- Home

- About Us

- Join/Renew

- Member Benefits

- Member Pages

- Log In

- Help

- Museum Store

Thanks, it’s not concours but it will do for a driver. The dash is woodgrained metal per original. I had all the woodgrain bits redone several years ago by Undercover Paint and Upholstery for a very reasonable price.

The gauges are a bit mix and match. The amp and oil pressure are originals in very good condition that I found over the years that I basically did nothing to. The temp gauge is also original that a previous owner must have found that was in pretty good condition but the white on the facia is more browned from age than the rest. I don’t like redoing original stuff that is in pretty good condition but not perfect. Somewhat inspiring when things manage to survive 85 years and still look fairly good. I debated even yesterday on taking it out and redoing the facia, but I am paranoid about disturbing it any more than necessary. In the box of parts it was still sealed with K-S fluid but for some reason it seemed to have a bubble somewhere that screwed up the readings and I couldn’t get it corrected myself. Years ago I had “The Temperature Gauge Guy” replace the capillary tube and fluid to get it reading correctly again. I suspect it got screwed up by having it lay on its side in the box over the years, so I have kept it more or less upright since and it is the last gauge I installed in the cluster while hanging the dash vertically. Hopefully the whole mess will work

The speedometer face is glass with translucent white with black numbers painted on the back. That usually flakes off and this facia is a reproduction I was very luck to find. It had been done to restore another ’35 and a few extras were made. Before this I had created a complete CAD file to have one silk screened but finding this one saved me the trouble. If anyone needs one in future I still have the CAD file. Being fresh and new it is whiter than the others.

Being a DIY’er like you, I did the gas gauge and clock face using CAD and inkjet printing. Because the K-S fluid is corrosive and ruins fuel gauges over time I left the little top cover off in hopes it would reduce the trapping of KS fluid vapor in the gauge. Maybe a mistake.

The far left is non-authentic to replace the radio blank (my car did not have the optional radio and I feel like a radio blank makes it look like one cheaped out). It has an EGT and oil temp gauge I made from the innards of new gauges. I have bypassed the oil temp regulator/cooler since mine leaked and wanted to track oil temperatures. I have also been curious about exhaust temperatures for many years as it is an instigator for exhaust valve seat recession. The design matches the style for the most part of the oil pressure and amp gauges.

I’m not sure, I haven’t tried taking them apart as the springs and balls are swaged in permantly. I would have to drill the ends out, find some miniature springs and balls and probably drill and tap to hold them in with set screws. A lot of hassle for such a little part!

Dave, thanks for looking it up. The reference from the report server is below I didn’t know things went back that far but looks like it is in the 1964 Arrow issue #3! – before the PASB’s?

I forgot to mention mine is a 1935 845, but a ’33 836 is probably relevant if you have it.

The Arrow – Pressure, Oil Gauge – Tubing Replacement, 1933-

Subject(s):Motor, Lubrication system

Model:836, 1236, 1242, 1247

Cylinders:8

Publication Title:The Arrow

Publication Year:1964

Issue #:3

Page #:14

Here they are assembled, this is a ’35 but I think ’33 is the same.

Here they are assembled, this is a ’35 but I think ’33 is the same.

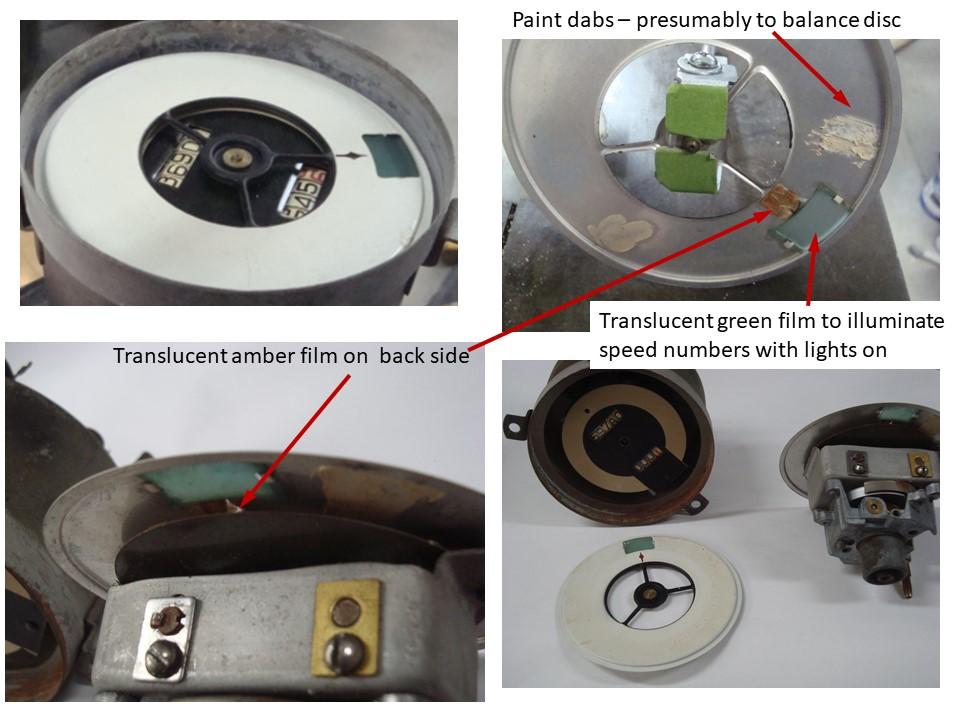

Ed thanks for responding, but I have 3 original ’35 original speedometers and 2 out of 3 had this amber colored translucent film cracked but still attached to the back. One was the original on my car and I don’t believe had been touched. On the 3rd the film was completely gone. There is nothing on the front side of any of my white discs. The arrow is a hole cut in the white disc and the indirect lighting from bulbs in back would illuminate the arrow from behind, and the larger green rectangle illuminates the speed numbers through the translucent front glass facia (not shown).

My question was probably a bit pointless, whether the original color was actually red but like the red KS fluid used in the fuel and temp gauges had turned to amber with age. It seems like red is a more obvious color -easier to see and matches the red arrow in the Pierce logo on the glass facia and the KS fluid. 85 years on there is probably no way to tell as all of them would have aged, unless there is some blurb in original literature describing the speedometer. I think ’35 was the only year to use this style? The arrow cutout is pretty small, and being translucent in the first place it is probably a bit hard to see in daylight, and it wouldn’t surprise me if some gauges had a black arrow put on top of the hole at some point to be able to see more clearly. Or maybe Pierce changed it late in the model year because of complaints. Right or wrong I redid mine with a translucent red film on the back. When reassembled I have to look pretty close to tell that it is actually red and not black in daylight without the backlighting.

The design is pretty interesting to me. All of my discs have rough splotches of beige paint in different spots on the back. I believe they were to add counterweight balance the disc. to Except for the paint blobs and translucent films the back side is natural aluminum and the fixed disc underneath was white. There are only very small cracks around the periphery to let the light get under the rotating disc, so reflective back and white is to help bounce the light into the into the narrow space to light up these small translucent bits. All the plastic windows for the indirect lighting on my other gauges are green.

to Except for the paint blobs and translucent films the back side is natural aluminum and the fixed disc underneath was white. There are only very small cracks around the periphery to let the light get under the rotating disc, so reflective back and white is to help bounce the light into the into the narrow space to light up these small translucent bits. All the plastic windows for the indirect lighting on my other gauges are green.

Jim

In the ’34-’35 the knuckle assemblies are listed as 704498. I don’t know how much 836A has to do with 836, but 836A is listed as 705051, and the notes indicate 836A had shorter steering knuckle arms 6 1/4″ center to center holes with 703216/703217 part numbers, but replacements should use the “latest type” used on 840/845 1240/1245 that are longer 7 1/8″, part numbers 704630/704631, so those should be interchangeable.

836A also used that same 704563 center axle. It appears that besides the steering knuckles the only difference in the 836A was different wheel bearings. The brake parts are all listed as the same part numbers between 836A and 840/845 1240/1245. For example the front right brake assembly is listed as 704604.

I am guessing that as long as the distance between left and right spring mount holes are the same that complete axle assemblies would interchange.

Jim

Bill, I don’t know if this helps. Trying to interpret the ’34-’35 parts book, the part number for the whole front axle assembly with brakes is 704613.

Something listed as “axle, center” is 704563. I am speculating that is the actual axle forging, but don’t know. If you have ’33 part numbers for specific items we could compare to the ’34-’35 parts.

Jim

Better late than never? I just refinished my faceplate and tried several alternatives to getting the raised art deco streamline patterns to show. I tried painting over the whole thing then tried to polish off the high spots with chrome polish and rubbing compound with a very flat dense foam block. The compounds wouldn’t remove the paint, at least not in any practical time frame. I then tried removing by slightly damping the foam block with lacquer thinner and carefully wiping along the lines – close but no cigar. I tried wiping with vaseline before painting to create a release coat, my hand wasn’t steady enough. I then tried masking with painters tape but being opaque and comparatively thick I couldn’t cut out the low spots with any accuracy.

What worked was using plain old cellophane scotchtape to mask.

The steps:

1) polish the streamlines with chrome polish. I found a Dremel helped initially but the chrome plate is so thin that it could take very little of that treatment before seeing copper. Most of it was done by hand with a rag. I think the dark brownish green color was actually anodize as lacquer thinner did not remove it, but the polishing step did.

2) mask over high spots with scotch tape. the scotch tape is clear and very thin and easily cuts with a fresh #11 X-acto blade. The edges of the raised lines are just thick enough to aid in the X-acto following the edge. Very tedious needing a steady hand and a magnifier if you don’t have near-sighted natural magni-vision like me. However, the process only took about an hour and a half once started.

3) Paint, let dry

4) remove tape – also tedious.

The whole process including unsuccessful experimentation took about three hours excepting a couple hours to let paint dry.

It is just a cheat to make it look like it woks. You cut a piece off the little red tube that comes strapped to a can of WD40 and drop it into the glass. You chose what level you want to see based on the length cut. Of course it doesn’t read fuel level but will stay red. Then you track miles on the odometer to refuel.

I haven’t given up and this round on KS has given me another idea to keep one working, but will be awhile before I have a driving car to try it out.

Similiar to Greg, I had the fluid in my KS gauge go from bright red to clear suddenly in a two week period after bring fine for several months. It was sitting in the garage out of the car after testing the system.

Y’all may recall that I started a test of KS fluid color loss a few years ago trying to figure out what was causing it. It is still a head scratcher. I put samples of fluid obtained from Classic and Exotic and Mac’s into glass vials. Some were exposed with only simple glass covers, others had UV blocking glass. After my nephew suggested it was likely a reaction with the copper in the tube and brass reservoir I dropped some copper and brass bits in new samples. Those turned from bright red to more brownish fairly quickly after, but not clear.

I had all the samples hanging outside my garage for a year and a half in the intense high desert sun. None of them turned clear, the red became darker. So it remains a mystery. The fluid I had in the gauge that suddenly did turn had been stored in its black light blocking bag but was about 15 years old when I finally took it out.

As Greg says the seal between sending unit and gauge is critical, but another piece of the puzzle is the sending unit in the tank which has very tiny holes and tiny tubes that must transport air bubbles down the tubes and under the air dome to recharge the air dome when the tank is sloshed around. If the holes are plugged it won’t recharge. On my sending unit the tiny hole under the air dome was blocked with fuel varnish. I say air bubbles, but in reality they are fuel vapor bubbles. I suspect that the reason the air line loses pressure even with a perfect seal after sitting for awhile is some of fuel vapor in the dome reliquifies. The repair instructions for the gauge say to remove the air tube connection at the gauge and backflow air to purge any liquid fuel in the airline that would cause erratic readings. I wondered how liquid fuel could even get into the line the way it is set up. I am thinking it is because it is not air, it is fuel vapor and fuel heated up on a hot day drive might condense in the tiny line. My theory of tbe moment.

Jim

The reason for the King Seally fluid is it is unusual in having a density about 3 times more than water, 4 times more than gasoline and makes it feasible. Basically this is a static manometer, if you used gasoline in the gauge and the difference in height in the tank between empty and full was 12″ you would need a 12″ high gauge in the instrument panel-well actually about 6 inch height based on the total difference in height when the level in the brass reservoir drops as it rises in the glass with a full tank. The amount it drops on the brass tube reservoir behind the glass is the calibration the little rods do.

I have toyed with the idea of leaving the little cap off above the glass tube and adding a small tube stuck in the tip of the glass to allow it to vent outside the gauge to prevent the corrosion. A bit worrisome because the fluid is toxic, but even in the gauge it isn’t sealed so any vapor would eventually leak out anyway. Presumeably the amounts are negligible.

Since I think the majority of guys seem to have given up on making this wacky gauge work anyway, you could dye a fluid and leave it disconnected, or use the WD40

red tube trick. I talked to some Ford guys who also give the advice that they can’t keep them working. I haven’t given up yet, but I also don’t have a car I can drive to get the experience.

The wires are to calibrate the gauge, if you get them out just make sure you put them back. The total crosssection and of the wires adjusts how much fluid drops in the brass reservoir and rises in the glass. It allows a standard gauge to be adjusted to different tank configurations of different cars.

I used lacquer thinner.

You might also look at McMaster Carr. I found good matches for both my trunk lid and upper door bulb seals.

Richard, welcome to the club. The 91 octane won’t be any more potent, ir just means it could tolerate a much higher compression ratio without knocking. The engine originally would have been running on something like 70 octane. The potential problem with 91 octane even if it is alcohol free is that it likely has more of the volatile petroleum fractions that can give vapor lock problems, which is also a problem with ethanol blends. Hard to predict, so regardless I would stay close to home in hot weather to see how it runs. Worst case is usually trying to restart and run after the car has been warmed up for awhile on a hot day then shut down for 10-30 minutes. This can be tested at home.

These cars were not perfectly symetrical, but the nail strips generally have enough give to work them on the car for final adjustments. Bending them on the plywood forms wasn’t a precision art. The leaded joints where the panels were welded together are a real mess.

The strips come 5 ft lengths, 2 per side. The curves are not constant radius, but I did mine with two templates, front and rear halves. The curvature was marked on paper laid on the top and transferred to the plywood.

I believe some have managed to form them in the car’s top channel itself, using the car as the tool to bend it.

Waldrons is a source that can make very long mufflets to order, however it took a very long time (months) to get one a few years ago for my ’35. A source for a couple of mine (’35 has three) was Summit racing online, which has a large selection that is sortable by diameter, length and construction.

Jim

David, I guess I am overthinking this, I spend a lot more time thinking how I am going to do stuff than it takes to actually do them, hence why it takes me so many years on one car.

Some sources for doing this say to predrill the nail strips before bending them, as it should be done on a drill press. This means the nail strip holes cannot be guaranteed to hit the oval holes in the sheet metal consistently after bending and trimming. I bent the nail strips first then marked the locations to drill the nail strips that would miss the sheet metal between the oval holes. I chose one of the Ford nail strips instead of the more “correct” solid oval strips partly because the pre drilling is on a flat surface instead of on top of a curve so it could be hand drilled after bending instead of a drill press. Snyders if I remember recommends about 1 1/2 inch spacing for nails in the nail strip, which on my car is every other oval hole in the sheet metal. Since the top insert material covers up the holes their location is blind while driving the tacks, so I am thinking I need to to have some marks outside the top fabric to indicate where the tacks can be put in that will not coincide with the nail strip nail locations. Basically I don’t see how one places tacks on one side of an oval hole that is covered up by the fabric while driving them except with some way of marking on the body outside of the fabric, or maybe on the fabric?

Thanks, it seemed like something like that must be used, I will look for it. I think I used a soft non curing caulking on my Packard 3 decades ago, but not sure. It seems like something rubbery, tacky, and a bit gooey would be ideal. The gooey rubber in dynamat sound insulation might be great if it weren’t for the aluminum backing on one side.

I have been fussing over how to do this, mainly concerned with how to make sure that the nails of the pre drilled nail strips don’t hit either the heads of the first tacks holding the top before the nail strip or the sheet metal between the holes in the body. I am thinking of making marks on tape on the body next to the nail strip as a guide for the tacks.

I have already bent the nail strips to fit the channels and pre drilled. I am still a few months from doing the top.

Thanks! Jim

Sorry to add more to this long thread, but perhaps some notes on the fire I mentioned might be apropos. On a hot summer day tour we stopped for a break and when one of the drivers tried to restart it would just crank and crank. Thinking it was vapor locked he turned the electric pump on and kept pumping and cranking. It probably flooded first from percolation from the carb bowl through the main jets and then the accelerator pump. Soon smoke started coming up and flames out the hood vents. Fuel was running down the carb and manifold. Quick action by members with fire extinguishers got it out with just damage to the hood.