- Home

- About Us

- Join/Renew

- Member Benefits

- Member Pages

- Log In

- Help

- Museum Store

Looking good!

Thanks Peter, I have requested samples from them.

Jim

I switched to Hagerty a few years ago after being with Taylor for 30+ years. No claims, but after my local agent sold his brokerage it went to the local outlet of a big national firm that had no interest in the small potatoes of collector cars and would not respond to any of my requests for a simple change to add a car. Their local office was behind a locked door and would not respond to the telephone outside to try and gain admittance. Finally with a lot of telephone tag found someone somewhere (Iowa I think) at Taylor who made the change grudgingly. This did not fill me with confidence if I ever did need to make a claim.

When I became fed up I started looking at some of the other companies and the reviews for claims for most were very definitely not good. One has to take online reviews with a grain of salt of course as a few inevitable screwups will get the most reviews. Currently my local regular insurance broker will handle the Hagerty policy but I will have to deal with Hagerty direct for claims.

Consulting the oracle (internet) it seems it is a chenille or something akin to a chenille. The originals are out of town with the car at the upholsterers at the moment, they are looking at it as well. I’ll post when I learn something more.

I have contacted heritageaai.com who did a great job on my rear window shade. He also does assist straps and is probably my best bet.

I think I am in the final innings of a now 8 year restoration of a 1935 845 which is nearly the same car as 1934 840. I’m afraid I will have very few useable parts after the dust settles but lots of pictures and some experience. Many on the message board have much more Pierce experience and can help. David C. has been a big help to me. Parts and funds to buy them will be a major problem of course, significantly more challenging and expensive than ’50’s Packards.

No shop manuals, but one of the greatest assets of the PAS is 50 years of Service Bullitens that are now key word searchable and downloadable on the website.

The ’34-35 parts manual is sometimes useful and worthwhile but limited utility for interchange.

Good luck!

The only problems I have had on my cars myself are starting and running after a hot soak. My Pierce is not driving yet so I am trying to decide on an insurance system to install before the hood, fenders and runningboards go on making it much harder to to install. It could be I won’t need it but my tests so far indicate it is likely to be a problem. There are a couple basic ways I am aware for a recirculation bypass system, one is to just use an orifice at the carb inlet for the return line to bleed a fraction continuously of the basic mechanical fuel pump feed back to the tank to keep more circulation going through the pump and lines. This diverts some of the mechanical’s output unless an electric is boosting it.

I am thinking of a system,that uses the large excess of a rotary electric pump to recirculate only before and after briefly to cool the system and purge vapor after a hot soak. Most of the time it will operate normally on the mechanical without recirculation. It would be more effective as needed also for driving vapor lock. My original question was directed at trying to decide what a maximum pressure should be with the electric engaged. I think the answer is probably 1psi or so to make sure the electric doesn’t overwhelm the float valve in a hot carburetor and start overflowing.

Bill, I covered this in my articles on vapor lock a few years ago. Yes, the fuel line pressure has no influence on carburetor boiling. which is why a simple electric pump system doesn’t actually help with this. I am not a fan of insulation on the fuel line or the carburetor bowl to help with this, except for radiation shields with air gaps. The problem is that insulation slows down the transfer of heat but doesn’t stop it, so if a car heat soaks after a hot drive it will still heat up, just more slowly. Moreover, the insulation wrapped on a fuel line is going to absorb more heat radiating from a hot exhaust manifold than a shiny metal fuel line. The stagnant air under the hood rises to over 200 degrees for an extended time. When you get back in the car the insulation that slowed down the temperature rise of the carburetor bowl or fuel line now slows down how quickly it can cool down from the air that should start blowing around at around 130 degrees if you can get it going. The insulation’s effect of improving or exacerbating the problem becomes a question of how long the hot car sits before being restarted.

Dave, thanks. Interesting, they manage to miss 1935 845 but presumably it is supposed to be the same as 1934 with the 2 psi pressure, although just to add to the confusion the original mechanical pump on mine will pump to over 3 psi, which should be determined by the spring force of the fuel pump diaphragm.

My EE-3 with the original stainless steel needle (no rubber tip) resisted over 4 1/2 psi without apparent leakage to my surprise, but discretion being the better part of valor I will keep things at a lower pressure. 4 1/2 psi cold won’t be the same as when a hot carb bowl is boiling.

Several years ago I witnessed the percolation phenomena when I was testing the new radiator core in summer heat – no fenders or hood. When the engine was nearing vapor lock I found the left side idle mixture adjust screw had no effect, and peering trepidatiously down the carburetor I could see liquid fuel burping out of the main jet on that side from boiling. It would have been unpleasant if it had backfired at that moment. I am rethinking potential auxiliary electric pump system changes before the hood and fenders go on making changes inconvenient.

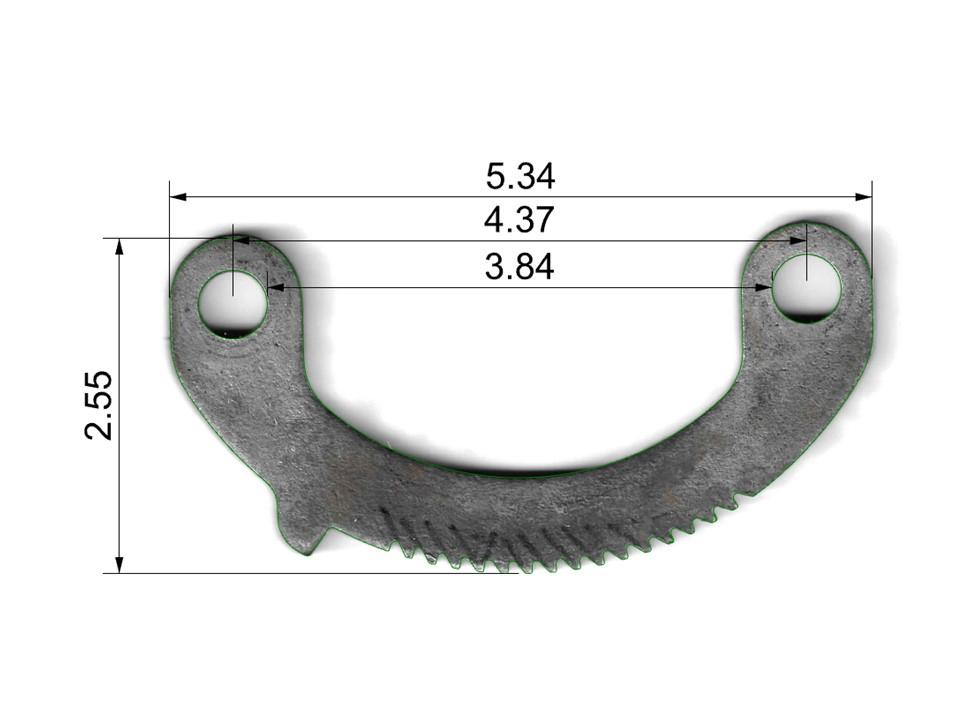

Here is a drawing/picture of the sector with some dimensions to check.

Tom, if you remove your original sector at some point and scan it and send it might serve as another example to try and divine the tooth profile more accurately. I don’t think it is very critical but having one installed will tell the tale.

I didn’t exactly modify the tooth angle, due to wear and possibly variations tooth to tooth of the original sector it wasn’t clear what the intended angle of the original was, so I erred on the side of keeping the pawl engaged without slipping out and disengaging. This may make it a bit harder to disengage, requiring more force pulling the handle back. I would try the new sector with original pawl first to see how it works since replacing the sector is a lot easier than replacing the pawl. I can modify the design if needed on a 2nd round.

I have had problems with worn park brake ratchets disengaging. A worrisome experience on those wine tours where you end up parked on a steep hill right behind someone else’s prize jewel. I carry wheel chocks now.

Good. I don’t know what else these might fit but I can confirm unsurprisingly that the sector does not fit ’35.

Joe, the picture of the pawl posted may be good enough to get an initial CAD design if you can give me a good dimension by calipers for the maximum overall length of the piece and the thickness to get a quick feasibility check for laser cutting.

Before actually getting anything made it will need to be removed and do a careful dimensional check – hole center to centers and diameters. I think I can match the pawl tooth geometry to match the sector Herb is sending.

Do we know what other years, series, models this fits? I don’t want to get too ahead of ourselves but would be useful to know if there is a wider need for this.

Herb, I can do the CAD design. 2 options. You can send me the part and I can turn it around back to you in a week. Option 2, if you have a printer scanner you can scan the flat image and send it as a JPEG. I would need some very accurate dimensions to scale the image in my CAD program, preferably the maximum overall length edge to edge, mount hole diameters, and of course thickness. Cheap printer scanners are amazingly accurate if you can get the scale nailed down. After sending the image I might ask for a couple other dimensions to verify. This looks like a pretty simple part to recreate the design.

This may be a good candidate for laser cutting or water jet. The laser jet company I use can cut up to 1/4 thick chrome moly steel and is very cost effective – generally much less expensive for single or short runs than machining if the part is a simple flat. The trick is creating a CAD file of the part to upload, which would need an original part or at least enough of an original piece to get the critical outer radius, teeth dimensions and attach hole location. It looks like a fairly simple part to design if an original is available.

It would be interesting to hear from the legal guys on this. I believe that trademarks may be limited to items that are very similiar and not widely different. For example, “Citation” is a Cessna brand for their business jets that didn’t stop Chevy from naming a car that. I think there are other products that use the name. Likewise, “Challenger” is the name of Bombardier’s (nee Canadair) business jet and also Dodge’s muscle car.

How does trademark square with the Pierce Arrow fire trucks that date back to the 1970’s?

That’s great! After all the discussion I am curious as to what was stuck to what, gasket to block, gasket to head, gasket torn apart?

Here’s another variation. Either use the spark plug holes or tap the passenger side stud holes to hold a size larger stud than the cylinder head studs that are removed. Put a hefty piece of wood several feet long stud with enough length to rest against the drivers side edge, A hole passing through the stud on the passenger side and most if the length hanging out on the passenger side. Probably one of these at the front and one at the rear stud locations to nimimize bending or twisting the head. This will give more leverage to peel. Assuming it doesn’t come up on its own, keep the load on it while you hammer in wedges between block and gasket. It seems like something that once a little bit of progress is made it will come up quickly. If the head ends up ruined hopefully someone has another somewhere?