- Home

- About Us

- Join/Renew

- Member Benefits

- Member Pages

- Log In

- Help

- Museum Store

We’re getting rainy sleet, Bob, if that makes sense. Mid 30’s temperature, so just imagine walking around outside in a layer of Slushee!

Forecast of low single digit temps Monday, my garage is heated by a heat pump and that won’t work well!

I agree, Luke.

What’s the saying, penny wise and dollar foolish? I occasionally have people ask me about fabrics from a local store, such as JoAnn’s, and I just shake my head.

They’re wanting to save hundreds of dollars on an upholstery job with $1000’s of dollars of labor.

A friend has a small restoration shop, and has a late 20’s Chrysler roadster he’s working on. Owner didn’t like what I said about cost for a new top, so he went to a guy who’s not familiar with early cars, but he was less than half the cost.

I went and looked at car, top not bad looking from a distance, then you look closely and the front to back top seams are backwards, and every lift-the-dot fastener is put on upside down. You CAN’T lift the dot!!

I’ve also had would-be customers want to use vinyl on a car that had leather, to save money (admittedly more substantial money), and I’ve refused to work on the car.

I never understand why cars are done in odd and cheap fabrics, when original style material is available. Fabric cost is the small percentage of total cost, labor is the same regardless of fabric.

No, interior in that car not original. Nice body style, has some issues I’m sure, will be interesting to see what it goes for…..

Ken, I wasn’t criticizing your posting, by the way, just commenting on the B-F usage!

Mark, welcome to the PAS, as I’ve told you in other correspondence anything I can do to help let me know, the Model 43 has a few quirks that other P-A’s don’t have!

Sounds like you got a good car at a fair price, congratulations…

Milt’s Pierce aside, I for one wish the phrase “barn find” could be eliminated from out vocabulary.

Not referencing this car, but:

A car put away in 1990, in a metal building with fluorescent lights, is in NO WAY a barn find. Yes, 26 years ago sounds impressive, but sheesh…

Richard, I would think you have the info on the 1903 Stanhope engine I own. Marked “Pierce 6”, it’s engine number 107. I’m told one can remove mounting bracket and there’s a car number stamped there, but have not done so yet.

Thanks Stu- my banker says that I didn’t win the lottery since last time it was for sale, so no go…oh well, someone will get a very nice car….

I bought the documents, mostly because of the nice letterheads from the Foss Hughes company.

In my Pierce memorabilia collection, I favor “hard” objects, but also have a collection of letterheads from various dealers and the factory.

Foss Hughes was a significant dealer, and I have numerous objects from that dealership.

“I only collect cars I like, but I like most all cars”….or something like that, good line from video.

I’m not familiar, personally, with car, but have seen pictures of engine compartment and there are a lot of visible issues under there… I also think the auction house statement that only 3 of this body style exist is wrong…

Haartz cloth is available from Bill Hirsch Auto Parts and LeBaron Bonnie. Many wholesale upholstery outlets sell it, too.

I actually had one wholesaler quote a price per yard higher than Hirsch cost….

So, with 5 under the top, it’s not a convertible coupe, but rather a Victoria with a rear seat?

I was never aware that Pierce bodied a ’36 in that manner. Interesting….

Sad to hear it was lost….

Picture didn’t post, oh well.

As to the replicated Pantasote, if you go that route, talk to Eric Haartz directly. He’s very helpful and deals in the oddball stuff, he does NOT directly sell Haartz/Stayfast, but does directly sell many early special materials.

Thanks, but I’m no authority.

A Pantasote type material was what was used. This was a woven cloth base, coated on the outside surface with a waterproof material. It was the precursor to modern day vinyl, which is exactly that construction, differing only in the waterproof material used.

Eric Haartz provides what is referred to as a “replicated Pantasote”, which is basically a vinyl material that’s had varied imprinted surface textures applied. It also has varied base materials, and the inner layer’s appearance varies from solid colors to a whipcord finish, which is striped.

So, long story short, you cannot buy today the exact original material as would have been found on a 1919 Pierce. Either go with a replicated Pantasote, or go with the well known Haartz/STayfast material.

Either way, my advice is to go with an inside color that is light, to brighten up the interior of the when top is up.

Eric did a special custom job for me a few years back, taking 40 yards of replicated Pantasote with whipcord backing, “melting” the heavy grain and putting more of an original style pattern on it. It’s still vinyl, but it came out great on the four cars that now have it, and enough for one more car (mine!). Shown is 1907 Autocar top, two identical ones I did and were the reason for the custom material, as we had a beautiful original top to copy.

My 37 Cord phaeton has an antenna cleverly hidden….hanging under the car!

As to the chicken wire antenna, it would be a single wire for AM, correct? Not a coax cable….

I’m familiar with Mel, decent hides for the price, I’d be willing to bet he gets his horsehair from Wohl’s. Very few suppliers of some original materials left out there….

Wohl in Philadelphia. Recently bought 10 pounds, it’s about $24 a pound….F.P Wohl 215-9345966….

Print close up 2

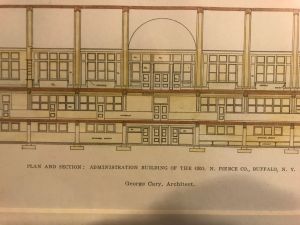

Print close up 1

As an aside, and this may be common knowledge:

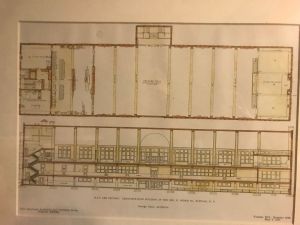

Kahn designed the Pierce Arrow factory buildings, but he did not design the administrative office building.

That architect was George Cary, a local Buffalo resident.

I have a few prints that show the design for the building, published in “The American Architect and Building News””. They are very interesting and show in detail the design features of the building.”

The ground wire in these cars was originally a solid bare copper wire, while an end connection might corrode, it’s hard to think that the solid wire itself would suffer.

I once put an insert in a 1932 Brougham, and it too had a charred roof! Once I removed the old top, it was nothing but black charcoal holding the top up. Only thing we could figure was the dome light shorted and the wood just smoldered, never really flaming.