- Home

- About Us

- Join/Renew

- Member Benefits

- Member Pages

- Log In

- Help

- Museum Store

“4) Who has more knowledge about these issues than the members assigned to propose the best solutions for the Society and all of our members?”

Dave, I agree that the people involved in presenting this solution have worked hard and believe what they are presenting is a good solution.

That said, this is a major change in response to a minor software glitch. Personally, I’d prefer to lose a post every now rather than lose the privacy of our current forum. This is just my opinion and is not a criticism of the hard work mentioned above.

It may very well be a good way to publicize our club, but in looking at the Pierce Arrow forum that’s been on the AACA forum for years, it’s little used. Unless someone is using the “new posts” option when viewing the AACA forum, one has to go looking for the Pierce Arrow forum there, and very few people do so. Moving our private forum to that site won’t make that change.

I participated in the Zoom meeting, and first want to thank Jane, Liz, and Karl for a very nice presentation. In particular, Liz presents a strong argument for the proposed move of the Pierce forum to the AACA site.

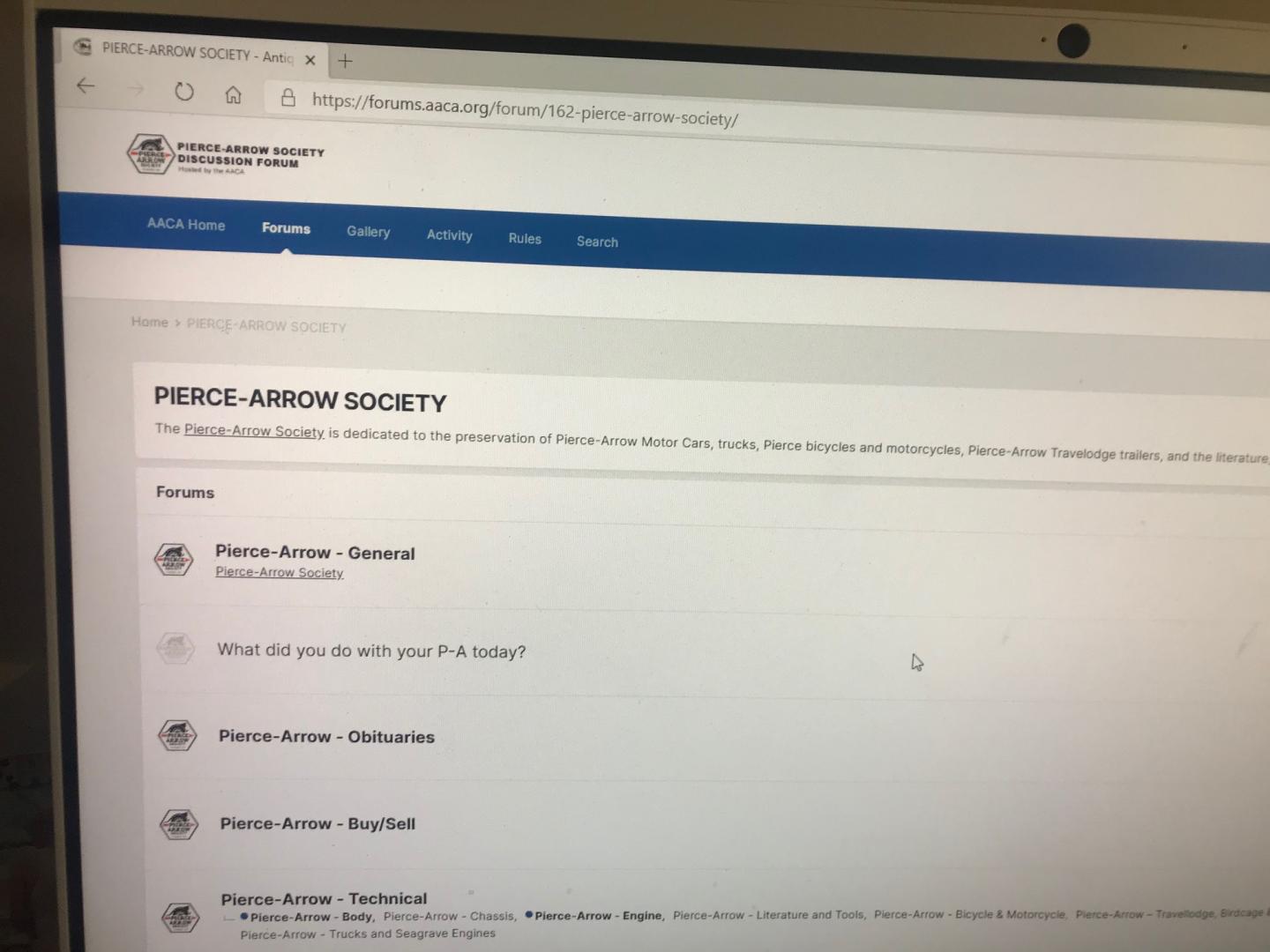

It doesn’t appear to be “proposed”, however, as it is now live on the AACA forum, with our topics, and in the upper left hand corner “Pierce Arrow Society Discussion Forum hosted by the AACA.” Comments have already started being posted there, from AACA signed in users, so unless this is just a live demo it looks like action has already been taken (see screenshot attached).

I appreciate the fact that it might give us some exposure to the general public, but therein may lie the problem. The AACA forum is NOT just for AACA members, it’s open to anyone and everyone who takes a couple of minutes to register.

During the meeting, Jane pointed out that I put my name on my AACA posts. If you wish anonymity, the AACA forum is not the place to do it. Early on I just went by my user name, Trimacar, but it didn’t take long for someone to comment something like “Wow, had a nice talk with David Coco (Trimacar) and he was a big help.” Cover blown, so to speak.

I equate our forum moving to the AACA site to having a nice little family gathering, all your kin you can say anything you want to, then inviting hundreds of strangers to join the gathering. The cozy tone and feel of the gathering is then lost. Discussions on the AACA are not private discussions, but rather public record and subject to severe criticism. I know, you can delete some postings, but that can have a negative effect on the Society when the censored user complains about the Society elsewhere on the Forum. Censorship is not taken lightly by many users on that forum.

I have over 8000 posts on the AACA forum, and I daresay I have a good reputation there, but I’ve also been called an idiot and had someone tell me “hope you’re not in the educational system because you’re posting stupid things”. The AACA forum is a great tool for communicating, but it’s also has, at times, an argumentative and confrontational tone. Moving there will change the complexion of the PAS forum to a large degree.

Thank you David Coco Winchester Va.

Thanks Dave … I haven’t decided one way or the other, but I do have concerns about going to the public forum of AACA. Just the thought of comments about frogeyes give me pause.

I agree you can moderate, and even delete posts, but I’ve also seen those deleted people pop up with comments elsewhere on the forum, “yeah, well, you can’t discuss anything with those Pierce people” kind of thing.

I’ve spent way too much time on the AACA forum, have over 8000 posts, and just think the feel of the AACA public forum is different than the cozy feel of the PAS Message Board.

In addition, but I guess a small point, on the AACA forum a PAS member could no longer post something like “Hey, I used XYZ chrome platers and they are terrible, don’t use them as they’ll rip you off.” The AACA is rightfully afraid of lawsuits and open discussion on negative aspects of vendors is discouraged and deleted.

I hope to be able to attend the Zoom meeting and have an open mind, but also have concerns as mentioned.

From what I now know (and someone correct me if I’m wrong), everyone and anyone signed in to AACA forums would be able to see and respond to any of our posts on the PAS forum.

The “members only” sections would still need PAS membership and login to access.

My thought, after years of being active on both forums, is that being on the AACA site will change the tone of our discussions somewhat, when anyone can EASILY see the posts and comment. Before this change someone had to come looking for us, now it’ll all be very public. There’s a lot of negativity on the AACA site, and we’ll have people criticizing some of our discussions. I’ve seen it daily, there are just some people who love to criticize and don’t hesitate to do so. Oh, wait, am I one of those? Hmmmm….

One argument is that “Well, people have to come looking for the Pierce forum on the AACA site and few will”. That’s not quite true. There’s a feature which I use, called “new posts”, that brings up all posts from all sub-forums since your last visit.

Does the additional exposure help the Society? Possibly.

None of this takes away from the fact that numerous people of the PAS have put in a lot of time on the new forum here, and that’s appreciated.

Can you give us a little more information please. Would this mean to view the PAS forum, one would go to AACA forum site? If so, would that mean anyone signed in to AACA forum would have use of PAS forum? Thanks dc

Although most all believe that the market is down, I think the prices realized are more an indication of condition adjustment than they are a market adjustment.

Project cars just don’t bring what they used to, because one has to factor in the cost of repair and restoration. What used to be a few thousand dollar paint job is now (according to a local shop that does antique car painting) $10,000 for a driver, $20,000 for a show car. The labor for an interior can run $10,000 to $15,000 easily, and that’s not counting materials. Chrome is out of sight, it’s like a game to see how much you’ll pay for shiny.

Nicely restored, well maintained cars will still bring fair money, but projects will go begging, and I think these prices reflect that. Just my opinion…dc

Nice, thanks for posting, I have a set to work on too!

He’s offered the $1000 reward for 6 or 7 years, not a shred of proof has turned up. It’s a real interesting assemblage of parts, but his description is sure flowery for what it is….

The only true words in the description are “built”, “found by Mike and Frank”, award for some reason, and “can be inspected”….everything else is conjecture, or as they use to say, a tale woven out of whole cloth…

At one time Merlin Smith was talking about having doors recast, that’s the only part that says Pierce, and the rest of the stove, while not easy to find, is a standard stove of the time, I forget the brand. I know an original sold a few years ago, but they are more rare than the trailers, and there aren’t that many trailers.

Just for history sake, the originals were two piece, a right and a left, and the joint was centerline of car front and back.

I’ve been told that sometimes the radius right and left may not match exactly, I could be wrong.

I’ve seen using the plywood as a pattern to bend the strips, from what I remember the person doing it stated that each curve was different, so started with the biggest radius, and cut same plywood board three times to make the other three pieces.

I have a top to install on a Packard, and frankly don’t have the time nor skills to bend the metal. I’m considering just installing a piece of hidem for now, then the owner can pursue metal if he desires.

I did a Pierce 840 not long ago, had the original metal strips, they were similar to #3 above, thin metal and very flimsy.

I run a small bead of sealant on the ridge inside of the tack holes, then I can peek under the fabric to see where the holes are. Once you get a few tacks in, then finding the edge of the other holes is by eyesight. Using a piece of blue painter’s tape isn’t a bad idea at all, I use that (and the green body shop paper) all the time when I’m doing upholstery work.

I’d be interested to know what people are using for final trim, if they don’t have the original pieces. I know you can buy aluminum strips and bend them, is there anything more flexible out there that works? I don’t want to use that ugly hot rod stuff that’s available, and I have a top to do right now.

Most cars had oval shaped slots in the metal roof edge, usually the tack that holds top material goes in one end, the fastener for trim goes in the other end.

It was common practice to coat the original top with a dressing to help keep it waterproof. A lot of companies supplied these dressings.

As you mention, I think the original material had a slight pattern to it, but it was much smoother than the (what I call) heavy grain on current cobra materials.

I think the replicated Pantasote is possibly closer, it has a slight pattern but not much.

I’d be interested to know what trim you’re using. Do you have some original metal trim, or?

Appears to be a long grain cobra material. Eric Haartz does have some oddball material stashed away, Bjorn could clarify exactly what he put on the car.

My opinion is that the original material was a very faint grain, and not the pronounced grain of most top material now found. Not quite a smooth Pantasote material, but not the heavy raised ridges either. That’s just my opinion.

Kudos to Eric, he’s a great resource for us early car guys, always willing to help in any way he can, when he could just as easily ignore that part of his huge business…

That is the repainted car, was the one that showed up at, I think, Buffalo 100 year meet, painted purple. Fellow sold the car and had it repainted in about 2005. Very nice car to say the least…

The car looks great in the side view! I’m not a fan of all those lights, but to each his own. At first I was appalled that someone driving it was smoking, then remembered no interior! Hope your trimmer knows what he’s doing, no foam and the correct padding for the top…good luck!

Great find, apparently a rare car from a very obscure maker. All aluminum, company only in business in the 1930s for five years….you scored a Pierce not often seen!

One issue with Babbitt is when you go undersize on the crank, the Babbitt gets thicker. Babbitt doesn’t transmit heat well, so the thicker Babbitt tends to get hotter and start to come apart. Or, at least that’s what I’ve been told over the years.

I have inserts on two straight eights, my ’31 Pierce and a ’38 Super Eight other P car, and am very happy with them. On the ’31, the rods were built up slightly on the sides to compensate for no side Babbitt, if that makes sense. On the Packard, we just brazed three spots on each side of rod and made a jig to machine to size needed, and that’s what replaces side Babbitt. There’s virtually no side thrust on the bottom end of a rod, so all that’s needed is a spacer to replace the side Babbitt.