- Home

- About Us

- Join/Renew

- Member Benefits

- Member Pages

- Log In

- Help

- Museum Store

.

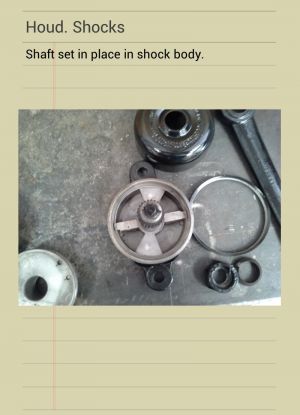

The check balls are held in by a small pin and again they freed up, no spring this time.

According to the Pat. App. the holes are for air to vent from the working chamber so they go up as near as possible when installed in the car. The almost opposite holes are plugged so I think the cover is clocked to the housing and they used the best match and plugged the other two.

.

.

.

.

Before taking the shocks off the car I sugges that they be stamped for each corner and after taking off the nut, use a sharp chisel to stamp a witness line in the end of the shaft and the lever/arm.

Great photos.

I would love to see a complete writeup with the pictures included in a future service bulletin.

Great photos and update. I used 5 weight fork oil in my 1936 1602, and the adjustment worked very good. I don’t remember all the details but a little adjustment and we had the ride much improved, and it worked quite well. That was 29 years ago, and no more adjustments have been necessary.

Excellent presentation!

MAGIC photos Jim. Thank you!! Also this website (It has been posted on the message board a few times before)gives good practical info on Houdaille Shocks. At the bottom left of the last page is other pages on rebuilding etc. ALL very relevant to Houdailles fitted to our cars as opposed to Ford & other types.

Jim (et al)–

This absolutely needs to be an article for the PAS Service Bulletin! Please take the time and trouble to write down your procedure and send it to me, with the photos. I will do the editing (I am an “Editor”!) and submit the draft to you for review and correction before publishing. Conventional wisdom is that shocks are too difficult for amateurs to rebuild. You are proving the contrary. We need to let everyone else know.

Thanks, Arnold

Jim,

You can click on the member’s name in the message header to send the member email or look up members in the Roster for snail-mail/phone contact.

Paul

Hi Jim, thanks for the excellent photos.

What tool or tools did you use to remove or loosen the lock ring, and the resevoir cover?

I looked at a few dirty shocks I have and I see no way to grip the ring or the cover other than a pipe-wrench, or very large channel locks. or maybe for the cover, an oil filter band/strap wrench..

Can you help with some tool suggestions ?

Thanks, Greg Long

Greg,

I assume that you already have the arm off.

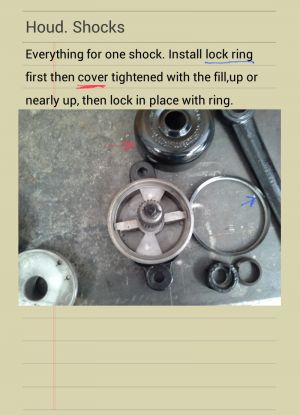

Look at the lock ring and there are 2 or 4 round holes that don’t go all the way through the ring. I had both 2 and 4 on mine.

After using penetrating oil for 2 days use a 1/8″ punch and tap the ring at an angle in the holes to loosen it. If it won’t move I used a cutting torch to heat the ring gently and tapped again. I like the cutting torch better than the rosebud tip bucause the heated area is smaller, just don’t touch the cut lever. Don’t get the parts red, you just want to expand them a little.

After the lock ring is backed off a little I heat the reservoir the same way and use the vise grip chain pliers. They grip well and don’t damage the cover. The oil filter strap wrench might work, I just use the VG for anything odd shaped. Work the cover back and forth and when loose unscrew it all the way, if you don’t and let it cool down it wants to bind in the rust again.

Pay attention to the mating surface of the lock ring and you will see that it is tapered, when you reassemble do it the same way. 1 of my rear shocks looked like there was a thread sealer or caulk between the 2 pieces the other looked like tar. It looks like a #244 o ring would would work in that position but I don’t know if it would allow the ring to lock against the cover. When I get the shaft seals I might try the plumbers teflon thread sealing paste.

When you get that far the easy part is over..Any other questions just ask.

Jim

Bill Morris put a couple of internet links on the Message Board back in March. One of them is obsolete.

The one for the Ford type Houdaille 40 page manual is

http://www.oldcarmanualsproject.com/manuals/Ford/Haudaille/index.html Yes Spelt with an a not an o.

Jim’s step by step instruction is Magic!! Just wait until he gets to the 6 foot long spanner bit!!

I decided to use hyd. jack oil, and the action after moving the arm to purge the air, the 2 I did seem to be working fine through the whole adjustment range. Definitely a single action shock and Lefts and Rights.

Jim,

I found that I have digital scans of the Houdaille workshop procedures for these shocks. Do you have them? If not I can email them to you.

Bill

Bill,

Yes I would like to have the scans. The only info I have is the patent pictures and the physical shocks I have taken apart. Thanks Jim

Hi Bill, please send the scans to me as well.

Thanks,

Greg L