- Home

- About Us

- Join/Renew

- Member Benefits

- Member Pages

- Log In

- Help

- Museum Store

Welcome to the Pierce Arrow Society! Make sure to tell your friends that you aren’t in a Club, but rather a Society! You’ll meet some great people here. So glad it went to someone who appreciates it, and will get it back on the road. Don’t hesitate to ask the group, or individuals, questions….

It does have a new owner, lives in Pennsylvania. I don’t have the name but someone who frequents this site does, so stay tuned and he should chime in.

Top looks great, correctly padded and nice and smooth. I had to put a new top on a 1932, the guy had installed it in the dead of winter, it flapped at 30 miles an hour. Well done!

I stopped for gas in Dolores, Colorado, a few years ago, looked up and a Goose was sitting there next to a small museum. It’s a little like Washington’s hatchet, though, the Pierce body was replaced by a Wayne body, the Pierce engine was replaced by a GMC engines. At least the radiator shell was still Pierce!

That was in the Calvin High Collection, who had the finest early to mid-30s convertible coupe assortment you’ve ever seen….Marmon, Stutz, V-16 Cadillac, and so forth….all in 100 point condition….

Which is absolutely correct, but you’ll find that a heavy broadcloth is quite a challenge to get into that little slot. I usually just glue the material on, leaving as small a tail as possible that you can push into the slot with a screwdriver or other flat device. Thinner material, such as headliner, might work better.

What number does the title have on it? If you can’t match a number on the car to a number on the title, you’re really taking a chance buying it.

Looks like a nice car though.

Well, thanks very much for reply! I know Rich and will contact him, thanks!

You missed a good one!

Great job by Karl and others, it was a wonderful event. So good to see all the old, and meet new, friends enjoying the cars and company. There were over fifty first timers (first PAS meet attended), which is not only believed to be a record, but bodes well for our Society.

Only problem was that when I got home after the meet, had to start a diet, those Pennsylvania Dutch just keep the food a’comin’!

Many thanks to Karl, Mary, Rick, Liz, and others, for making the effort to make this meet happen.

The material is called a “no fray” fabric, you can buy it at most fabric stores. It will have somewhat more of a weave evident. Getting it in the slot is virtually impossible, add about an inch and a half to length and glue it one full round. All that said, it’s a bear getting it perfectly even, so the next best thing is….

…go to the fellow who restores these for a living. Not terribly expensive and you don’t have to fool with it. About $100 per shade restored.

Heritage Antique Automobile Interiors

1784 Ramblewood Avenue

Columbus Ohio 43235-7332

614-451-8893

I have a master mechanic who does engines, mainly race and Porsche engines. If you’re a friend, he’ll work on your old stuff. His advice on my 1938 Packard Super Eight engine he worked on, torque rod nuts to 40 ft-lb and do NOT put in cotter pins. He states a properly torqued bolt will not unscrew itself, and having pieces of cotter pins in the oil is not good for engine….

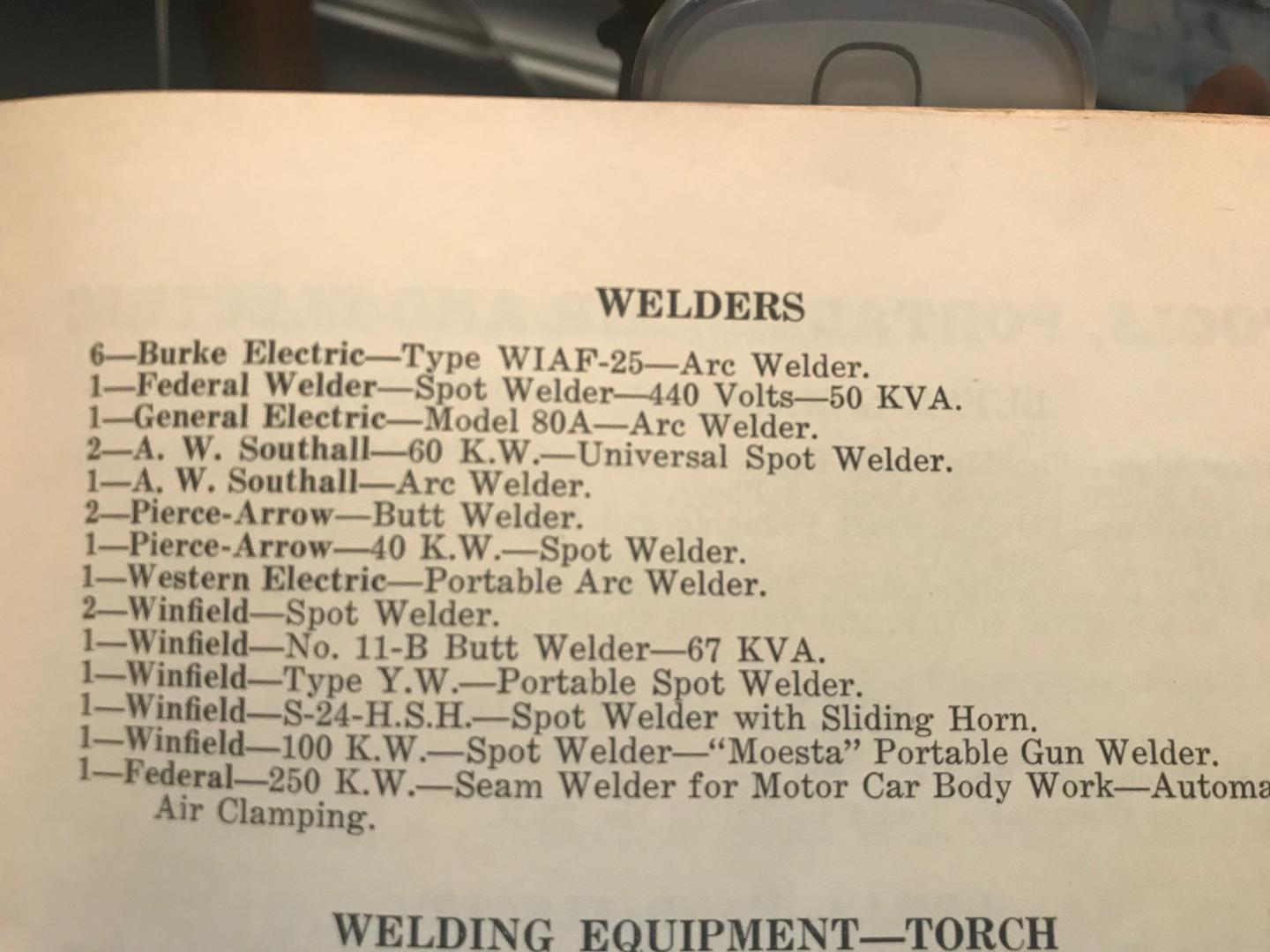

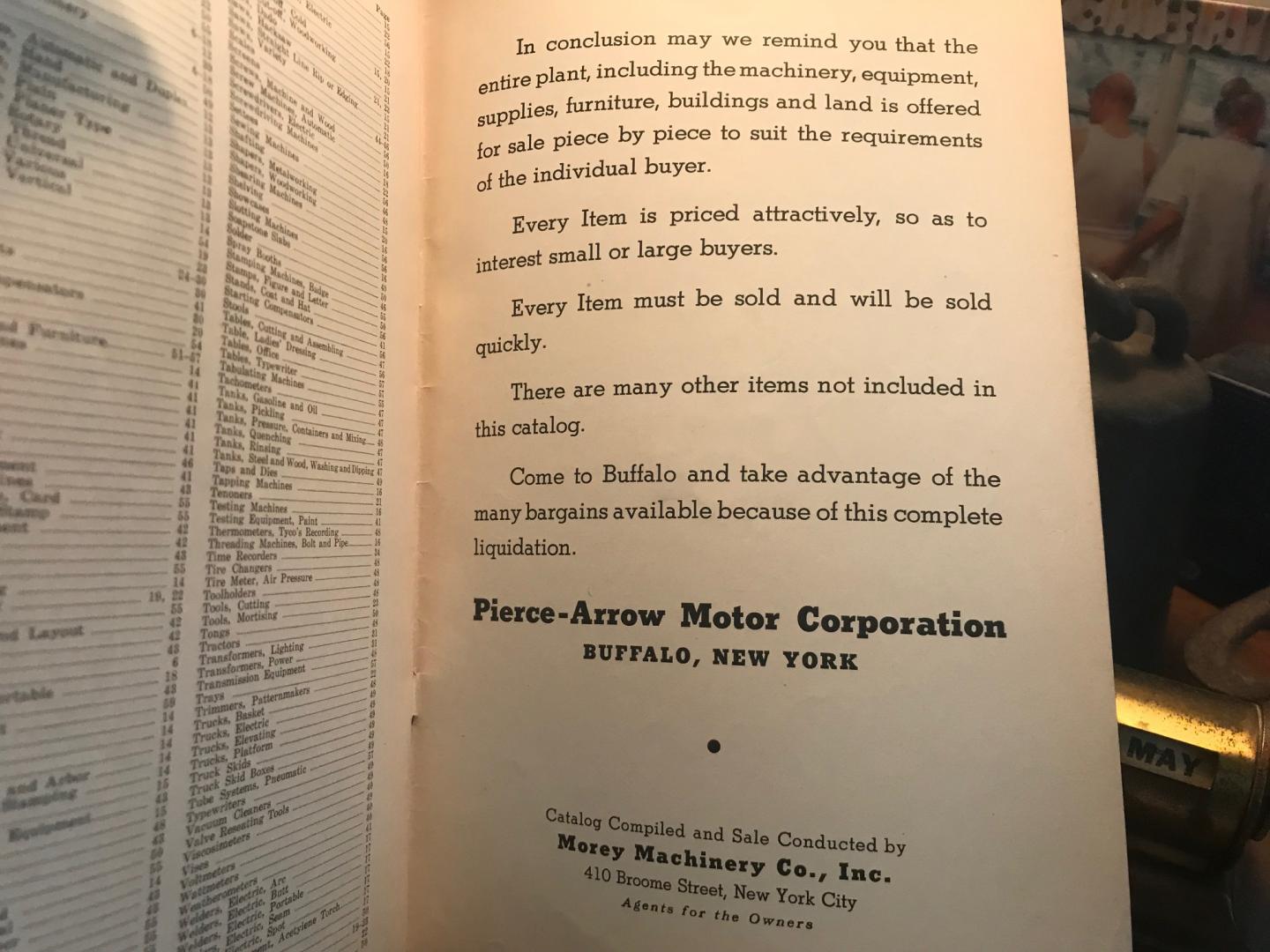

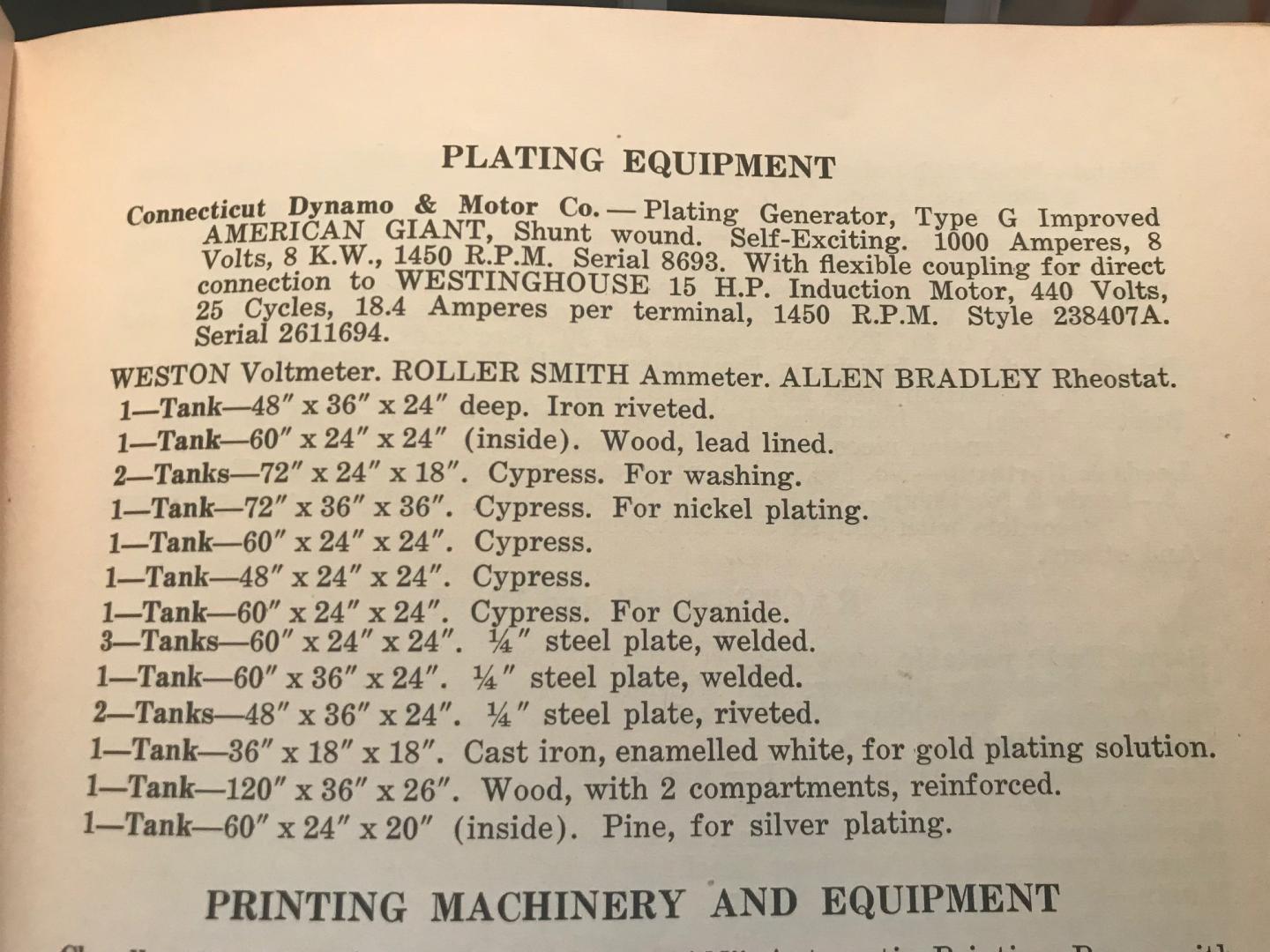

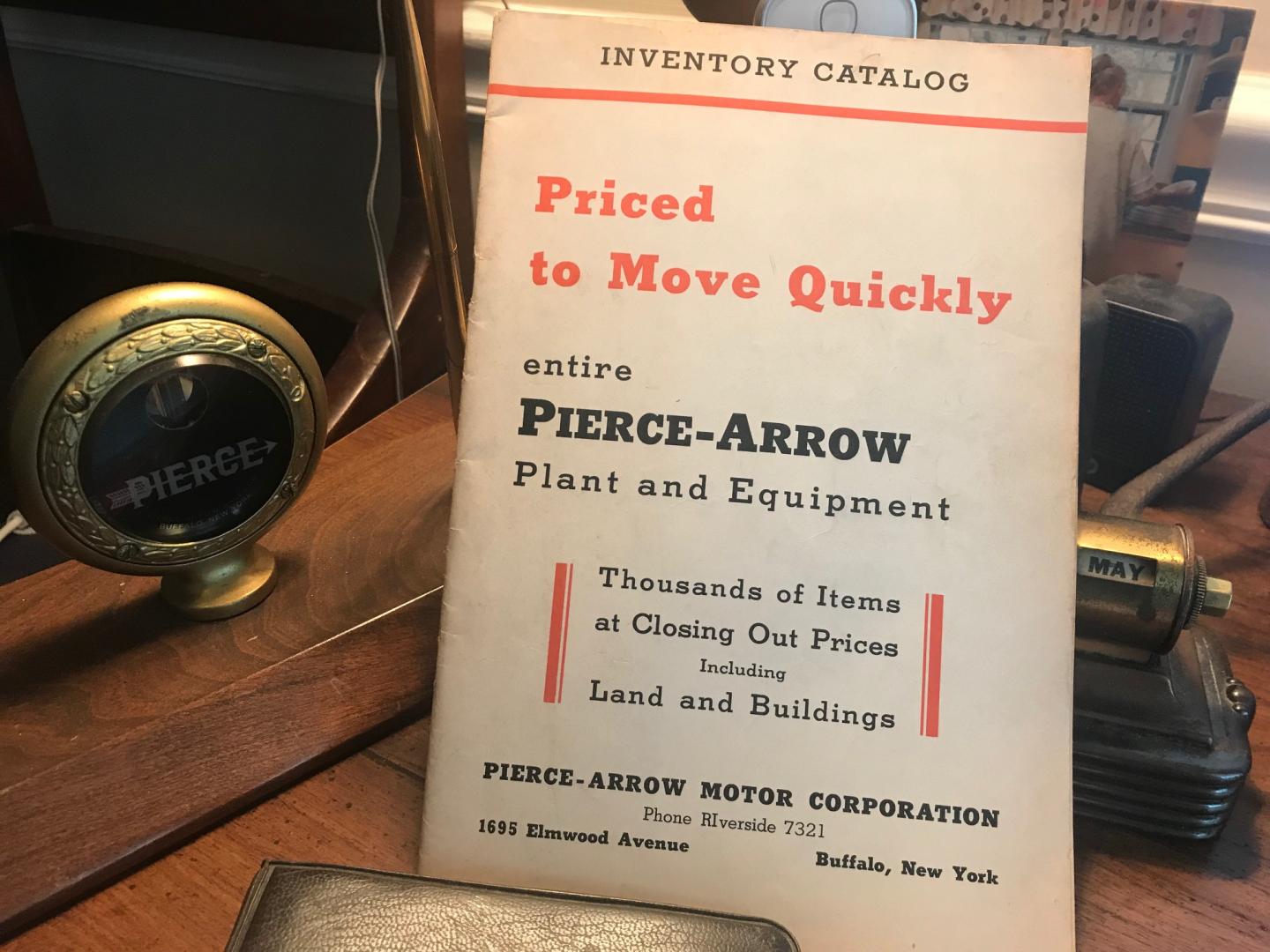

Liquidation and published a booklet for all the inventory, quite interesting to see all the machinery that was in the plant….

Yowsa….I was never exposed to early motorcycles, sure wish I had been back in the day….prices have one sky high, wonder if long term values will stay there..but, if one has the money, they are beautiful toys…

Jim, excellent write up, I’ve restored three 34-35 closed cars and they all had this problem. I remember well having to do the offset holes so that the handle shaft would line up inside the wood trim. I wish the new brackets had been available.

This should be published in the service bulletin. Thanks David C.

Thanks Craig, a lot of work went into getting the mats nicely done. I know about what you mean on minor differences, and know about them, but some things I couldn’t quite get the fabricator to go along with. The ribs are the big thing, lots of work. I think at this point just a couple of people have shown interest, I’m not doing anymore, and the cost to do a few more is high.

The close up above makes the mat look funny, but I can tell you, as Craig mentioned, they are really pretty. Thanks David C.

Beautiful bike, does anyone know the history on this one? With replicas being built it ‘s so very important to know if is real….with an engine one can build a bike…

https://www.mecum.com/lots/LV0121-435629/1911-pierce-four-cylinder/

Maybe the tag didn’t work, just search Old Cars Weekly Golden Quill 2020 … dc