- Home

- About Us

- Join/Renew

- Member Benefits

- Member Pages

- Log In

- Help

- Museum Store

I bought mine at McMaster Carr, it fit well. I have to do sa little digging to find the part number.

Thanks George. It looks like I found the relay in my boxes of parts, I had mislabeled it in my spreadsheet not knowing what it was for. Some things become more clear as the boxes of parts slowly get emptied and mounted on the car.

I see where it was screwed to the front splash pan, it looks like it was facing up above the pan rather than below it. A bit worrisome getting to it to disconnect if it sticks on.

I just got the hoods installed. What a delicate operation that is to raise and lower without scratching things up.

Its great he is still at it!

When I was doing research on chrome rings I ran across some interesting information from Perfect Circle. A coolant temperarure of 160 or less tended to “chill” the oil on the cylinder walls and leads to excessive coking, deposits and wear. Also the ’37 senior Packards offered higher temp range thermosylphons. Since overheating is happening when the temp goes above 200 I figured it didn’t matter from an overheating standpoint, once the temp reaches 180 the shutters are fully open at that point, it just means it gets past 180 a little sooner.

The 180 sylphon has been in my Packard for 15+ years. A side benefit is I have a heater and the higher water temp makes a big difference, except when going downhill and idling!

I set up the Packard for a lot of driving when I was younger with a lot more miles in front of me. I haven’t haven’t had the Pierce sylphon modified, although if I get one rebuilt I probably would.

I had one rebuilt and modified to 180 degrees instead of 160 probably 15+ years ago by James Otto of Knoxville TN. I suspect he is no longer in the biz.

Hirsch is selling them for 595!

I don’t know if the guy who was rebuilding them is still doing it.

I guess I have answered my own question. I went ahead and gingerly tightened all the bolts and despite the big compression load on the castings so far they didn’t break, didn’t crack the new paint, and the fenders and radiator shell lined up more or less like they must have originally. Fingers crossed.

Just a thought to clarify, the turn signal lights do not come on at all as opposed to coming on but not blinking off?

I think the LEDS can draw so little current they might not heat the flasher enough to disconnect and blink.

It looks like the 535 flasher is simple thermal relay and is used on a lot of positive ground 6 V. I don’t think the case is grounded, that can be double checked quickly with a continuity or ohmeter going from case to the 3 different leads. The x lead is power in, and I don’t think it cares whether it is + or minus. The X lead will be from battery whether + or -. The L load terminal is to the switch and then the lights. The P lead is “pilot” to the indicator light which may be a clue to the problem. The switch case is required to be grounded which might be the problem. I would try it with the P lead disconnected from the flasher.

Then I would check the flasher. Bypass the switch and connect a turn signal light with the bat connection to the X terminal and the light bulb wire directly to the L terminal. If that doesnt work you can try reversing the flasher terminal connections but I dont think it will make a difference. If that doesn’t work you might have a defective flasher.

Years ago I looked at these aftermarket turn signal kits and was “turned off” by how large clunky, and expensive they are. That big switch needs to be nothing nothing more than a simple double pole double throw toggle switch. I bent up a small aluminum can to cover it and strap it to the column. I added a little LED pea light sticking out of the case for an indicator. Much less obtrusive. You only need a two prong flasher unit.

I believe it was gloss, even though it highlights every defect.

What is the wiring going though the flasher? Is it just two wires going from the hot lead through the switch to the turn bulbs? Or does it have more wires and/or a grounded case?

If it is a simple magnetic coil switch polarity shouldn’t matter and perhaps the flasher Is defective. If it is solid state electronics then polarity could matter and it probably makes a difference whether the flasher is between the hot lead and the turn signal switch or if it is between the turn signal switch and the bulbs and has multiple leads.

Thanks Paul, sounds like the same as mine so it must be original.

Thanks George, I should bore with some caveats. I drafted an article about this a few years ago trying to have definitive claims and recommendations but as I reviewed the technical papers it becomes as confusing as the whipsaw of claims about diet and fat, carbs, salt, caffeine etc. There quickly become too many factors for simple answers.

The Harrison radiator engineer who designed and promoted the water cooled temperature regulator/cooler put on Pierce-Arrow’s from ’33 up with the hydraulic lifters has plots of how hot the oil gets when the RPM’s increased in the ’30’s. Senior Packards also had that unit and years ago I put some peak temperature indicators on the inlet and outlet of my Packard’s cooler. After a tour going down I5 at 65 mph in the summer heat the templaques showed the same temperature in and out, i.e. the cooler wasn’t cooling. However, the caveat of that is I have a very steep 3:58 rear end replacing the factory 4:69 keeping the engine RPM down to around 2600 instead of 3400. It may have been a different story with the original ratio. And as mentioned before, another paper indicates oil cooling isn’t that effective anyway by the time the oil reaches the con rod. On my Pierce I have the original rear end ratio and my oil cooler core leaks. I bypassed it internally, but with multi vis oil it shouldn’t be needed. I installed an oil temperature gauge to track the temps out of curiosity, although I probably won’t be cruising it at 65 much.

That Harrison paper was pointing out that various babbitts lose a lot of strength as temperatures go over 200 degrees.

However, Stanwood Sparrow, a Studebakar engineer, wrote two very comprehensive papers about improving engines to run at higher RPM. Much of his testing was done on dynomometers over 4000 RPM at wide open throttle. In this period the transition from poured babbitt con rod bearings to steel backed copper lead inserts was happening. Disputing the notion that high temperatures and high RPM were necessarily the cause of babbit con rod bearing failures he ran babbitt bearings without serious failure with oil inlet temperatures heated to 300 degrees. He pointed out a number of factors in bearing failures, one of the worrisome ones being a slight contamination of babbitt with copper.

Unequal clearance along the length of the bearings due to inaccuracies in bearing fit, deflection of the rod or crank, and too tight of clearances can be big problems.

Too many variables!

KY jelly, who’d of thunk? Stifling the crude comments!

Thanks, Jim

Personally, I never use straight weight oil.

The temperature of the oil when it reaches the critical parts of the engine is going to be hotter than the average bulk temperature sitting in the oil pan. The bulk temperature in the pan is just a very rough indicator of how much hotter the oil will be by the time it hits the bearings and cylinder surfaces. As it gets thrashed flowing through the oil pump, then flows through tiny passages in the crankcase and crankshaft it gets heated up. Then the oil emerges into the main or con rod bearings where it is heated up some more, then gets splashed or squirted up to the cylinder walls. At the top of the cylinder the wall temperatures get over 500 degrees, which is why oil cokes up there. The oil has a chance to cool down from its peak temperatures when it drips back down the cooler (less hot) crankcase and back into the pan. It is cooled further by the oil pan surface which will be cooler than the bulk temperature.

I have an old SAE report where the connecting rod temperatures were measured with various cooling schemes and it was noted that the majority of oil cooling took place by conduction from the crankcase then via the engine compartment air. Interestingly, an oil cooler didn’t have much impact on reducing the con rod temperature due to the heat gain of the oil passing through the crankcase and crankshaft galleys before it got to the bearings.

There are three basic critical design points for the engine’s lubrication.

1) Very low RPM at high throttle (lugging the engine) with very hot thin oil. Here is the most likely point for bearings, pistons, and rings to start scraping. When a hot engine is suddenly brought to idle after a hot drive on the highway the oil flow drops drastically and the oil left on the hot surfaces will heat soak and reduce the viscosity at the same time the sliding velocities are cut. The ability of the oil to keep film lubrication is a function of its viscosity, the loads, and the sliding velocities. The Pierce 66 with a 7” stroke has about the same sliding velocities at 1500 RPM as a 5” stroke Eight has at 2100 rpm.

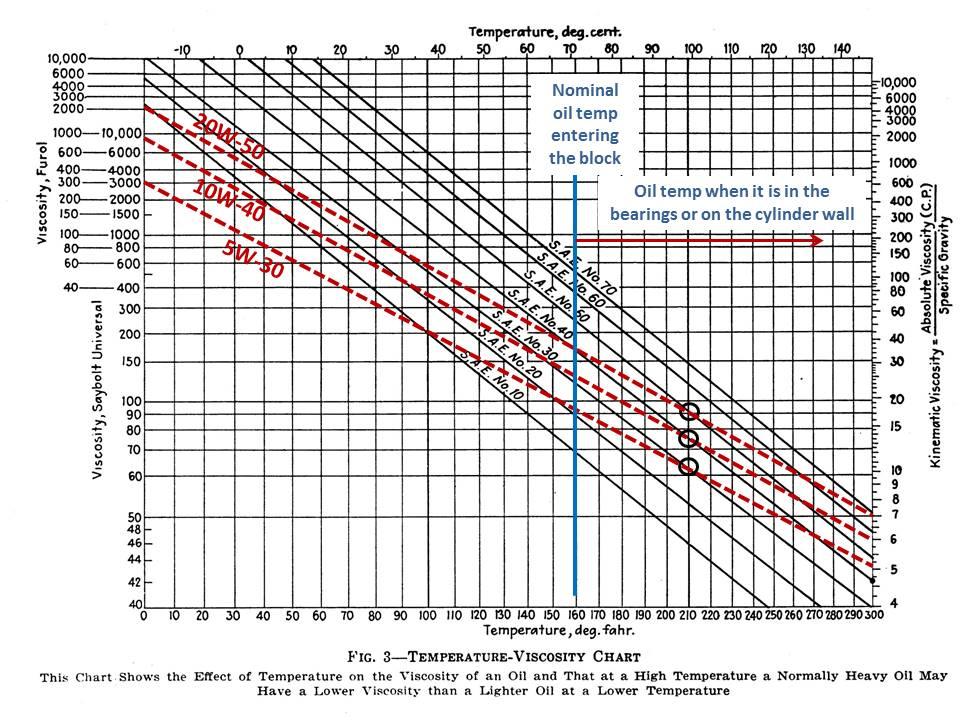

At peak temperatures on the bearing surfaces and cylinder walls above 210F a multi vis oil should be slightly thicker than a straight weight and give a bit more margin before film breakdown. The average temperature of the oil before it hits the hottest surfaces will be less though and a multi viscosity will be thinner and generate a bit less heat in the first place.

2) High RPM increases oil temperatures. Here there are large margins for basic film lubrication because of the high sliding velocities but the high local temperatures and rapidly oscillating forces can fatigue the bearing – particularly thick babbitt that weakens at high temperatures. The average temperature closer to 160F running through the engine is going to be less friction and will heat the oil up less when it reaches the bearings and cylinder walls, but when it gets hotter it will have a bit more margin.

3) Cold temperatures where the oil is thick, creates a lot of drag and reduces the oil flow in the engine when started cold. It was noted back then that cold oil could be so viscous that it wouldn’t even enter the pump.

In the end it shouldn’t be too critical. These engines ran fine on the oils then recommended. Modern oils are less prone to foaming which arguably was a bigger factor than viscosity in vintage engines. Multi-vis means you don’t have to worry about changing oil for summer versus winter. Note Packard recommended 40 weight for sustained summer temperatures above 90F whereas Pierce recommended nothing greater than 30 in 1935. A 30 weight multi vis like 10W-30 or 5W-30 gives a little more viscosity at high temperatures than straight 30 while having less friction overall. A 10W-40 will be a bit thicker and run slightly hotter, but much of that is mitigated by the reduction in viscosity with temperature. In other words, the thicker oil will get a little hotter which will make it a bit thinner, which reduces how much hotter and thinner it will get, so it is a bit of a dog chasing its tail.

I’m afraid when I had the same issue it was the floto screen plugged.

Multi vis is good, the oil cooler / temperature regulator was basically a substitute for not having multi viscosity oils yet and the hydraulic tappets needed to reduce the wide swings of viscosity with temperature. Pierce recommended nothing thicker than straight 30 in the summer. 5w-30 gets thicker than 30 above an oil temperature of 210F which occurs in the bearings and on the cylinder walls where lubrication is most important. 10W-40 could be used if you have problems with tappets at low speed, but it will increase engine friction and and oil temperatures a slightly.

Here is a chart I where I superimposed the approximate variation of viscosity with temperature. Note the extremely non linear change in viscosity with temperature for all oils. It changes by factors around 50/1 between normal starting temperatures and what the cylinder walls see on the road.

If you haven’t been before you could do a sidetrip up to Shelby, a bit north of Detroit, and take in the Packard Proving Grounds museum.

Thanks for the response! The Buelton meet provided the opportunity to see one solution to the question of how to deal with the inside corner which seems like the best. Cut the thick extruded runningboard rubber along the inside corner and apply a thinner rubber strip that can bend into the corner with an overlap that covers the cut.

You probably already know but the last known owner in the PAS directory is J. P. Van de Bundt as of 2005 whose membership is listed as expired. The roster lists the engine number as 201367 from a 30B and the serial number was missing.

I continue to assemble bits onto my ’35 and digging out repro parts from Irv I bought over 25 years ago complete with his notes in very tiny handwriting.

It seems like there are a couple of advantages operationally for the 836A, it still had mechanical lifters instead of the hydraulic which can have issues, also no oil temperature regulator/cooler that is prone to leak, and a simple thermostat instead of a thermosylphon to control the shutters that are now pretty expensive to replace if they go bad which they sometimes do.

No louvers in the hood could be a problem for vapor lock, unless it is one that has thec1935 style hood with vent doors.

Noel, the reproduction of a Pierce dealer data book in the Arrow 95-2 lists the overall length of the 1255 147″ wheelbase as 18 ft 10 1/8 inches. The width over the fenders is 6 ft 1 and 1/4 inches. It notes this is for cars with rear spare, cars with sidemount spares average 2″ shorter.