- Home

- About Us

- Join/Renew

- Member Benefits

- Member Pages

- Log In

- Help

- Museum Store

Bill,

The flat helix around the upper end of the spring in your picture is a damper and yes, you need to keep it. The reason for the damper is to prevent the spring going into “resonance” and breaking when the engine speed is at that exactly wrong speed. I expect that earlier years had more broken valve springs than expected, so this damper was likely the Pierce factory fix for your car. Dampers are still used in some racing engines to prevent resonance vibration and float at high speeds. Search for “valve spring damper” and look at the images; same concept but the flat coil is now inside of the helical spring. After cleanup, put your damper back on the spring and install this combination in the same orientation as found during removal. This damper works by friction and should be slightly snug around the valve, enough to touch it, but not restrict spring movement. The idea is to change the natural frequency of the spring, but not change the spring force in either the valve open or closed position. Hope this helps. Herb

The good news is that you have saved one more Pierce from the scrap heap. It will be an interesting vehicle to see when you finish with it. Have fun with this project. See you at the next East Coast event. Herb

Bill, These pictures of your engine work look really good and show the progress you have made. So, congratulations! The tie wires are inside the oil pan and totally out of sight where nobody is ever going to inspect, so measuring twists with your eyeball is quite sufficient.

For us nut jobs who are REALLY hung up on having EXACTLY the recommended twist in tie wires, we first need our heads examined. However, if we still INSIST on verifying the pitch, there is an easy method. The UNC scale shows both 1-1/8 and 1-1/4 inch bolts using 7 threads per inch. Most thread gauges do have a blade for 7 threads (or twists) per inch, as well as many others.

Please keep us posted as your adventure progresses. Herb

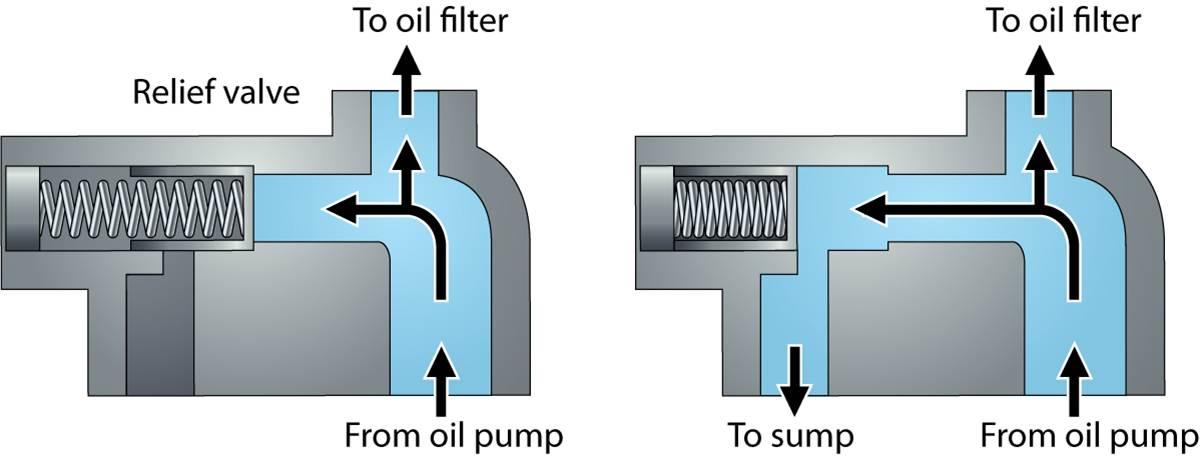

Randy, What would be the purpose of a grease fitting into the engine oil system? Is this a point listed on the lubrication chart? At best, the grease would dissolve into the oil and increase the viscosity slightly. If the grease remains in globs, it could clog oil passages inside the lifters or other small pathways in the pressure side of oil supply system. I expect it is more likely the threads in the relief valve body are for the tube fitting to the supply line for the “dirty” side of the oil filter. If the filter is mounted above the pump, then a check valve is needed to prevent dirty oil from flowing back into the engine when the car is shut down. What other device on the engine could provide this function? Modern replaceable oil filters do not have black flow if mounted below the normal oil level. Filters mounted above normal oil level do need a “flow back prevention” feature. Has anyone in the Society cut open one of these old style filters to see if there is an internal check valve? Regards, Herb

Bill,

Step #1 is to trace out your oil flow diagram to confirm what is going on. The rumor is that all Pierces with oil filters used a “bypass flow” type connection. If the bypass flow device is on the high pressure side of the relief valve, then this is likely to be the port that is the inlet to the filter. The reason for a check valve on such a device is to allow oil to flow up and through the filter when the engine is running. When the engine is off, this check should close to prevent the accumulated dirt in the filter from draining back into the engine. Pierce combined these two functions into one device, there should be a small ball as part of this check valve. Happy hunting for it.

Hope this drawing (from Pelican website) helps: Herb

John, With only one 6 volt coil in a 6 volt vehicle, no resister should be needed. Check the resistance of the primary coil, should be between 1.2 and 1.5 0hms. If the coil resistance is below about 1.2, it’s time to look for another coil. The “battery ignition” system should draw about 4 amps, so a 5 amp use should work in your fuse box, but a 10 amp fuse will be more reliable. Check your wire size and condition (new #18 is good for 10 amps, #16 can handle 13 amps. If the wire goes inside a conduit, use #16 – it will take more heat, then use a 10 amp fuse.). I strongly recommend using stranded wire, as solid wire will break from vibration – and that problem is difficult to detect and fix on the side of the road. Herb

John & Allen; I may have a fix for your resistor problem. I assume your ignitions are of the “two battery” type with no magneto. The ignition switch should look similar to the 0ne shown in the 1919 Owner’s Manual, where there is one ignition wire going into the switch and two coming out, one each headed for one of the coils. From what I have seen, most 6 volt coils have a resistance of about 1.2 to 1.5 ohms, using a current of 1.2 to 1.5 amps. Please check the resistance of your existing coils to verify that the primary is about 1.2 to 1.5 ohms. When the coils are in parallel, the effective resistance in that part of the circuit drops to about 0.7 ohms. If the target current of 4 amps is to be met, another source of resistance is needed to reach the total expected value of 1.5 ohms. For a target of 6 volts and 4 amps to each coil, an additional 0.8 ohms needs to be added to the single wire part of the circuit, BEFORE the ignitions switch. This location puts the resistor in series with the pair of parallel coils. This new resister will generate 25 watts and get HOT. Do NOT mount it on a wood panel. Use a 10 amp fuse in the block, then hide this resister somewhere under the hood – out of sight, but with plenty of air flow. This is what Chrysler did with most of their cars in the 1960’s.

There is a resister with 0.8 ohms at Summit Racing. It is from an MSD after-market ignition system. Part Number is: “MSD Ignition 8214” for $13.36 and shows to be in stock. It will keep voltage at each coil close to the nominal 6 volts. This value may not be exact, but will be better than nothing. Regards and stay warm, Herb

John, I looked in three sources and found 3 different answers for the 38 HP car battery ignition(?) circuit resister.

1) The PAS owner’s manual for C4 is a marked up version of the 1916 model C3. It shows the C3 with a volt meter in the ignition circuit, which will not read properly with a resister. No resister is shown in that diagram, but a pencil note “ammeter?” is in the text.

2) The PAS Wiring and Tune-up guide, from the Company Store (page 6, for Series 4 &5, 38 & 49 hp), does show a resister and an ammeter. It is a partial diagram, showing no ignition wiring, so no real clue where it fits in the full wiring system.

3) The PAS owner’s manual for a 38 hp car in 1919 has a wiring diagram with NO connections to space #1, so no resister. The Wiring and Tune-up Guide diagram agrees.

*If your car has only one battery ignition circuit using a 6 volt coil, and the other a magneto, then no resister is used. *If your car has a volt meter instead of an ammeter, then no resister is used. *If your car has two coils in parallel, then a resister may be useful, depending on effective resistance of the coils – but they should still operate OK for quite a while without a resister. If the coil has a nameplate showing the preferred voltage, then we can do the math for the level of resistance (ohms) and wattage (for heat dissipation) needed.

My only real experience with a ballast resister was a 1967 Plymouth during college years. That resister was a large ceramic thing that would be difficult to hide on your car. Web references discuss ballast resisters only when using a 6 volt coil in a 12 volt car. My ’29 does not have a ballast resister for either coil. I hope this helps. Best Regards, Herb

Jim,

Fuel delivery systems must satisfy two conditions: Zero demand before start-up and maximum demand on a long mountain grade. Gravity systems; vacuum tank or Ford Model A, can deliver fuel at nearly fixed pressure during all conditions. Mechanical pumps deliver fuel proportional to engine speed; very low during cranking and increasing with engine speed.

Electric pumps must meet both flow conditions with fixed output, often by using a regulator for pressure control. Too much pressure will flood if the float valve does not shut tight, but too little will starve the engine under heavy load.

The electric pump my ’29 PA uses has a separate switch under the dash – not direct to the ignition. Separate switches allow the engine to start with the fuel already in the float chamber. Then this switch is used to provide flow when running, or run it just a few seconds on a hot day to prevent vapor lock before cranking.

Setup of the carburetor will also have a large influence on the pressure needed or tolerated. If you want to dig deeper, send me an email. Herb

Joe,

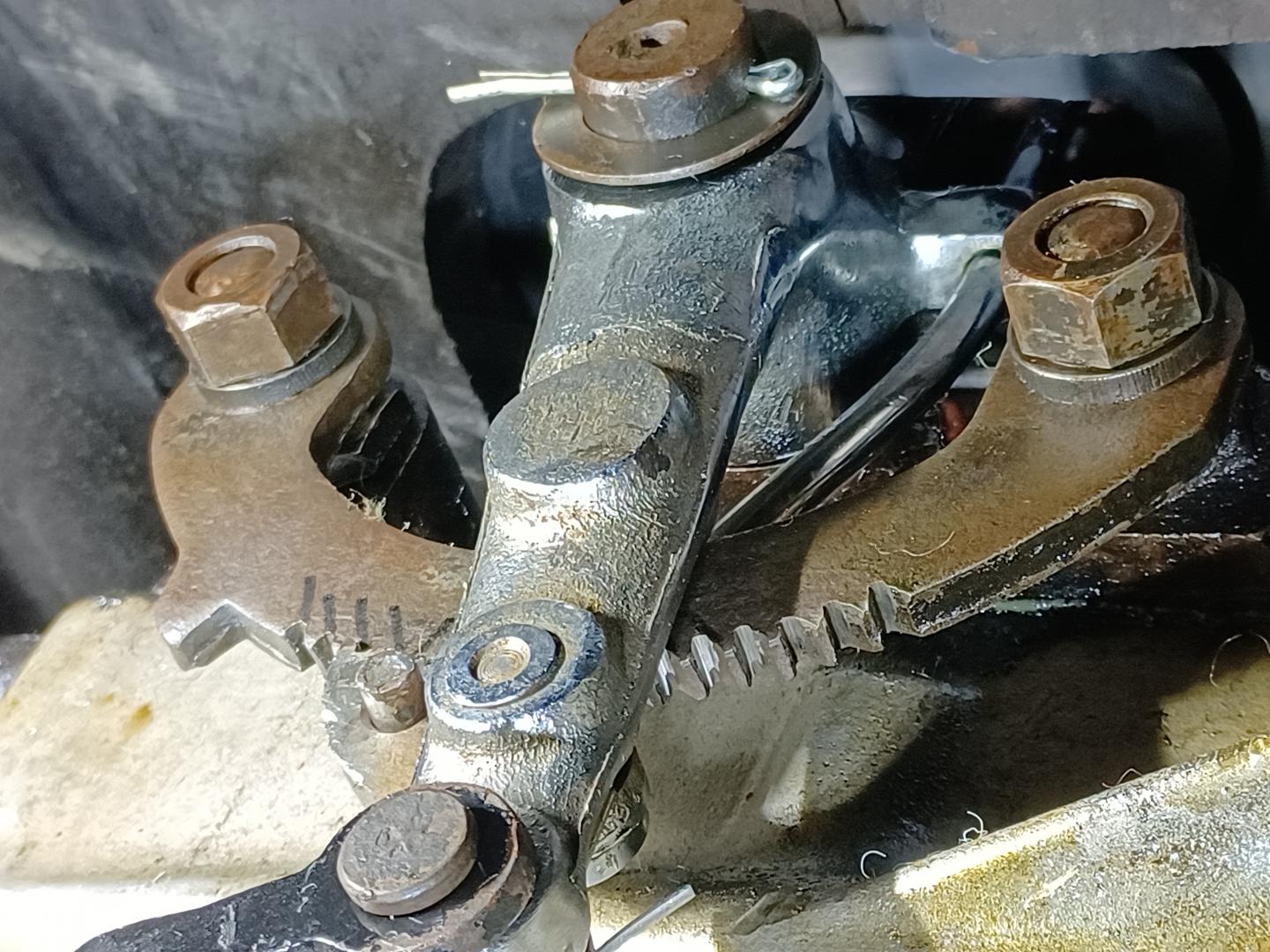

Yes, I do want one of the new sectors you are having made. When I purchased my Pierce, the hand brake did not hold at all, so I had to remove the sector and file to the teeth enough to make them at least functional; it works for now, but I do not trust it for long term use. The pawl appears to be in good shape, so I am reluctant to cut the rivet to replace it. Having a new sector with consistent teeth, rather than my amateur “dentistry” will be a very welcome improvement for a car that will be driven. Herb

The 1929 Pierce Arrow Parts Catalog proves its worth again. Page 18 shows the transmission and the view of the top shows the handbrake mount. The sector is noted as Part Number 123037, and is confirmed in the numerical parts list section. Joe’s reproductions are expected to fit models using this same part number. What hand brake sector are other models in this era using?

Joe,

The laser or water jet sounds like a very good fabrication method for this part. I don’t mind offering my sector for a limited time, but I was still hoping to get my car back on the road this fall.

(1) Do you anyone how can do the CAD drawing?

(2) How long would it take to copy mine before returning it?

(3) Can you please make several copies once the setup if finished? I would like a new replacement, and I suspect others would too. As our cars are mostly more than 90 years old and this is a (slow) wearing part, after this long, it will wear enough to be a bit unreliable and perhaps allow the car to sneak away. Herb.

Joe,

Joe,

Here is a picture if the parking brake sector that you seem to be missing. Here are some important notes: (1) The OUTSIDE radius with the teeth requires a circular radius to allow the pawl to rotate around the teeth properly, but the inside radius is support only and radius does not matter. (2) the teeth are NOT a standard gear form, but have a straight side so the pawl will not slide out and release the brake unintentionally (I found that surprise when I purchased my Pierce). (3) Find a original, as this part is a stamping and be difficult to machine – call Cislak. (4 ) Paint is probably optional as there is enough leaking oil to prevent rust. I have more pictures to email if you are interested. Herb

< sigh > Welcome to the wonderful world of Pierce Arrow, where you can get ANYTHING customized.

I can think of two explanations why the threads of these to caps are different: If Pierce made the parts in their factory as odd sizes, they made new taps to fit each radiator cap dimension. The more likely explanation is that the radiator and cap were purchased as sets, and Pierce changed vendors at some point between the production dates of these two cars.

Peter, you have a choice; since your dogbone threads match the radiator, it be made usable if you reduce the thread crest (OD of the threads) by about 3/32 of an inch, to match the outside thread of your existing cap. Then make sure the bottom of the threads of the new cap also fits the neck and use it ….. or keep using the cap you have now and let the dogbone find another home, as you mentioned in your first email. Thanks for the interesting problem, it was fun to chew on a while.

Peter & Dave, Based on Dave’s measurements, the nominal cap size is 2 inches; the next sizes are out of range at 2-1/4 and 1-15/16 inches. Peter, can you please measure (micrometer preferred) the outside diameter; top-to-top of the threads, in 4 locations around your new “dogbone” and check thread pitch with a thread gauge? Dave, could you also measure the threads pitch on your cap? Within the standardized UN thread series, the 2 inch size has several threads counts, each with different inside diameters and fits, which determines how tight the threads will be.

If both Peter’s new cap and Dave’s existing radiator cap have the same external thread diameter and pitch, then it may be possible that Peter’s new cap can be used on his car without trouble. Based on Dave’s neck inside measurement of 1.97 inches, I expect either 6 or 8 threads per inch, but please check and let me know (by email?). End of lecture.

Adam, the Chilton Interchange Parts Handbook 1927-1935 shows all 4 years PA’s using the Bendix “Duo Servo” type brake system. The 29 & 30 cars used the 3 shoe, 15 inch drum size. The 1931 models are listed as 15″ drum diameter and 2-1/4″ wide, but with 2 shoes. The 1932 models are shown to be 16″ diameter and 2-1/4″ wide, also with 2 shoes. You can verify the number of shoes in your car by jacking up the front and using a small flashlight to look into the drum inspection hole, counting the shoes as you revolve the drum. The drum inspection hole is very useful observing and setting the toe and heel shoe gap using a feeler gauge. My favorite brake reference book is “Vintage Veteran BRAKE Repair Manual” by Mr. C. Perham; (printed 1980) still having a limited availability on Amazon and should be priced about $30. Regards.

Jim, Let’s make a few assumptions here: 1) The head gasket has a copper surface in contact with the aluminum head and another copper contact with the cast iron block. 2) This assembly has probably been together for about 90 years in a hot environment. 3) No head gasket is perfectly tight, so some (conductive) coolant or exhaust gasses was between the gasket surfaces.

If these are true, you are now into the high-tech world of bi-metallic bonding. Search for “bimetal bonding” bonding between Aluminum/Copper and Copper/Iron surfaces bonds are known, some with commercial uses such as thermostats. After reading, don’t expect the Aluminum/Copper bond to break at all without machining the gasket away. Try to split between the copper gasket and the iron block. If the gasket has a compressible asbestos core, you may be able to cut it with a very thin hacksaw blade.

There is a discussion on reducing the Copper/Iron bond, but that chemistry is beyond me. Check the “BBC.UK/Bitesize” site for a good discussion of this topic, including suggestions on reversing the process. Regards, Herb

Randy, One book I strongly recommend is ” Vintage Veteran BRAKE Repair Manual” by C. Perham. It was published in 1980 and have found it very useful in setting up the brakes on my ’29. It also has a good section on relining brake bands and shoes and a discussion on adjusting series 80 & 81 cars. This book is available on Amazon (price not shown) and E-bay ($26.95). Internet searching does show several companies offering to reline brakes for antique / historical vehicles. I expect you could specify the friction material to these firms that you want used in this process. Herb

Dan, Sounds like you are on the correct path. Pierce used an “open” impeller, a style which does not develop as much thrust as most others. All impellers have thrust, trying to “climb” into the suction line, like a screw into a nut. However, the open side of these impellers allow some recirculation between the front face and housing, pushing back as a counter force to the suction thrust. The net result is very low levels of axial thrust. The washer you found is probably to hold the impeller in a fixed position, limiting the amount of recirculation to just balance these forces while maintaining pump efficiency. See you at Gilmore; Herb

Jason,

I expect there is another root cause to the short circuit problem than the ammeter itself; look for a bad wire or other power consuming device that has an accidental ground connection. I also use and recommend these three tools to help your search:

1) The Pierce Arrow Wiring and Tuneup Guide [on our website: Member Pages -> Company store -> Book Gallery ->(last row of books, on the right side)]. I have one of these books for sorting out wire problems on my ’29, and it is very useful.

2) A Voltage/continuity meter; to measure resistance to ground of individual wires and devices, you don’t need an expensive one. If you find something touching ground that should not be, then it becomes very high on the list of suspects.

3) Test Battery. I use the Rayovac #918, a 6 volt lantern battery with screw terminals to connect your test wires. This battery has enough juice to make many accurate tests – but not so much power it is likely to fry something else. The battery in the car has too many amps for testing, and is not good at testing individual wires or devices.

Happy Hunting, Herb