- Home

- About Us

- Join/Renew

- Member Benefits

- Member Pages

- Log In

- Help

- Museum Store

Where did you find the outside SS strips? Jim

Jak,

The pictures I lost are of removong the check balls and seats, I hadn’t posted them yet.

It seems like I’ve taken almost everything apart twice so it’s not a problem at this stage. Thanks anyway. Jim

Well somehow I lost the pictures and descriptions. I’ll take one of the fronts apart again and start over.

Arnold,

The front and rears appear to be the same internally and like the rears there ARE left and right shocks even though they will bolt up to either side. So you have to keep the parts to each shock together. Jim

Thanks, I’ll make sure to check those areas when the body goes back on.

Edgar,

What did you mean by upgrading the hinges? The hinge itself or the mounting fasteners? Jim

This is the tool kit that was in my 30 Mod B. I have the adjustable wrench it’s just not in the picture. For a 30 I don’t know if it is complete. Jim

If a 30 Mod B is the same I’ll send you a picture of mine. Jim

Is there any evidence of a sleeve on the deck surface? I wouldn’t want a sleeve installed from the bottom even if it was possible.

Are all cylinders like this?

If you are going to bore it .020″ over it would clean up anyway. Jim”

Thank you Pauls. Jim

Thanks Paul, I looked at ordering the set of 3 CDs of all the bulletins of the 70s,80s and 90s but I can’t find them on a order form. I must be missing them somewhere.

Chris I would appreciate it if you would send some reference pictures. I have a 1930 Mod B 5 pass 4 dr sedan. Thanks to you both Jim.

This car is like mine but much nicer condition, I have some questions maybe somebody can help with.

1.The ebay car has a burl wood dash panel and as best I can tell mine is straight grain, were there optional wood grain choices?

2.Is the amount of chrome on the engine and accessories correct or was that optional? Same with the interior, shift/brake levers?

I’m not wanting to overrestore. Thanks in advance. Jim Livings

Cal,

I thought I saw them on Lynn Steeles web site but they were under Cadillac I believe. I just looked and didn’t find them, maybe a call to Steele would help. I made a set for a L-29 Cord but they were a real hassle. Jim

Bill,

Thanks for the information. It confirms some of my speculations. If I ever do any more of these I need to make one of the fixtures.

It also looks like they couldn’t decide what fluid was best either.

Bill,

Yes I would like to have the scans. The only info I have is the patent pictures and the physical shocks I have taken apart. Thanks Jim

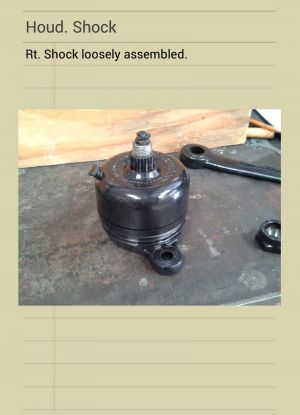

I decided to use hyd. jack oil, and the action after moving the arm to purge the air, the 2 I did seem to be working fine through the whole adjustment range. Definitely a single action shock and Lefts and Rights.

Roger,

Have you tried to clean the contacts in the switch you have? Open up the 2 metal tabs on one side and remove the back, clean the contacts with fine sand paper, wipe on a thin layer of Dielectric grease and put it back togeather. Jim

David,

Thanks for the side info on the antenna. I haven’t started on the body yet but noticed the ant. lead going up the RF pillar and didn’t know where it ended. Jim

Greg,

I assume that you already have the arm off.

Look at the lock ring and there are 2 or 4 round holes that don’t go all the way through the ring. I had both 2 and 4 on mine.

After using penetrating oil for 2 days use a 1/8″ punch and tap the ring at an angle in the holes to loosen it. If it won’t move I used a cutting torch to heat the ring gently and tapped again. I like the cutting torch better than the rosebud tip bucause the heated area is smaller, just don’t touch the cut lever. Don’t get the parts red, you just want to expand them a little.

After the lock ring is backed off a little I heat the reservoir the same way and use the vise grip chain pliers. They grip well and don’t damage the cover. The oil filter strap wrench might work, I just use the VG for anything odd shaped. Work the cover back and forth and when loose unscrew it all the way, if you don’t and let it cool down it wants to bind in the rust again.

Pay attention to the mating surface of the lock ring and you will see that it is tapered, when you reassemble do it the same way. 1 of my rear shocks looked like there was a thread sealer or caulk between the 2 pieces the other looked like tar. It looks like a #244 o ring would would work in that position but I don’t know if it would allow the ring to lock against the cover. When I get the shaft seals I might try the plumbers teflon thread sealing paste.

When you get that far the easy part is over..Any other questions just ask.

Jim

Before taking the shocks off the car I sugges that they be stamped for each corner and after taking off the nut, use a sharp chisel to stamp a witness line in the end of the shaft and the lever/arm.