- Home

- About Us

- Join/Renew

- Member Benefits

- Member Pages

- Log In

- Help

- Museum Store

Bob,

I talked to some members that have more knowledge on the 8 cyl and they said that on the ’32 the whole filter canister has to be changed. At one time there were some replacement filters made that had replaceable elements. You might check with John Cislak, 413/543-9017, he is the most likely person to have one or know of one.

As far as the detergent vs. non detergent, that is a choice you will have to make. If there is no sludge in the engine, I would go with detergent.

Dave

Bob,

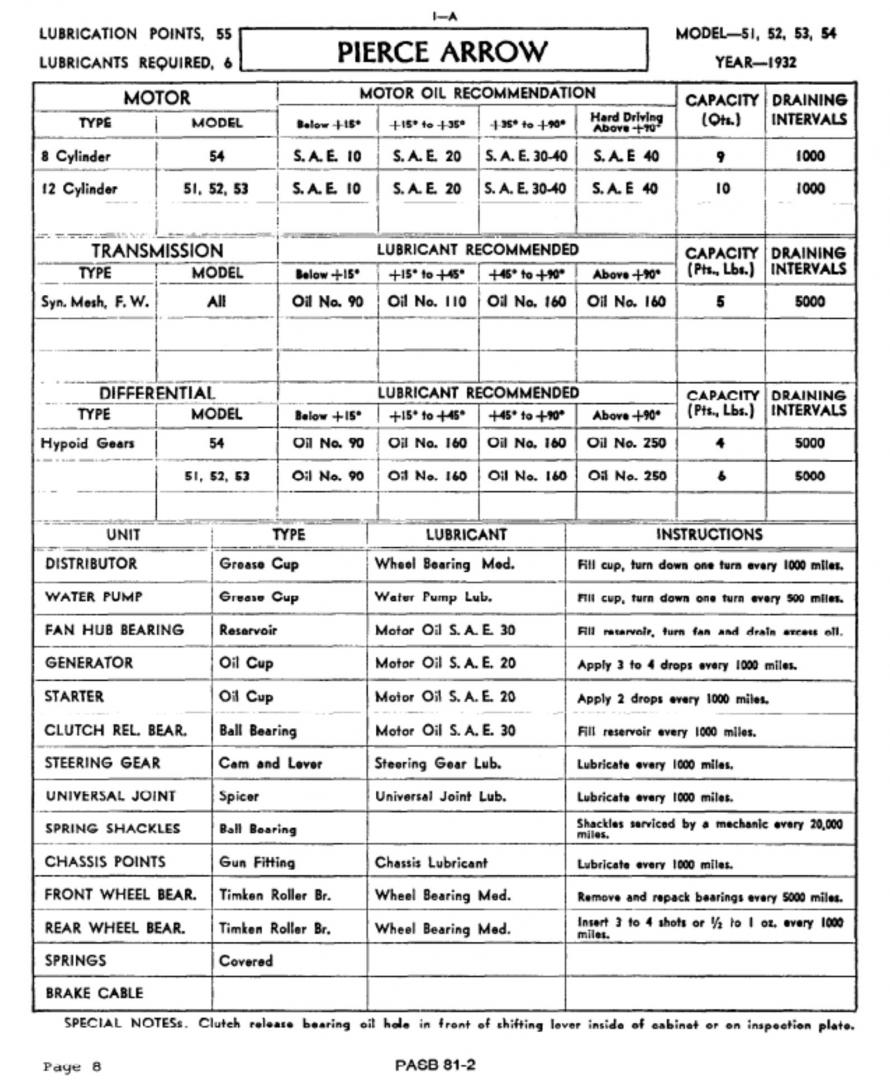

Asking “What is the best oil” is a good way to open a can of worms. Generally, most oil today is better than anything available back in the day. The chart below (and the Owners Manual) recommends SAE 30 for normal warm weather driving and 20 for winter and 40 for hot weather. A good Multi grade such as 10-30 will also be OK. Some people use certain Delo or Shell Rotella 15-40. These are Diesel oils, but also are rated for gasoline engines and are available in bulk (cheaper).

One of the controversial issues with oil is whether to use Detergent or Non detergent. If the prior owner has been using detergent oil, or the engine doesn’t have a lot of miles, I would recommend continuing to use it. If the engine has a lot of miles and has built up sludge, many people suggest a non detergent oil as there is some concern that detergent oil may loosen deposits and block oil passages. I have not seen this, but others say they have. You will have to make your own choice. Pulling the oil pan on a new to you car is a good idea as you can check the internal condition of the engine and determine if there is any sludge. Detergent oil suspends particulate in the oil for the oil filter to remove. Non detergent oil lets the particulate drop out and settle in the engine forming sludge. Your engine has a partial flow filter (the canister at the left front of the engine).

The other controversy with oil is the amount of ZDDP (Zinc / Phosphorus ). Newer oils have less ZDDP because it damages catalytic converters, but they still contain some. ZDDP was not added to oil until the 1940s, so when your car was new no oil had it. There is some evidence that lack of ZDDP may cause cam/lifter damage, but this is in high compression or newly overhauled engines. Modern oils have a number of anti wear additives that older oils do not.

I would suggest if you have concerns about either of these topics, you do some internet research on them. Just make sure the opinion you are reading is backed up with actual evidence, not that “My friend’s uncle says that….. ”

Not owning an 8 cylinder car, I don’t know what modern filter will work. Hopefully someone else can chime in.

You can search all of the Service Bulletins using the Technical Search tool under the Publications tab in the Members pages. It takes a little practice to get the search terms right, but usually you can get results to questions.

Service Bulletin 1995-6 (available under Publications) has an article on oil filters for early 8s. A clearer copy of the chart below is in Service Bulletin 1981-2.

Dave

Calvin,

You might check with John Cislak. I pretty sure at one point he had them.

Dave

Bob,

Do you have an Owners Manual for that car? They contain a lot of information about the operation and care of the car. A digital download is available under publications. https://pierce-arrow.org/members/owners-manuals/

Bob,

You might try contacting Dennis Egan who is looking for an 8 cylinder Pierce-Arrow.

https://pierce-arrow.org/acadp_listings/wanted-1928-1938-eight/

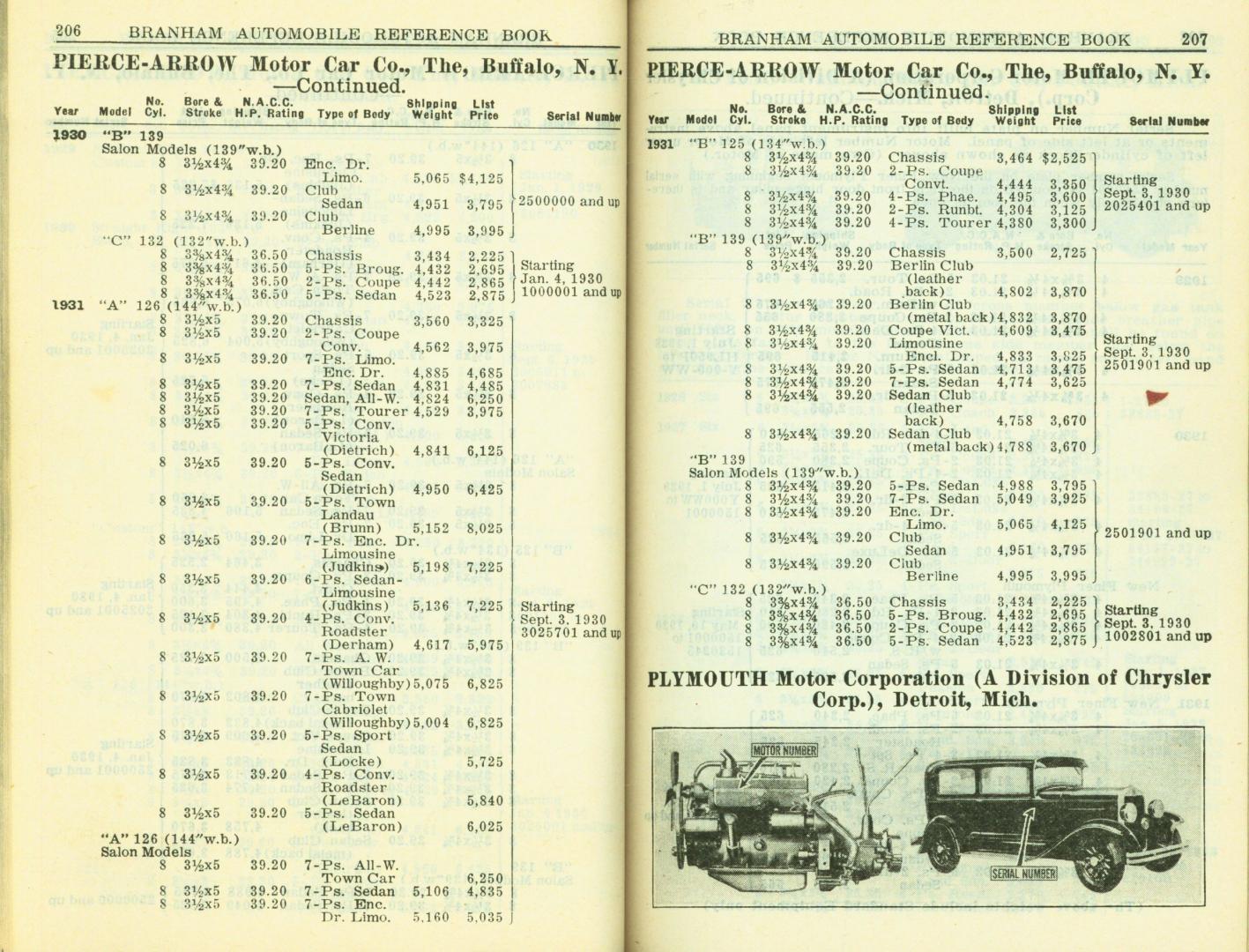

Branham pages that Brooks was referencing. As this is a jpg file, it should be loaded as an image.

Brooks,

If you email them to me as attachments, I will see if I can post them. Also, there is a 1931 Phaeton right hand drive currently in France. It doesn’t look like a salon model.

Ken,

Have checked with Greg Long. both about finding a radiator and whether the S 80 and S81 are interchangeable?

Dave

Alan,

Wire wheels are listed as an option for $90 for rear mount spare. $225 for cars including side mounts and a trunk rack. I don’t know about the manifold cracking issue, or any other issues particular to ’31.

You might also download the ’31 Owner’s manual from the website under the Publications tab.

The 87-2 and 87-4 Arrows have a lot of information on the ’31s. I can e-mail you digital copies if you wish.

Dave

Alan,

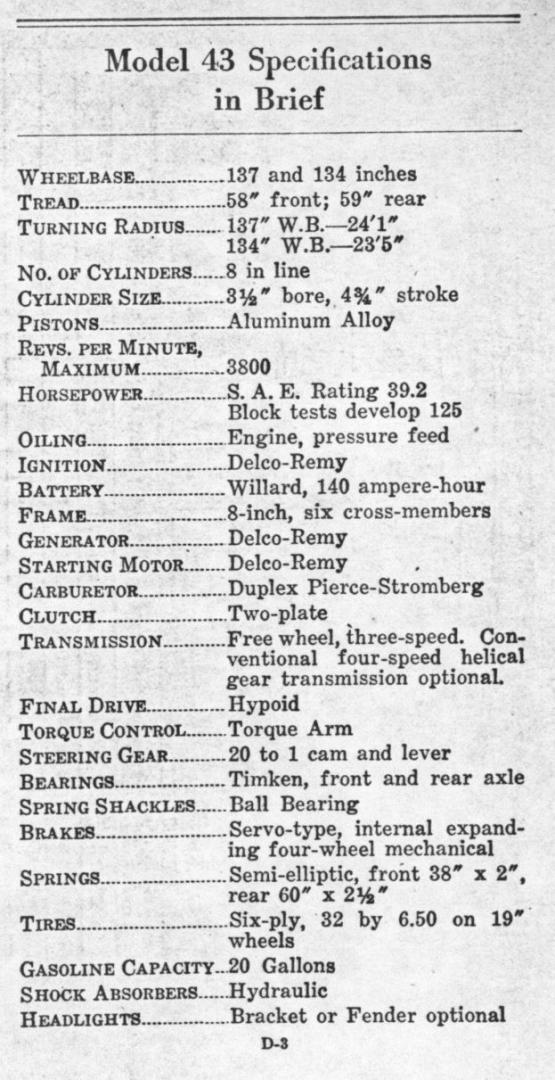

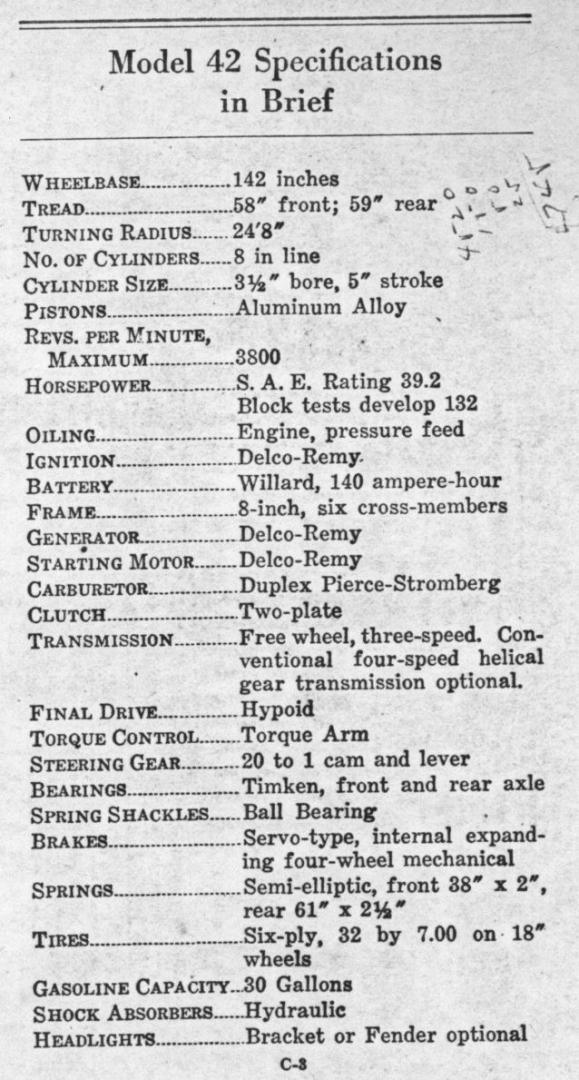

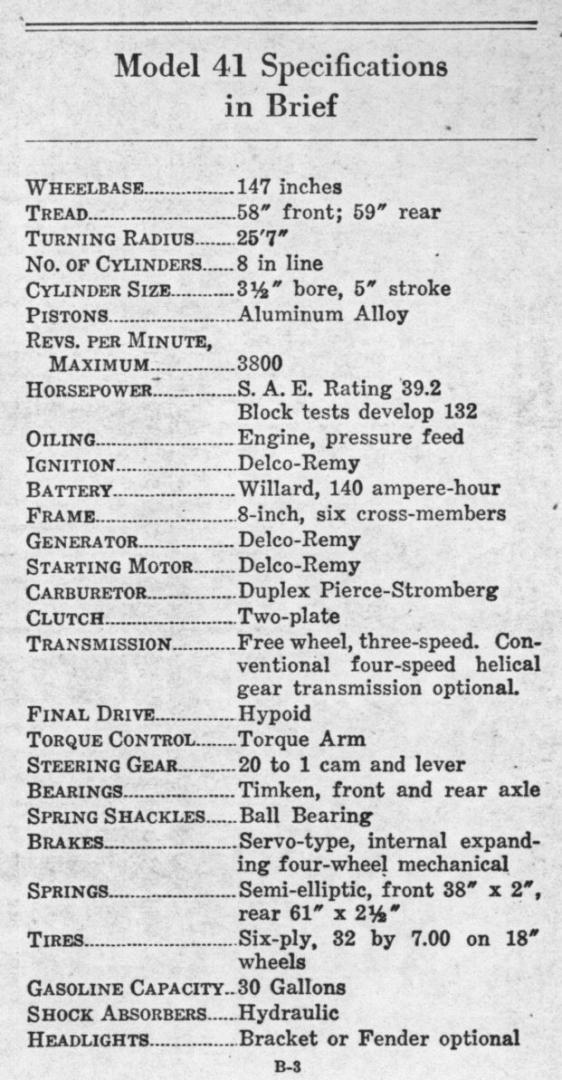

Here are a few pages from the ’31 Dealer Data Book. There also is a good article on ’31 models in Arrow 87-4.

It sounds like you covered things. What is your feeling about the arc, a high voltage arc, or a 12v arc? What is the arc length? By “Both show ground to the block”, you mean the coils show no voltage potential to the block ground? How about between the block and the chassis? I can’t see how the coil cases would have voltage potential to arc to the firewall if they are at ground. Perhaps I am misunderstanding something. I am hoping someone else will chime in with some ideas.

Have you replaced the secondary wires from the coils to the distributor? How about the rotor and cap? Electricity is going to take the path of least resistance, so if one of those has high resistance it might cause the spark to take a different path through the coil case. I have a hard time visualizing spark feeding back through the dist/coil primary wire, but I guess with some fault in the distributor it might. Dave

Carl,

I am a little confused (a common thing), are you actually seeing an arc from the coil case to the firewall? To me this says a breakdown inside the coils. Can you clarify? Dave

Try John Cislak. 413/543-9017.

Hi Carl,

If you do a search in the technical search tool, you will get a lot of articles about the archers (there was none for 1930). Enter “Archer” in the “Title” box.

There is a short article in PASB 1999-3, page 8 on 1930.

https://pierce-arrow.org/members/service-bulletin-library/

There also is information on the Bareheaded Archer in Arrow 1967-1. If you want it, I may be able to e-mail you a digital copy.

Dave

Brooks,

You might check with the LeMay collection in Tacoma. There are two LeMays, the original LeMay collection, and the newer LeMay, Americas Car Collection. I would try the original, on the Marimont campus first. Either may have some knowledge of an earlier Seattle collection. Harold LeMay had 1000s of cars.

Brooks,

That serial number is not listed in the PAS database nor in Bernie Weis’ files, so no help there. Hopefully somebody in the group knows something about it.

Dave

Mike,

From Service Bulletin 97-5:

1929 points and Rotor

(To: a member with a 1929 Pierce) ’29

The distributor on your 1929 is a Delco-Remy #668-E. Standard Brands

point sets #DR-2437-P and #DR-2236-P will work. Also, Echlin parts,,rotor

#RR-99 and contact assembly #CS 779-A, are designed to interchange.

The Delco-Remy part numbers for the points are: contact arm #813238,

and point #825452.

(OHK)

You might also check with John Cislak, Office Phone: 413/543-9017

Email: [email protected]

Dave

Yep, the bell of the horn is blocking the view of the number.

Yes, that is a casting number, not the engine number. Do you have any photos higher up on that side of the block that might show the engine number?

I see what you mean about the casting date code. It certainly looks like “1” or an “I”. An “I” would indicate 1928 which I guess is theoretically possible since I believe the first ’29 car came out in very late 1928. But I think May of ’28 is pretty unlikely. We really need the correct engine number.

Dave