- Home

- About Us

- Join/Renew

- Member Benefits

- Member Pages

- Log In

- Help

- Museum Store

Pierce Arrow factory mufflers and pipes were ENGINEERED just for PA. The mufflers were what is called in the industry double wrapped. That is they had a muffler inside a muffler. ( Made them very quiet.) They basically were straight through with very little restriction. Also, all the pipes were mandrel bent. That is to say not crushed down to a smaller diameter when being bent in the machine. Thus the system was very quiet and had almost no back pressure. Unless you have a system custom made this way, you car will not run, perform, or sound correctly. An incorrect exhaust of modern manufacture that is run on 95 percent of the cars in the PAS from the Classic era causes the car’s performance to be reduced by about 15 percent by my best estimation. Long story short almost every car in the 29 – 38 time frame is too restricted and suffering a large performance deficit due to incorrect and over restricted exhaust systems.

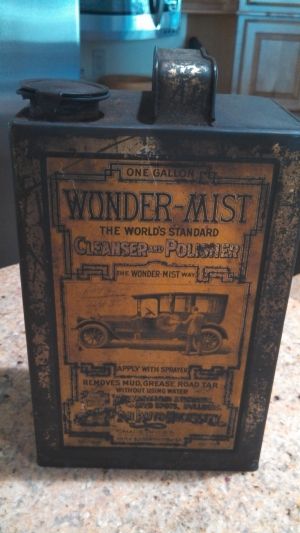

And a wonder mist can.

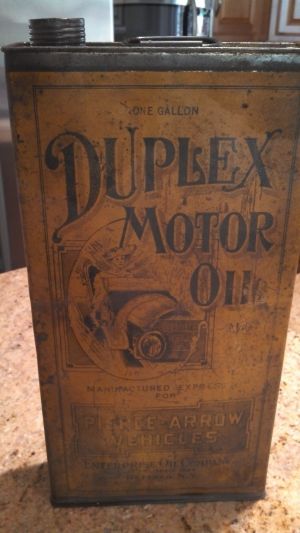

Here ia a one gallon oil can.

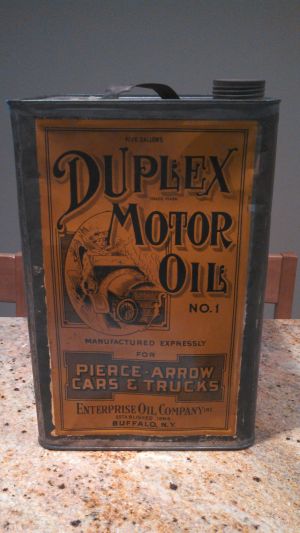

Here is a 5 gallon can.

They are a common if you look at Hershey. I see them on ebay often. I like the factory knob better. I see prices all over the place on them. They are collected just like lots of other garage items, I think the knobs bring more money from the collectors than the guys who put them on the car and use them. Ed

To be honest Peter, I have never considered myself “somewhat eccentric”, very eccentric YES, somewhat no.

American Arrow, Troy Mi. Ask for Don Sommers. Makes great products, in stainless. Perfect detail. Tell him I sent you. The may be others making them, I am not sure. Ed Minnie

Thoes are not correct for all of the applications he is listing them for. More often than not unless you buy from a rebuilder or PAS known listed vendor in the charts, you won’t get the right stuff. I have seen brushes filed and sanded down in an attempt to get them to fit, as well as wire leads half the size as they were new. It’s best to have your samples in hand and ask for additional photos to be sure what you are paying for is correct. Cavet emptor! Ed.

I was playing with a 10 Napier yesterday Jak!

Richard……it comes down to what was factory correct. Most Pierce collectors like their cars bone stock. Extra bling on a car of this caliber is considered tacky by most. That said, it’s you car, do as you see fit. You could buy them and put them on the shelf and install them after you have had the car judged. I am sure others will chime in. Keep the photos and questions coming!

I am sure John Cislak has the correct brushes in stocl for both Delco and Owens. The help offered here is one of the reasons this club is the best one of all in the hobby.

Not all series cars had them. I am not sure on 29 but the 30 and 31 cars had round on series B and 42, and series A and 41 were rectangle. I would not install them inless they are factory, or you will get points taken off when the car is judged. Ed.

Jak…..the car looks great. Drive it like you stole it!

Post it please.

You are too kind. Thank you very much. All my best. Ed

Who is Mr. Minnie?

Richard, I am a big fan of factory items like this. What I find most interesting is that after 40 years of Pierce Arrow collecting I have never heard of this vacuum, and I learned about it from one of our new members! That is what makes this car hobby so much fun. I think I know who your mentor is, he’s a good guy and a true Pierce Arrow collector.

Also, you need to fix the front seat back to body connection, as they were poorly designed and will cause metal to split and the lid to sag. ( The wood often is settled and out of position.) The vertical door post where it attaches to the sill also needs to be improved. Often there are issues that will not get addressed by people who are not familiar with this type of body style. Also, to prevent body rattles and squeaks, contact areas between the wood joints and cast and steel body braces need to be addressed. It’s common that a car with a total restoration will rattle and squeak because the body men don’t understand these cars. I can think of several 100 point Pierce Arrow’s that shake, rattle, and flex when going down the road.

The fasteners. As well as adding braces to the doors to prevent twisting and warping. Holding doors on with wood screws is a poor idea. We machine new bolts that look like screws and secure them using a steel backing plate with nuts welded on the back. Often touring cars have worn out driver door hinges. They often need to be recast as they are difficult to repair. It’s difficult for people with little experience in coach building to properly restore these cars. Most shops can paint well, getting correct panel fit and body alignment is difficult. It’s common to see cars with nice paint and poor body gaps, hood alignment issues, and other problems when modern shops do cars of this vintage. To get everything correct, one usually needs to assemble and disassemble the car several times to get everything right.

Richard, car looks very solid. You need to be sure the car is fitted before chrome goes from copper to finish, as the parts won’t fot otherwise. Also you should upgrade the door hinges to inprove long time fit and finish. If the people doing your car are skilled craftsmen but not familiar with 30’s coach built cars, you need to talk to some people to be sure you don’t run into problems later.