- Home

- About Us

- Join/Renew

- Member Benefits

- Member Pages

- Log In

- Help

- Museum Store

That’s great! What kind if condition is the car, and what are your plans? Drive it as is fixing what needs to be fixed or some level of restorion?

Have you determined the gauges aren’t working?

I have been using the stabilant 22 on some of the semi permanent junction block connectuons on the Pierce, I have no idea if it is just over egging the pudding.

I did find the deox but for a different application – the pot on my 40+ year old Marantz turntable speed sync control. It wouldn’t hold speed, but a few squirts helped. Thanks, Jim

Yes, the trunnion block is what I call the kick shackle.

I have a ’36 Packard with vacuum boost cable brakes and it works well, as far as boost is concerned. The unit has some corrosion inside where the seal sat for decades so sitting at a stoplight it has a bit of a vacuum leak that leans out the mixture and causes a minor stumble at idle. It doesn’t effect the boost. They are a bit grabby when cold but quickly lose that.

My Pierce is still a work in process and I have only driven it in short spurts up and down the cul de sac. I can say that the Pierce brakes work very well and unlike most drum brake systems seem to work as well backing up as going forward.

I have been anxious for 30 years to see how they work on the road. The challenge for any mechanical brake system is to get them adjusted. They all have some degree of mechanical slop in them that is minimized the tighter you adjust them but some level is needed so the shoes aren’t dragging and overheating. Pulling to the left or right is the biggest concern, next is the delay from taking up the mechanical slop. The torque tube on the Pierce I think has the potential to be less prone to uneven pulling, but I don’t know that yet. Both Packard and Pierce are solid front axle cars with an interesting device called a kick shackle on one of the front spring shackles. It is there to reduce the tendency to develop nasty steering shimmy when “balloon” tires were introduced. Packard and Pierce have different designs for these. The kick shackle introduced a new problem, when the front brakes are applied the force gets fed back into the steering arm and the front brakes had to factor this out by tweaking the geometry of the front brakes to pull a bit harder on one side than the other.

There are so many variables that come into play comparing the system on any two cars. One of the main ones that throws things off is the brake lining characteristics. Original linings were relatively soft asbestos which is hard to find. Newer modern linings are often too hard and have very different characteristics which can be extremely grabby one minute and fading the next. I had my Pierce relined with newer material that is supposed to be relatively soft and a suitable replacement for asbestos, but I won’t be able to judge until mine is actually roadworthy. As of a few years ago it was still possible to get asbestos linings for mid ’30’s senior Packards (if I remember correctly Pierce used 16″ diameter and Packard 15″).

Another variable in the S-W system is the clutch that activates the brakes. It is basically a disc brake with a soft lining that is immersed in the transmission oil. When you push the brake pedal you are applying pressure to the clutch to apply the torque coming from the driveshaft to apply the brakes. The original clutch material is no longer available and units that have been rebuilt generally have a Kevlar material that has been found to be a suitable substitute. Although it is clearly suitable, it probably is not an exact match for friction characteristics, so throws another variable into the comparison. I was very lucky on mine, the original material was intact with no significant damage or wear, so should work per original – except for those non-asbestos brake linings.

I should add that there is a lot of info available in the Pierce-Arrow Service Bullitens that are key word searchable and downloadable on this website.

I understand that Rolls-Royce used it. It is a more expensive unit to manufacture than a more typical vacuum booster unit. In ’36 Pierce went to a vacuum booster. If I remember correctly it was because the new overdrive unit added didn’t leave room for the S-W unit anymore. The whole transmission, freewheel, and S-W brake unit makes for a pretty long assembly.

Of course this brings up one of the challenges and debates about restoration, form vs function and the compromises. Restoration – meaning to restore to a previous condition – implies everything is returned to what it once was. In practice auto restoration tends to be interpreted to mean that to score points it just needs to look original and anything goes if it isn’t easily visible. Form over function.

Of course conditions are different now than 80 years ago and the way we use the cars is different – a lot if sitting and little if any actual driving. Fuels are different, freeways with uninterrupted high speed driving, etc, Original parts deteriorated and unavailable.

Compromise is inevitable. I do like to work to make the original stuff work as original, and I like using the original parts as much as practical so I do patching and repair where feasible instead of ripping stuff out whole and replacing with new. I think of the USS Constitution where it once was estimated only about 1/7th of the original ship is still there. Restoration or reproduction? No definitive answer. However some things I do to improve practicality in the real world. Electric fuel pumps, bypass the leaking oil cooler, modern oil filter, auxiliary air source for the fuel gauge, coolant filters, halogen headlight bulbs, seat belts, etc. Restoration in reality is full of compromises that leave lots of room for debate.

A bit off topic, but basically some members have been able to make the original fuel gauge work well with attention to detail, and I decided to try and do the same.

That is a torque rod that applies the front brake shoes. There is a bellcrank and cable inboard on the axle that runs back to the unusual power brake system (33-35 only). This is instead of conduit and cables going directly to each wheel on a mechanical brake system. The Stewart Warner power brake uses the torque of the driveshaft to apply the force to the brake shoes via a clutch system on the back of the transmission and free-wheel unit. The brakes are very powerful but often there is a tendency to creep at stoplights.

I have spent many hours trying to dream up a fuel gauge that would look original but have reliable workings, including some barber pole arrangement like a 64-66 T-Bird speedometer or coatings that change color with electric charge. Unfortunately my technical know how falls well short and I didn’t come up with anything. I am using the original gas gauge system but installed a bit of a cheat that I hope will keep it working in case of sending unit problems after sitting for awhile.

A lot if cars retrofitted universal dial temp gauges in the original hole. They obviously don’t look original, but a compromise might be to replace the facia card with one that matches the ammeter and oil pressure style.

I can dig up the temp gauge guy contact info if needed.

The water temp gauge is more likely to work, unlike the fuel gauge it is a sealed system and as long as the seals are good it should work. The dye in the fluid may have disappeared making it hard to read. The solder joints connecting the tubing are a bit delicate and easy to lose the seal.

I had mine repaired for a modest cost by the “The Temperature Gauge Guy” several years ago but at the time he was hoping to retire and pass the business to someone else, I don’t know the current status.

The thermosylphon unit that controls the grille shutters on mid ’30’s was usually set to be fully open at 160 degrees. Engine temp will go above this on a hot day. The gauge on mine leaves it ambiguous, as it doesn’t read temp, just hot and cold.

Good luck!

It would be great to see someone who knows what they are doing!

Obviously not me, it took me 3 or 4 days.

Bill Hirsch has a good variety of authentic wool broadcloths, including some of the subtle striped patterns. They are listed as “Packard striped” but look like a good match to what I could interpret from my original Pierce fabric.

Great idea, thanks!

Bill, I had no luck finding a grommet like that, I still had one marginal original and used it but not the other. Maybe someone else has found something.

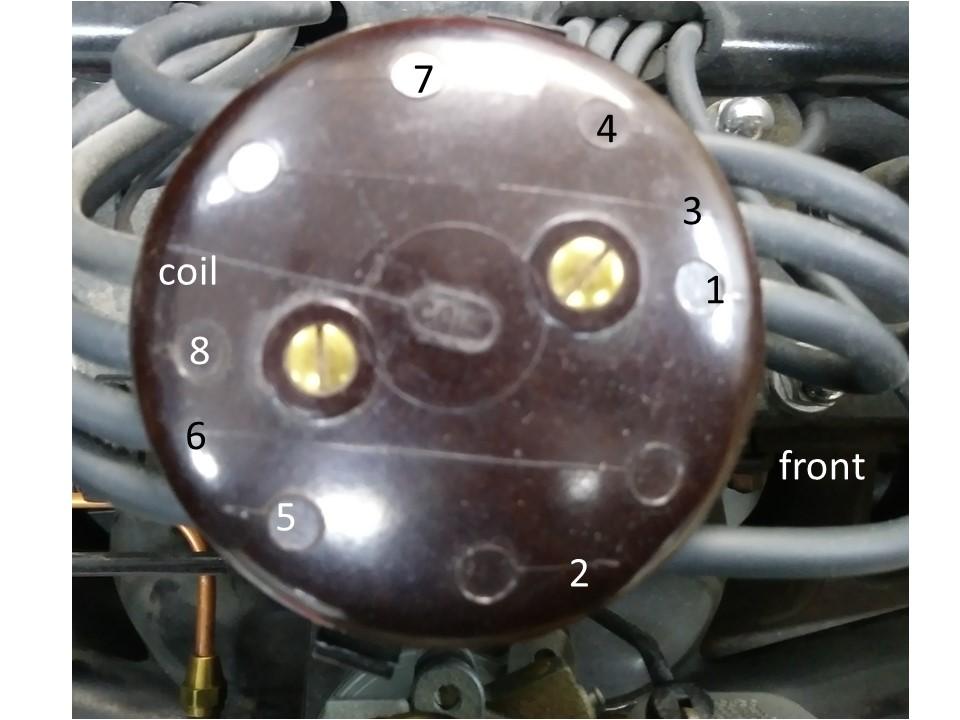

Bill, the distributor faceplate on my 845 faces forward. I believe your ’33 has the same 662J distributor. Here is a picture of my cap with the wires. I did this by pulling the wires in the tube so you might double check that this matches the firing order.

On mine I didn’t realize that there seemed to be only one combination of the distributor/gear pump mesh that would allow the distributor to face forward and allow the wires to come out in the proper direction. The distributor drive key is slightly offset if I remember correctly so it isn’t just a matter of turning the distributor rotor 180. I ended up having to drop the pan and remove the oil pump and find by trial and error a mesh that would work between the cam and distributor/oil pump drive gears. There is probably a smarter way to do it.

Looks great, a big milestone, congrats! A huge amount of work to get to this point. I am hoping to get there in a few months myself.

I only have experience with the late ’35 version. Can Greg or somebody confirm the tappet is original? The shiny band at the bottom looks suspicious to me and the spring gauge gives me the impression that it might be stiffer than the springs on my ’35 (mounted externally like ’36). Wondering if this may have been modified from original to try and fix a problem?

Are you sure they are defective?

Looks like the original ’33 to mid ’35 due to the spring being down in the follower rather than above. Not interchangeable with Cadillac.

Bill, I work cheap but the number of manhours is a killer. I think others do it in a day, it took me four or five.

Dave, there is a long string on the message board a couple years back about the “correct” pattern that can be found doing a key word search. Apparently Eric Hartz did a special run that matched somebody’s sample and needs a call directly to Eric to obtain. I think others have done that and might respond here.

The whole discussion left me wondering whether there really was ever any one pattern used consistently. I have no intention of ever having my car judged, and my goal has never been to do a slavish recreation of the car when it left the factory. I lean a bit towards function over form (no it doesn’t have a 350 Chevy).

Looking at the pictures I took of Paul Johnson’s original ’35 (thanks Paul) it appeared the grain on his car is more subdued than the usual cobra long grain I used on my Packard decades ago. Colonial grain is more subtle and looked like a better match so that is what I used. I bought it from Mac’s.