearly different. It has a special nut going into a deep recess in the pitman and the washer ends up deep in the hole. I wonder if what I have with just a split ring was how it was originally?

The bent washer is also on my ’29 and is probably what should be there. Looking at the step in diameter between the threads and spline, I would NOT recommend a split washer as it is likely to damage the end of the spline. If your car has the Gemmer steering box, the threads on the steering box output shaft are probably 7/8 diameter and 14 threads per inch, which is the standard UNF series. I would treat this shaft no more than a Grade 2 bolt, which has a recommended torque of 83 ft-lb. I agree with Ovid that the torque should be about 70 ft-lb as a conservative number. Using a little less torque will keep from stretching the threads. I treated mine as a bit less than the Grade 2, so will also end up about 70 when finished. With the bent tab restrainer, the nut will stay in place at this torque. Having a source of new restrainers available is a very good idea, as the tabs do not take many uses before breaking off, and most of our cars likely had this removed a time or two over the years. The only special feature of these retainers in the leg that goes down to hold around the Pitman arm and keep the whole assembly from rotating.

Once you have the nut off (1-1/2″ wrench), you are only half way done. The more difficult part is pulling the arm off the spline. It won’t fall off by itself. If you still have the fenders in place, a standard three leg pullers will not fit in this cramped area. I found a puller for the current F250 & F-350 (Lisle #41970) is short enough to fit. But you need to reverse a shorter (1 inch long) bolt so that it is on the inside of the puller, making it possible to fit under the fender / running board support and still get a wrench on it. Email me if you want some pictures of the modified puller.

@Herbert Tull,

How about this one from OTC? Is this similar to what you did with the Lisle puller?

This puller is probably similar, but (1) measure the distance between the two jaws to make sure it easily fits over the spline. Too tight will damage them if you have to pound the puller into place. (2) Check the overall height to make sure it fits between the arm and the fender. See you in Hershey!

Thank you all very much. I had this in the pile of parts and didnt realize that it was for until now. I plan on having a new one made. If anyone is interested I plan on seeing what it would take to get the programing done and laser cut new ones.

Take care

Dave