- Home

- About Us

- Join/Renew

- Member Benefits

- Member Pages

- Log In

- Help

- Museum Store

Jim, my ’29 has the three shoe, 15 inch brakes. These brake drums are steel and too thin to machine well. There is no source of new drums to fit a Pierce, so the shoes need to be made to fit the existing steel drums. Fitting new shoes to existing drums means wearing of the linings enough to fit in the existing drum grooves. Conforming the linings to the drum greatly increases the actual contact area between drum and shoes linings, making stops better. To conform molded linings, set the brake drag to match the wheel on both sides of the car. Do this for both the front and rear. Drive the car on a very quiet street while riding the brakes pretty hard (good to have a hand throttle). Many rounds of adjusting and driving are needed, but as the linings wear in, the car will stop much straighter and shorter. However, after conforming, that set of shoes will fit only the one drum. Woven linings have been preferred as they wear more quickly to match to the ridges of the drum. Molded linings take longer to wear in, but work well once conformed. Herb

Apparently, I am the designated contrarian on the website topic. Overall, I do like the drop-down menu system, much more than the “ribbon” style used by several current applications for office work. Many years ago, I was involved in several website designs and found the drop-downs easier to create, maintain and update with new colors, descriptors and other features than other navigation methods.

As for my suggestion; separating the member and non-member parts of the site does make sense, we should retain the separation, but make the guest / member sides more obvious. I recommend that one of the “pubic” pages or early in the pubic area, we provide detailed a navigation “map” explaining the Guest boundaries vs the Member areas. One possible way to designate this demarcation would be to use different color topic headers and drop-downs for the private vs public areas. Using color separation plus a detailed “map” of the entire site can be used as a marketing tool. Providing a fairly detained and descriptive list of member ares available to members only will let the prospective members see what they are missing by remaining a Guest. Allowing the guest to pull down the member topics (but with only blank data pages) will show the topics we provide as benefits to members . Certainly the public / private areas need to be separate, but the boundaries and “future features” once the guest joins can be presented more clearly.

OK, will get off my soap box now. Best Regards to all. Herb Tull

Lead-acid batteries will last longer than the 6 years if water is kept to the proper level and at full charge (hence use small trickle chargers when stored). The sure sign that a battery is on the way out is swelling of the case on sides or ends. Bulging of the case is a sure sign that at least one cell chemistry is/has sulfated over and is failing. One cause may be from inadequate charging (check voltage regulator or third brush settings). I have had 12 volt batteries in daily drivers that lasted 7+ years; while admittedly an extreme example, there is no reason to change batteries as long as voltage and specific gravity are within reasonable ranges.

Per Wikipedia: “As batteries cycle through numerous discharges and charges, some lead sulfate does not recombine into electrolyte and slowly converts into a stable crystalline form that no longer dissolves on recharging. Thus, not all the lead is returned to the battery plates, and the amount of usable active material necessary for electricity generation declines over time.

<span style=”text-decoration: underline;”>Sulfation occurs in lead–acid batteries when they are subjected to insufficient charging during normal operation.</span> It impedes recharging; sulfate deposits ultimately expand, cracking the plates and destroying the battery. Eventually, so much of the battery plate area is unable to supply current that the battery capacity is greatly reduced. In addition, the sulfate portion (of the lead sulfate) is not returned to the electrolyte as sulfuric acid. It is believed that large crystals physically block the electrolyte from entering the pores of the plates. Herb

According to Les Izmoor, simple is better in this application. The relay (flasher unit) is usually labeled “535” and available from $5 to $15 from several sources (NAPA part NF535 for $9.99). Being a simple coil and contact system, polarity should not matter.

I do recommend testing it on the workbench with a 6 volt lantern battery, a switch and a light bulb to verify it will work. the flasher mounts ahead of the switch. Label all the parts and make a wiring diagram for future reference. I keep mine in my Owner’s Manual.

Inside the car, install a 15 amp fuse in the power supply to the flasher to protect the rest of the turn signal wiring if the flasher fails closed. Herb

Jim,

Here is a suggested procedure to prepare and install your water pump suction line into your car.

First, clean the ends of the brass tube down to bare metal, being careful to remove all the old rubber contact material (probably copper sulfate from the vulcanized rubber). Be careful to do the final cleaning with a Scotch-Brite pad scrubbing around the tube, but not along it, shining it up. Remove all axial scratches as they can be the source of drips and leaks. The idea here is to make a length on each end clean and smooth enough for each new hose sections to slide completely onto the pipe, allowing this assembly to easily fit back into the car.

Second, Clean the crud from metal parts that will be on the other end of the hose as these will have to provide a sealing surface for the new hose. While this cleaning is not as important as the brass pipe, each must be clean enough to provide a good sealing surface.

Third, use a lubricant that will allow the hoses to slide easily on the brass surfaces and then back onto the mating pipes. I have seen glycerol lubricants used in both industrial and commercial environments with good success. However, most of these are made with an oil base leaving a residue. Adding any amount of grease into a cooling system is a bad idea. The best material for this application is a glycerol lubricant made from a water base to dissolve completely into radiator water without any negative consequences. The one I recommend is the famous KY jelly. Available at local drug stores in a convenient size tube for this task.

Fourth, apply the lubricant liberally to inside surface along the full length of each hose. Then apply liberally to the outside of the brass pipe at both ends, each a distance longer than the hose used. Each hose should now slip their full length onto the brass tube without much problem. Be sure to slide the both hose clamps onto each section of hose even before carrying the assembly to the car! I learned this lesson several times the hard way about putting both clamps on the hose before making the connections.

Fifth, once the new pipe and hose assembly is in the right location in the car, loosen both hose clamps on one hose and slide it off the tube until properly seated onto the mating part. Snug both clamps on this hose and then repeat the sliding procedure on the other hose to its mating part. You still can adjust the center pipe to where you want it, sliding along both hoses. Tighten all four hose clamps once adjusted and the cooling system should be ready to hold water, without introducing grease into your cooling system.

Regards, Herb

Reminds me of the 1976 Johnny Cash song “One Piece at a Time”. Watch the YouTube version. I do like the way whoever put this unusual vehicle together used the same part for both the tail light and the light on the back of the front fender. Clearly, lots of imagination went into building it. Were they sober at the time?

The Pierce headlight location patent (US1758305A) was set to expire in 1947 at the end of its protected period. It may have expired earlier when the company was liquidated in 1938. If no one pays the annual fee, the patent becomes “abandoned” which cancels the protection, moving it to the Public Domain. Since this vehicle looks to be newer than 1947, I don’t see a problem with placing the headlights where they did. Kinda cool, actually.

On the other hand, back into good condition, it would be a real head turner at local shows or the annual Christmas Parade. Go for it, Bill! What a cool Hot Rod you could have. Herb.

Randy

You can have your machinist buddy come measure you hub directly with a micrometer and a thread gauge. Measure the hub first with a ruler or tape, so he will know what size micrometer to bring.

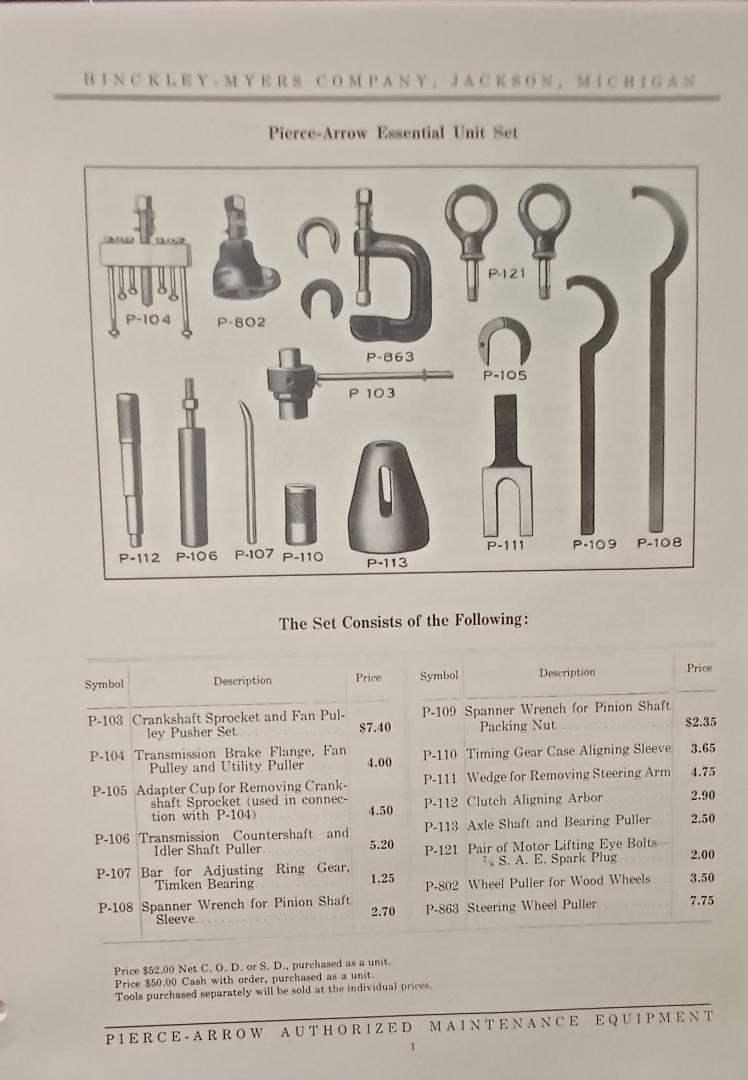

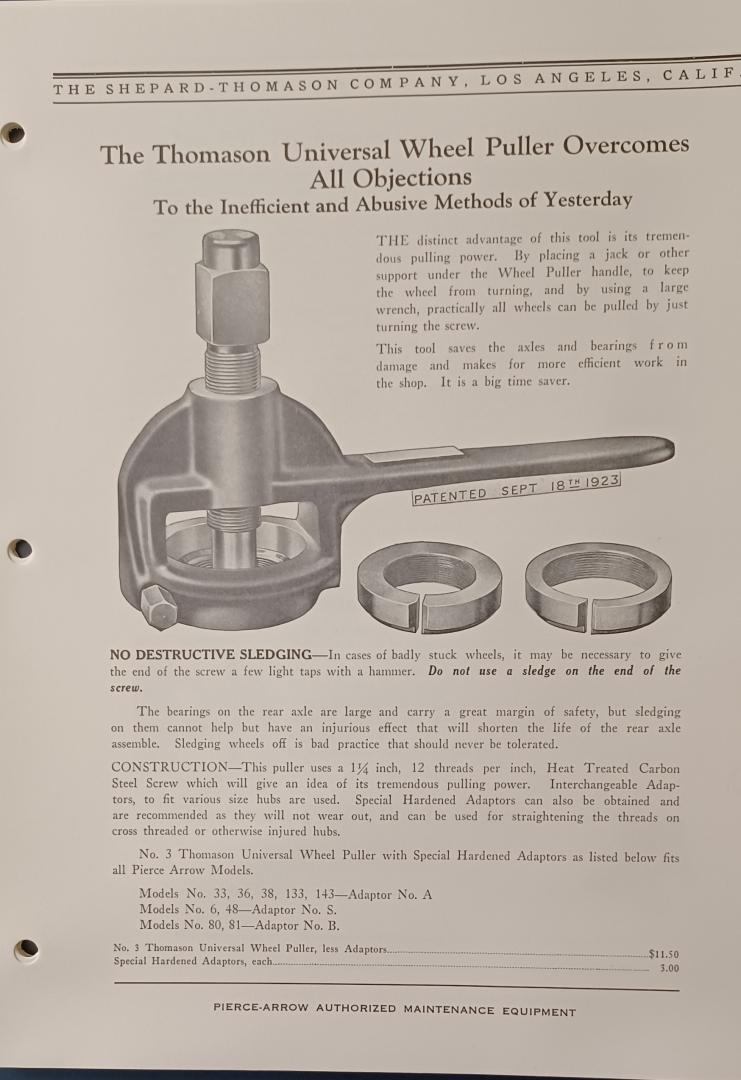

Attached are two pictures of hub pullers from my copy of the “Pierce Authorized Maintenance Equipment” book. There are no page numbers, but you can see the different concepts. The Thomason type will be the most versatile, as you can m ak

ak e it work with either of your cars by having two different thread inserts made. Good luck with the essential task of reworking the brakes. Herb Tull

e it work with either of your cars by having two different thread inserts made. Good luck with the essential task of reworking the brakes. Herb Tull

Both elements of ending slumber can be fun. Waking and starting the old cars from their winter slumber for another enjoyable driving season or waking the house from their morning slumber. Having done several similar things in my past, I won’t ask which was more enjoyable. Beginning another season with the old cars is certainly more gratifying for a longer period of time, but waking the whole household can bring much more immediate excitement. To repeat the old Esso slogan, “Happy Motoring” to you and yours this summer. Herb

Thanks for all the complements on my Pierce, I do appreciate it and want to show it soon. I can tell that very few miles were driven during the last several years, so I will attend only local shows this summer. Building some driving hours will loosen things up and help smooth them out. Next year’s goal is driving to the Glen Falls meet but there is more stuff to sort out before going that far.

The brake shoes are molded and do seem to have about the right arch for the drums, or at least close enough. As expected, the steel drums have wear ridges and grooves around the braking surface. However, the shoes looked brand new and were very smooth across their faces. Having no mating grooves to fully engage all the drum surface really reduces actual contact area. Breaking in new shoes to match the drum’s actual surface profile will make the the brakes much more effective with more actual contact area between shoe and drum. After three cycles of run the brakes hard and then adjust the shoes on our last adventure, the old battery decided we were done for the day.

More hard down hill runs and then adjustments will wear the shoes for more stopping power, which is the immediate goal. We also seem to have significant lost motion in the pedal travel before the shoes contact the drums, likely from wear in the rod clevis mechanisms. Reworking all the clevis joints should cure much of the lost motion – but is a task for next winter when I can organize my tools and equipment around the car in my new garage. Herb

Bill,

The flat helix around the upper end of the spring in your picture is a damper and yes, you need to keep it. The reason for the damper is to prevent the spring going into “resonance” and breaking when the engine speed is at that exactly wrong speed. I expect that earlier years had more broken valve springs than expected, so this damper was likely the Pierce factory fix for your car. Dampers are still used in some racing engines to prevent resonance vibration and float at high speeds. Search for “valve spring damper” and look at the images; same concept but the flat coil is now inside of the helical spring. After cleanup, put your damper back on the spring and install this combination in the same orientation as found during removal. This damper works by friction and should be slightly snug around the valve, enough to touch it, but not restrict spring movement. The idea is to change the natural frequency of the spring, but not change the spring force in either the valve open or closed position. Hope this helps. Herb

The good news is that you have saved one more Pierce from the scrap heap. It will be an interesting vehicle to see when you finish with it. Have fun with this project. See you at the next East Coast event. Herb

Bill, These pictures of your engine work look really good and show the progress you have made. So, congratulations! The tie wires are inside the oil pan and totally out of sight where nobody is ever going to inspect, so measuring twists with your eyeball is quite sufficient.

For us nut jobs who are REALLY hung up on having EXACTLY the recommended twist in tie wires, we first need our heads examined. However, if we still INSIST on verifying the pitch, there is an easy method. The UNC scale shows both 1-1/8 and 1-1/4 inch bolts using 7 threads per inch. Most thread gauges do have a blade for 7 threads (or twists) per inch, as well as many others.

Please keep us posted as your adventure progresses. Herb

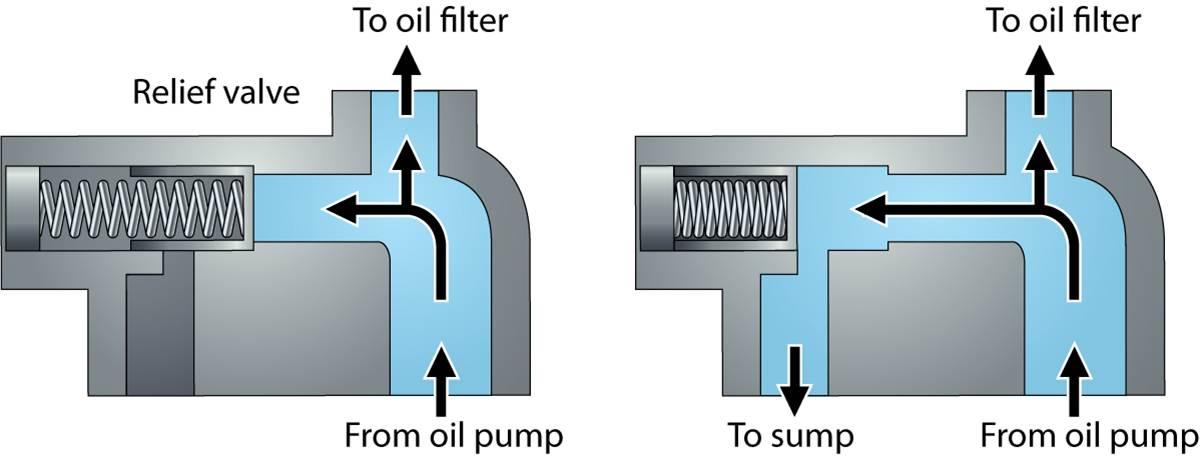

Randy, What would be the purpose of a grease fitting into the engine oil system? Is this a point listed on the lubrication chart? At best, the grease would dissolve into the oil and increase the viscosity slightly. If the grease remains in globs, it could clog oil passages inside the lifters or other small pathways in the pressure side of oil supply system. I expect it is more likely the threads in the relief valve body are for the tube fitting to the supply line for the “dirty” side of the oil filter. If the filter is mounted above the pump, then a check valve is needed to prevent dirty oil from flowing back into the engine when the car is shut down. What other device on the engine could provide this function? Modern replaceable oil filters do not have black flow if mounted below the normal oil level. Filters mounted above normal oil level do need a “flow back prevention” feature. Has anyone in the Society cut open one of these old style filters to see if there is an internal check valve? Regards, Herb

Bill,

Step #1 is to trace out your oil flow diagram to confirm what is going on. The rumor is that all Pierces with oil filters used a “bypass flow” type connection. If the bypass flow device is on the high pressure side of the relief valve, then this is likely to be the port that is the inlet to the filter. The reason for a check valve on such a device is to allow oil to flow up and through the filter when the engine is running. When the engine is off, this check should close to prevent the accumulated dirt in the filter from draining back into the engine. Pierce combined these two functions into one device, there should be a small ball as part of this check valve. Happy hunting for it.

Hope this drawing (from Pelican website) helps: Herb

John, With only one 6 volt coil in a 6 volt vehicle, no resister should be needed. Check the resistance of the primary coil, should be between 1.2 and 1.5 0hms. If the coil resistance is below about 1.2, it’s time to look for another coil. The “battery ignition” system should draw about 4 amps, so a 5 amp use should work in your fuse box, but a 10 amp fuse will be more reliable. Check your wire size and condition (new #18 is good for 10 amps, #16 can handle 13 amps. If the wire goes inside a conduit, use #16 – it will take more heat, then use a 10 amp fuse.). I strongly recommend using stranded wire, as solid wire will break from vibration – and that problem is difficult to detect and fix on the side of the road. Herb

John & Allen; I may have a fix for your resistor problem. I assume your ignitions are of the “two battery” type with no magneto. The ignition switch should look similar to the 0ne shown in the 1919 Owner’s Manual, where there is one ignition wire going into the switch and two coming out, one each headed for one of the coils. From what I have seen, most 6 volt coils have a resistance of about 1.2 to 1.5 ohms, using a current of 1.2 to 1.5 amps. Please check the resistance of your existing coils to verify that the primary is about 1.2 to 1.5 ohms. When the coils are in parallel, the effective resistance in that part of the circuit drops to about 0.7 ohms. If the target current of 4 amps is to be met, another source of resistance is needed to reach the total expected value of 1.5 ohms. For a target of 6 volts and 4 amps to each coil, an additional 0.8 ohms needs to be added to the single wire part of the circuit, BEFORE the ignitions switch. This location puts the resistor in series with the pair of parallel coils. This new resister will generate 25 watts and get HOT. Do NOT mount it on a wood panel. Use a 10 amp fuse in the block, then hide this resister somewhere under the hood – out of sight, but with plenty of air flow. This is what Chrysler did with most of their cars in the 1960’s.

There is a resister with 0.8 ohms at Summit Racing. It is from an MSD after-market ignition system. Part Number is: “MSD Ignition 8214” for $13.36 and shows to be in stock. It will keep voltage at each coil close to the nominal 6 volts. This value may not be exact, but will be better than nothing. Regards and stay warm, Herb

John, I looked in three sources and found 3 different answers for the 38 HP car battery ignition(?) circuit resister.

1) The PAS owner’s manual for C4 is a marked up version of the 1916 model C3. It shows the C3 with a volt meter in the ignition circuit, which will not read properly with a resister. No resister is shown in that diagram, but a pencil note “ammeter?” is in the text.

2) The PAS Wiring and Tune-up guide, from the Company Store (page 6, for Series 4 &5, 38 & 49 hp), does show a resister and an ammeter. It is a partial diagram, showing no ignition wiring, so no real clue where it fits in the full wiring system.

3) The PAS owner’s manual for a 38 hp car in 1919 has a wiring diagram with NO connections to space #1, so no resister. The Wiring and Tune-up Guide diagram agrees.

*If your car has only one battery ignition circuit using a 6 volt coil, and the other a magneto, then no resister is used. *If your car has a volt meter instead of an ammeter, then no resister is used. *If your car has two coils in parallel, then a resister may be useful, depending on effective resistance of the coils – but they should still operate OK for quite a while without a resister. If the coil has a nameplate showing the preferred voltage, then we can do the math for the level of resistance (ohms) and wattage (for heat dissipation) needed.

My only real experience with a ballast resister was a 1967 Plymouth during college years. That resister was a large ceramic thing that would be difficult to hide on your car. Web references discuss ballast resisters only when using a 6 volt coil in a 12 volt car. My ’29 does not have a ballast resister for either coil. I hope this helps. Best Regards, Herb

Jim,

Fuel delivery systems must satisfy two conditions: Zero demand before start-up and maximum demand on a long mountain grade. Gravity systems; vacuum tank or Ford Model A, can deliver fuel at nearly fixed pressure during all conditions. Mechanical pumps deliver fuel proportional to engine speed; very low during cranking and increasing with engine speed.

Electric pumps must meet both flow conditions with fixed output, often by using a regulator for pressure control. Too much pressure will flood if the float valve does not shut tight, but too little will starve the engine under heavy load.

The electric pump my ’29 PA uses has a separate switch under the dash – not direct to the ignition. Separate switches allow the engine to start with the fuel already in the float chamber. Then this switch is used to provide flow when running, or run it just a few seconds on a hot day to prevent vapor lock before cranking.

Setup of the carburetor will also have a large influence on the pressure needed or tolerated. If you want to dig deeper, send me an email. Herb

Joe,

Yes, I do want one of the new sectors you are having made. When I purchased my Pierce, the hand brake did not hold at all, so I had to remove the sector and file to the teeth enough to make them at least functional; it works for now, but I do not trust it for long term use. The pawl appears to be in good shape, so I am reluctant to cut the rivet to replace it. Having a new sector with consistent teeth, rather than my amateur “dentistry” will be a very welcome improvement for a car that will be driven. Herb

The 1929 Pierce Arrow Parts Catalog proves its worth again. Page 18 shows the transmission and the view of the top shows the handbrake mount. The sector is noted as Part Number 123037, and is confirmed in the numerical parts list section. Joe’s reproductions are expected to fit models using this same part number. What hand brake sector are other models in this era using?