- Home

- About Us

- Join/Renew

- Member Benefits

- Member Pages

- Log In

- Help

- Museum Store

It seems like there are a couple of advantages operationally for the 836A, it still had mechanical lifters instead of the hydraulic which can have issues, also no oil temperature regulator/cooler that is prone to leak, and a simple thermostat instead of a thermosylphon to control the shutters that are now pretty expensive to replace if they go bad which they sometimes do.

No louvers in the hood could be a problem for vapor lock, unless it is one that has thec1935 style hood with vent doors.

Noel, the reproduction of a Pierce dealer data book in the Arrow 95-2 lists the overall length of the 1255 147″ wheelbase as 18 ft 10 1/8 inches. The width over the fenders is 6 ft 1 and 1/4 inches. It notes this is for cars with rear spare, cars with sidemount spares average 2″ shorter.

Looking good. Are the winders you refer to just the springs, alone?

IMHO a beautiful color. I had well over 30 samples mixed adjusting to try to get to that look. Light yet still conservative. I didn’t quite get there, but at some point one has to move on.

Looks great! Hope you get the brakes sorted out. My first round with 4 wheel mechanical brakes were bad until I learned the sequence to tighten the shoes until they cinch the wheel then tighten all the cables as tight as feasible then back off each wheel to almost dragging. It was like rear wheel brakes only until then.

David, your guy at least got more respnse than me, answering with a few weeks which never came. My repeated inquiries via voice mail and email specifically asking whether the timeframe was in weeks, months or years brought no response except they would check with the owner and get back to me the next day which never happened. It would have been fine if they had just been upfront and admitted they didn’t know so I could act accordingly.

On the other hand Marcus at Heritage doing window shades was great, prompt with what he could and couldn’t do and how long it would take.

What a coincidence, there must be a story here!

Well… SMS turned out to be a very unhappy choice. They had a broadcloth sample very close to what I was after, the sample card said they had it, I ordered it and the following week I didn’t have a tracking number so contacted them. They then said it was two week minimum to ship. Three weeks went by and no response. Finally I got a response that they had to make the material – first time that was mentioned. Repeated emails and voice mails asking for some idea of time frame brought no answers. Tried Hirsch again, they had received some new stock in the meantime and I ordered from them. Had it the following week. Canceled my order from SMS who feigned ignorance, but finally got my refund posted today. A 3 month fiasco.

SMS may be the only source for custom fabrics but useful only if you don’t mind being treated like a mushroom and don’t need the material for a year or more. I am lucky to have gotten a refund based on the many BBB complaints.

Interesting. The normal pick up tube coming from above goes very close to the bottom so can still pick up crud but not as bad as it just dropping into a bottom hole. I din’t believe I could ever get my tank 100% clean without cutting it open, and on another car sloshed gas tank sealer which became a bigger problem than the crud. My ’60’s cars have a filter screen on the pick up tube, but of course on of the problems with a screen on a pickup tube mounted on top of the tank is getting it out to clean if it plugs up.

If my car ever comes back from the upholstery shop I have been thinking of modifying the fuel system. Normally it will use the original mechanical pump drawing from the original pickup tube, but the the auxiliary electric pump system will draw from the bottom drain fitting and have some recirculation up to the carb to cool fuel system and return hot fuel and vapor to the tank. This to fight vapor lock problems. It would return the excess fuel via the original pickup tube flowing in reverse to backflush the pickup tube. I think I can arrange a small vertical screen going up into the bottom drain fitting to keep the big chunks out and then a good sized transparent water separating filter to catch the fine particles before going to the electric. Being on the bottom the small diameter screen going up through the bottom is accessible to remove and clean and it is only operated occasionally when the electric is on. It will go several inches up into the tank so it still can get fueling the bottom of the screen gets plugged with crud. The idea being I have two redundant fuel pickups. How’s that for overkill? I am paranoid of an engine dying on a hot day sitting in the left turn traffic lane in heavy traffic with a 5500 lb car.

Do you have a picture? The standard lines on my 35 are basically 3 coming out the top through the fitting screwed on top that holds the King Seeley fuel gauge sending unit in the tank. Coming out of the top of that fitting is the fuel feed tube attaching to the 5/16 tubing going to the carb, the, the tube with a fitting to attach the tiny copper tube that goes up to the KS gauge on the dash, and a vent tube for the sending unit that bends back towards the tank is isn’t attached to anything. That’s 3. There is a fitting on top of the tank above the filler tube for a copper line that runs up to the top of the filler tube to allow the tank to be filled to the tip without an air lock. That’s the four I can think of, at least for my 35 sedan. Does yours have more than these?

<p style=”text-align: left;”>I am interested that your engine also has the rebated step. On mine I didn’t know if that was something cut in by an earlier rebuilder to keep the rings from hanging in the usual wear lip to get them out or put in at the factory originally for the same reason.</p>

I bought one from Dave Murray a couple years ago. Make sure to note whether it is LH or RH, the part number should be cast in.

A cautionary tale: someone like me might end up driving your car. Awhile back a friend of mine rented out his Buick Roadsmasher and a 50’s Packard to a small “indie” movie production for $75 each. He asked me to drive one of them down for him. The producer asked if we would like to be extras for $20 driving the cars as background, and could I drive anything? Full of over confidence, I said sure. Most of the cars had been left by their owners for the day. Instead of assigning me to the Packard I had just driven down I drew a ’53 Chevy pickup. No problem. Should be like a ’69 Toyota Landcruiser six I had driven. My friend was issued overalls to look like a mechanic but was to drive his nice Buick that was more like a manager’s car. I was issued a loud ‘50’s sports coat to drive the buckaroo pickup. Casting and costumes obviously a mystic art left to professionals.

After waiting around for a few hours and snarfing the buffet lunch the call finally came. The beat-up Chevy was parked a couple feet behind a nicely restored Hudson, and I had to back up ASAP so he could get out. When I got in, I realized I was in trouble. First, no starter button. Then I vaguely recalled that some cars had a foot pedal to engage the Bendix and starter. Got it going, whew! The traditional three-on-the-tree column shift wouldn’t engage in any gear, which is when I realized the mysterious extra lever coming out of the floor was an aftermarket Hurst shifter. It had no shift diagram. My first guess at reverse was wrong and I lurched another foot closer to the Hudson. My second guess was wrong, and now I was inches from his bumper. The third try was a charm and I got the heap going in the right direction.

The bunch of us then drove our cars up and down the same block over and over in a race track pattern as background to the street scene. Luckily the Chevy had a “necker” steering knob so flipping U-turns curb to curb without power steering was a breeze. I didn’t know if the movie was ever finished but a couple decades later I chanced upon it and discovered the scene I was in didn’t make the final cut. All that risk to the Hudson for nothing.

I think gangsters and bootleggers favored Cadilacs, Lincolns and mainly Ford V-8’s if they were concerned about out running the cops.

A Bugatti Atlantic coupe replica made from steel is quoted on the Oracle (internet) as taking 12000 manhours. That’s roughly 3 guys working full time for two years. At $75/hr (pick your all up labor rate) that would come to 900,000 of fabrication/assembly labor. It is a smaller car.

A rough rule of thumb is ~17 manhours per lb to build the 1st example or a one-off prototype aircraft from aluminum with formed and built-up structure. That doesn’t include manufacturing the engine and systems but does install them. Assuming 1000 lbs equivalent of Silver Arrow aluminum body to build would estimate out at 17000 manhours which seems ballparkish to the Bugatti example. That is 1.3 million at $75/hr. The Silver Arrow body was probably more like 2000 lbs of steel but the volume of material that would need to be formed might be roughly equivalent to a 1000 lbs of aluminum as a wild guesstimate.

Finding a donor chassis probably is a relatively small piece of the cost puzzle.

Using foam molds and fiberglass can be done for less, probably in the range of maybe 1/2 to 1/3. This of course is assuming everything is done on a professional write checks basis.

Maybe someone else has some better examples to work from, but I am guessing well north of 1 million.

I believe that project was being done by Andrew Berg, his contact info is available in the roster.

Condensers are problematic these days, a thread a few years back lists an Onan condenser that is the right capacitance and more reliable than typical ones sold at auto parts stores. A universal 6 volt coil should work fine.

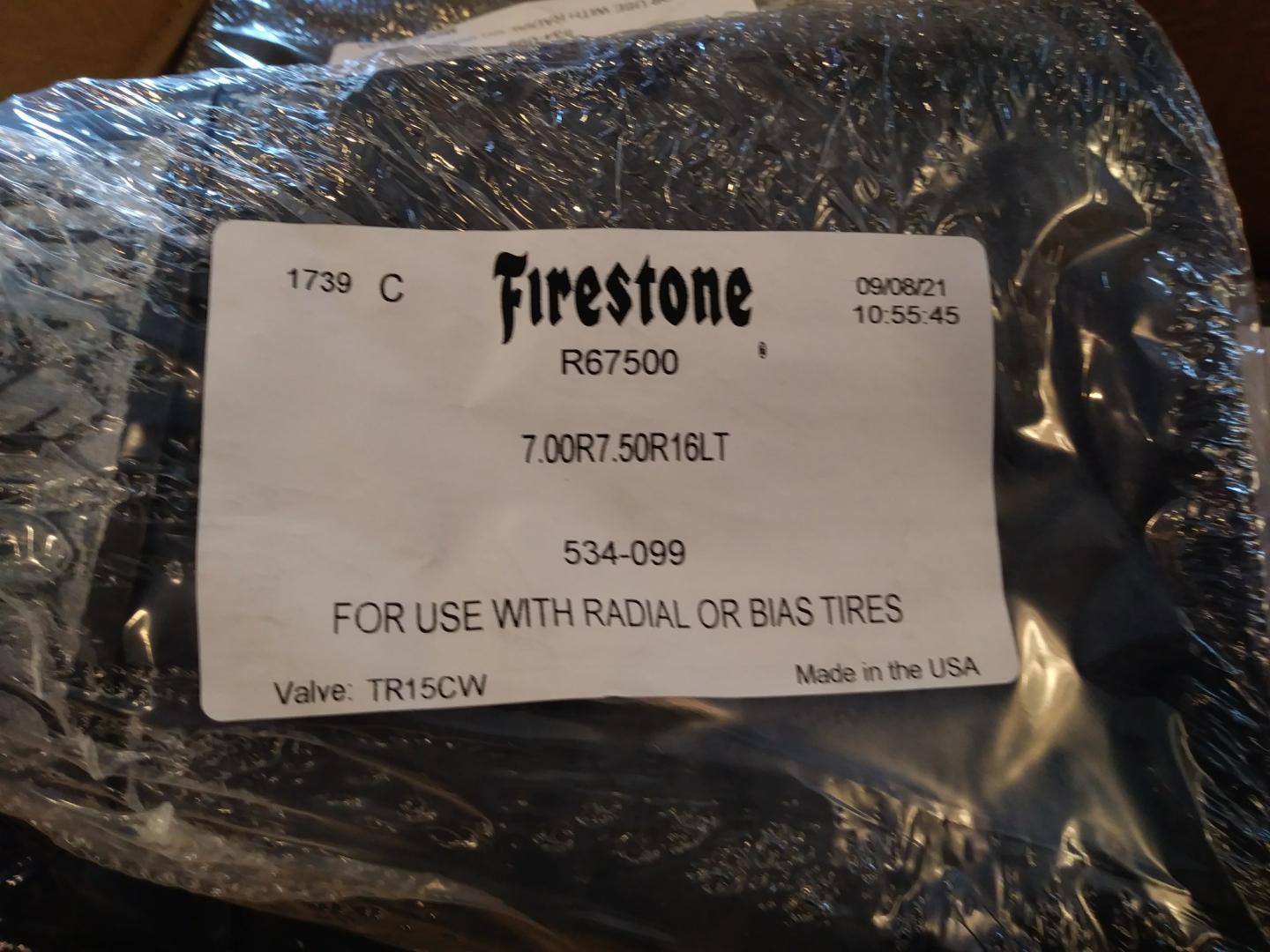

I just received them, see pic for part number. I confirmed they weigh over 3 lbs each instead of a bit over 2 lbs each listed for the imports. They are listed as having a 3/4″ valve stem offset which is what I measured on my wheels. The applications for what appears to be the same tube except for the smaller TR13 valve stem include some 17″ diameter wheels and there is some overlap in sizes with this one with the 5/8″ dia valve stem. Note their date of mfg was Sept 2021.

I have 700-17’s on back order, they are the same size used on my Packard (the car is sitting on old worn tires from the Packard) I also ordered tubes that should be here next week. Re-researching the tubes I discovered I probably ordered tubes that weren’t ideal for the Packard a few years ago, the valve stem offset wasn’t quite right and they were “import”. The thread from a few years ago on tube problems found that USA made tubes were a available, and luckily I found a USA tube in the Firestone catalog with proper offset and valve stem. The weight of that tube is stated to be about 50% heavier than the import, so likely it is a bit thicker and hopefully more robust. I ordered that specific firestone part number, hopefully it will be as stated.

Thanks Peter and David, SMS was a good lead. I have striped broadcloth material on the way, more expensive than Hirsch but I was having problems getting samples from Hirsch. Samples supposedly sent that never arrived and then not sending more after two weeks of waiting. I have had good service from them in the past but I think they are slammed with orders, and understaffed.

I removed my covers intact and reinstalled after disassembling the springs, cleaning and regreasing. I replaced the front main leafs due to corrosion concerns. The springs are wrapped in canvas before replacing the covers.

The covers are a very soft steel, tern plate I believe. I removed them one by one by getting a broad screwdriver under the joint to get them started then used a wide jaw vise grip to bend them back the rest of the way.