- Home

- About Us

- Join/Renew

- Member Benefits

- Member Pages

- Log In

- Help

- Museum Store

Ken, a rope, not a rail, is correct for the S80 5-passenger sedan. If you can post a photo, I’ll tell you if it’s right. Your car was a 15,000-original-mile Harrah’s Collection car when I saw it in 1998 and before. Although some twit “restored” it, if they left the hardware in place and just re-covered the rope, you should be fine.

George

Thanks very much, Jim!

George

Richard, a period Dyke’s Manual is probably the only place today you’ll find info on the generator’s internal wiring.

The second…

Greg Long may well know the car and its owner.

Well I found two photos of the engine compartment detail but not of the car itself.

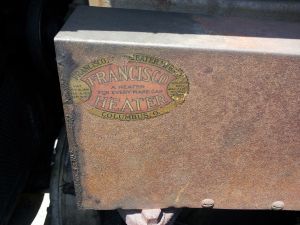

That was for an exhaust heater. The sheet metal portion on the manifold is almost always missing, as on my 1925 S80 coupe now owned by Hugh Harris. The only one I’ve seen was on a very original S80 at the 2015 Buffalo Meet–don’t think I have a photo.

A CLARIFICATION (I hope) and EXPANSION

Bob Koch and I have discussed zerk “Button-style” fittings and related lubrication issues and we believe that this topic needs some clarification and expansion for the benefit of those who are new to ownership of Pierce-Arrow and other pre-war vehicles.

I based my comment on lack of check balls for zerk OIL fittings on a discussion with an old machinist, now long deceased, who said that the lack of a check ball permitted one to see that the item was full without (slightly) overpressurizing. However, Bob and I know of no zerks produced in the last 60 years or so which do NOT have check balls. One machinery website says that check balls were used on machinery such as lathes (which use oil rather than grease as a lubricant) to prevent debris or other foreign material from entering the lubrication aperture.

Zerks may be used to administer oil of various viscosities OR grease, in both automotive and machinery applications. IT IS IMPORTANT FOR US TO KNOW THE INTENDED LUBRICANT, AND HOW MUCH PRESSURE MAY BE APPLIED.

When PAMCC went to zerks on both Series 80 and Series 33 in 1924, supplanting the old time-consuming 2-pin Alemite fittings, there were no check balls in those early zerks. Those cars were lubed not with semi-solid chassis grease as we know it today but with Pierce-Arrow “Special Compound” AKA 600-W “steam cylinder oil,” dispensed via a pistol-grip, push-type, small dispenser shown in tool lists as “compressor, grease.” Therefore, THE PRESENCE OF A ZERK FITTING IS NOT AN INDICATION THAT CHASSIS GREASE IS THE PROPER LUBRICANT. From all I’ve seen, 600-W and similar heavy oils were referred to as “grease” and sometimes as “liquid grease” in maintenance instructions with later disastrous results especially on Series 80 where owners have applied modern grease guns to dispense chassis grease through the zerk on the steering box and have blown out the seals—and chassis grease channels and does not lubricate properly.

(In the most general sense, semi-solid grease was called “cup grease” through the 1920s.)

Pierce-Arrow steering boxes through 1928 used the same 600-W as in their transmissions and (non-hypoid) differentials, NOT semi-solid chassis grease as one might expect from seeing a zerk fitting. The tool kit’s “compressor, grease” dispensed a small amount of 600-W with each push. This was also the dispenser for spring shackles and all other points equipped with zerks—and the reason why lubrication intervals were so frequent. On my steering boxes which have either Alemite 2-pin or zerk fittings on their steering boxes, I remove the fitting and use a syringe to top off the steering box with the appropriate lubricant—for fear of overpressurizing.

How much pressure may be applied: Some of you may be familiar with the zerk-fitting-equipped water pumps on 1937-48 Cadillac flathead V-8s. These pumps were designed to be serviced with water pump grease by small (6-8 inches long) grease guns with a T-handle on the end which screwed into the housing to force a very small amount of grease at LOW pressure into the fitting. Using a lever-arm grease gun (about 3,000 psi), or even worse an air-powered grease gun, will blow the seals and cause the pump to leak badly. Owners of these cars (I owned a 1939 Series 75 for 40 years) usually substitute a grease cup such as we have on our distributors, and install the zerk only for judging. So it is important to know the tools specified at the time for dispensing specific lubricants.

At last, back to the 1936-38 steering boxes: They take gear oil, not grease, even if they have a zerk fitting. And the check ball is of no consequence for our purposes.

Even more arcana: Zerks WITH a check ball are for GREASE; zerks WITHOUT a check ball are for oil…..

Because of the forward location of the steering box in 1936-38 cars, filling (at least on my 1601) is through an oiler tube with a spring-loaded oiler cap, which projects through the dust shield.. I’d use GL-1 SAE-140 gear oil unless you have a major leak, applied with a plunger-style oiler. Or you might try SAE=90 if that’s what you have.

Thanks, Peter, that’s what I get for going off the top of my head rather than looking at reference material. Here’s the info on Pierce-Arrow headlight lenses and diameters and markings 1925-1928:

• 1924-25 80 8 3/8″

• 1926 33 9 1/4″ STAR

• 1926-27 80 8 3/8″ STAR

• 1927-28 36 9 1/4″ STAR

• 1928 81 8 1/8″ STAR

ALL P-A CARS 1926-thru–1928 used B & L STAR lenses—that have a flat center panel –and the “star” logo at the bottom

NOTE that the 1928 Series 81 used a SMALLER diameter lens than 1925-27 S80s; the S81 had a 8-1/8 diameter vs 8-3/8 diameter for the S80s. So it is wise to note to outside diameter of any lens one contemplates purchasing, even if fluting and marking seems appropriate.

“STAR” marking on 8-3/8 lenses is for 1926-28 S80-S81, but the 1925 S80 used B&L without the “STAR” marking.

Excellent point, Randy! J found the same thing on my unrestored S80 5-p sedan. I attribute the looseness to fatigue of lock washers over the years, and have made a point of replacing most lock washers when I’ve had an opportunity to remove that fastener.

Now boys, play nice!

I have never seen a vanity clock in any Series 80 with a Pierce factory body, so the discussion of clock face colors is MOOT. Let’s MUTE it…

Congratulations, Ben and Linnea! We all wish you a long, happy, and healthy life together!

An ancillary thought about the single rear light (tail + license light) used from about 1915 until the triple rear light (tail + stop + backing) introduced in 1924: There is only room in the housing for a small diameter globe such as a #63, which is only 3 candlepower (cp). That’s not much light being emitted to the rear. Upon acquiring my 1918 48-B-5 early this year, I looked at my 6V bulb collection in hopes of finding a brighter bulb that would fit within the housing. I happened upon #209 and #210 slightly-elongated 6V bulbs used for interior dome lights, each of which produces 15 cp, a substantial improvement. The globe diameter does not exceed that of a #63 bulb. Some of you may know that already–I didn’t.

Likewise, for the rare night driving experience, I have two clip-on bicycle lamps with red LED bulbs, operating on a single AAA battery, which offer the option of steady light or flashing. They are about $10 each at Walmart.

Two other considerations:

1. Before streets were paved, in wet weather one would have to navigate mud to and from the left side of the car parked at the right curb.

2. I’ve read that 1920 was the year of the highest horse population in the United States. Whether the street was dry or muddy, one would have to navigate horse leavings to and from the left side of the car parked at the right curb.

Lest I become too scatological, I will refrain from mentioning the details of the pollution caused by NYC’s 500,000 horse population in 1900. That is rarely considered when discussing auto pollution….

Jack, Dave’s information immediately above is incredibly valuable and is worth many times your current year’s membership. It truly demonstrates the value of single-marque-club membership.

Dave, thanks VERY much for providing this info.

Afterthought for Jack: I know of no cases of *Pierce* aluminum crankcase cracking other than (1) a major front corner collision or (2) inadvertent dropping of an entire engine from an engine hoist. I’ve seen one example of each over 22 years.

Peter, I am indeed returned from (1) Rodney Flournoy’s 39th annual Modoc Tour out of Alturas, CA (64 cars, of which about 35-40% were Pierces, 140 people, 4 days, ~350 miles) in which I drove the 1918 48-B-5 touring, and (2) last weekend’s Ironstone Concours in Murphys, CA, where my 1934 production Silver Arrow was positioned tail-to-tail with Academy of Art University’s 1933 Silver Arrow concept/halo car. Now catching up on all the administrivia of life…

Jack, I’m unaware of external differences which might give a clue as to the innards of that 1927 crankcase. Very early S80s (up to about engine no. 805000) had a road draft tube emerging from the front cover/timing case cover. This was replaced by a flexible tube leading from a valve cover into the carburetor air horn, not Positive Crankcase Ventilation but an improvement in that direction. You’d have to drop the pan (a good idea if you buy the car) to determine if you have aluminum and/or drilled rods. It is indeed possible that over the past 90 years that some owner built up that engine from several S80 engines, but internal inspection is the only positive way of determining that.

Apparently there was, at some time, a complete engine change. The Company had the foresight to apply the engine number to the right front engine mount, part of the cast aluminum crankcase, rather than the cast iron cylinder block, which was much more likely to be replaced in service than the crankcase.

My own opinion is that there is virtually NO reduction in value caused by this engine change, unlike much more recent performance cars. But it could be a negotiating point.

There is a definite upside to a 1927 engine: They were equipped with drilled rods to permit pressure lubrication of the wrist pins. Early S80s had only splash lubrication to the wrist pins. Somewhere around engine no. 807000 in mid- to late-1925, tubes were added to carry oil under pressure from the big end web to the wrist pin web. Rolls-Royce also used this technique. The drilled rods are by far the best to have. And if this is among the last 500 S80 engines, it is likely to have the aluminum rods used on S81–and perhaps the heavier and better S81 crankshaft.

In my experience, S80s usually have a sequential divergence of 30 to 100 numbers between serial (chassis) numbers and engine numbers. Through 1920, those numbers were almost always the same. Also, in my experience, there is usually a smaller divergence in large-series (32/33/36) Pierces 1921-28, presumably because the build quantities were considerably fewer than S80s.