- Home

- About Us

- Join/Renew

- Member Benefits

- Member Pages

- Log In

- Help

- Museum Store

I had the problem of 18″tubes supposedly fitting 7:00 17 a few years ago. The tube was too large and ended up with some folds that resulted in two simultaneous flats on two brand new tires. Did lots of searching and found a 16.5 radial tube and they have worked fine for several years. I had an original 1935 Goodyear tube still on my Pierce, didn’t hold air anymore but had been a vastly better tube. It had a run flat safety double tube-in-a-tube and was very heavily reinforced where it contacted the wheel. Probably never see those made again. Jim

Jim

I have been fussing over the colors to paint my ’35, and can say that I at least cannot tell from color chips or even large sheets how a car will look unless you actually paint it on the car. It is amazing how different the impression of a color is on the car than looking at a sample. I just painted a second variation of one color that was nearly indistinguishable from sheet metal strips painted the two colors as mixed. On the car the difference is striking. I now have had 10 different color samples mixed for the body color and two for the belt moldings. I have 5 different areas of the body painted with different combinations to compare. I think I finally have a combination I am happy with, but going by color chips alone would have created a very unfortunate combination.

To be truly authentic make sure there are plenty of runs in the paint, don’t fill in the mill scale pits or grind down the weld splatter. At first I thought the pits in my ’35 were rust but when I sanded down there was original red lead primer in the pits. I think the bare parts were sprayed with red lead primer but the final black was done after at least partial assembly. There are places such as under the spring hangers that the black was shadowed out with only red showing, so apparently the final paint coat on the frame was done after the springs were installed. The original chassis paint looks like it was a quick job done with plenty of runs when at least partially assembled. For those getting their cars judged, perhaps there should be a point deduction for chassis finished too well.

Having only a single car to study, I have wondered whether the earlier cars were finished better underneath but standards suffered as the company sank towards bankruptcy in the mid ’30’s.

Re the mechanical complexity of Packard valve train vs Pierce. The question was asked above!

When I first started looking for a car to restore in 1980 I was interested in either Packard or Pierce, love them both. I have unjustifiable prejudices against Cadillac but not 2 of the 3 “P’s’. I found the Pierce I am currently working on before the ’36 Packard but the owner decided not to sell so I waited ten years and after my Packard restoration before getting it. It will be a few years before the Pierce is done so I can do a driving comparison. First I will say that my Packard has never failed to start in 30 years using 6V and original points and coil (except when I let the non-optima battery go dead from sitting too long – knock on wood). In the Packard Club of course I hear lots of snide comments about so and so’s Pierce that never starts. Probably has nothing to do with it being a Pierce.

The reason for the more complicated roller valve followers on Packard is of course to reduce wear on the camshaft. A nice attribute now that ZDDP has been eliminated from common engine oils since flat tappet engines can have problems without ZDDP. Of course the newest post-modern cars (modern cars are 1960’s) have reverted to more complicated roller followers for this reason. Engines with high loading, high piston speeds, and long life requirements usually have roller followers including WWII aircraft and Diesel engines. A problem with the simplest form of roller follower attached directly to the valve tappet is the high side loading put on the tappet guide. The swinging roller arm of the Packard 8 eliminates that side load and uneven wear of the tappet guide that occurs with simple flat tappets. That design dated to 1923 and is very long lived and reliable. The 1933 hydraulic tappet design of Pierce was very innovative and of course won out over the more complicated valve silencer arrangement of the Packard V-12.

I am eager to get my Pierce with it’s hydraulic lifters and 3 stage exhaust system going to compare with my Packard 8. Those hydraulic lifters with flat tappets are of concern, however. My engine was partially rebuilt in the 1960’s and based on what I have seen so far I don’t have a lot of confidence that the lifters were kept in their original positions. Typically of course with used cams and lifters, one is supposed to keep lifters on the same cam position as they originally wore in with to keep from having additional wear, possibly through the case-hardening. The saving grace is that it seems unlikely it will be driven more than 10,000 miles before the end of time. At any rate, It would be a couple less issues if the Pierce had roller followers a la Packard.

So there you have it, a blatant unapologetic heretic! Sometimes feel like a Quaker in a Southern Baptist convention!

Jim

David, thanks! I’ll check out the Onan condensers, maybe the best solution.

Jim

Thanks Ed, that helps. Might be a few years yet before I would be able to contribute any experience, I am repairing the rear trunk surround wood, then it is trunk lid framing, some rear body repairs before re-mounting the body and dealing with doors, all before the engine/trans (counted in years).

I tried to install a Pertronix drop-in kit on my Alfa a few years ago and it simply didn’t fit. Tried to install both a Pertronix and a Mallory complete distributor into my 440 Chrysler and they didn’t fit (trying to avoid previous bad distributor rebuilds and amazingly poor new-built points). Finally put a Pertronix drop-in kit in a rebuilt distributor. It fit and so far (

It is a challenge and a bit of fun trying to get the right colors. I decided that the only way to get a real feel was to paint part of the car. Years ago (sorry, Packard again) I started with a plastic model and mixed model paints to experiment and get what looked right. I then had some original Ditzler mixed of a factory color formula that was quite close to what I came up with on the model. Looked good on sheet metal bits dipped in the paint, but then when I sprayed part of the car it wasn’t quite right -too “fleshy” i.e. “warm”. Then had a few other factory colors mixed (from Ditzler formulas). One was a metallic green-teal that was stunning in the can and on a metal sheet, but when sprayed on the part of the car it was obvious it would have looked garish and stuck out like a sore thumb. Ditched that and went back to the beiges all painted on the back end of my parts car. It took a few more iterations, and the result was a light but still conservative color in the vein of the beautiful ’35 coupe above. If anyone were to whine that my color is too light and not “correct” (haven’t done it to my face), I have a color magazine ad showing a car pretty darn close to that color.

Most of these cars were originally dark colors – no argument. I think the impression of color has a lot to do with how close you are standing to the car. Close up a well done dark color looks incredibly deep and beautiful, but from a distance that is less of an impression than the overall lines of the car. I feel that dark monotones tend to hide the beautiful flowing lines and lighter colors are better from a distance, if not up close. Since I am more concerned with how the car looks on the road for people who are amazed at seeing a relic out in the traffic rather than on a show field of critics, I gravitate towards lighter colors.

One of the things I like about the ’35 P-A was that there were a few somewhat unusual factory options for the belt moldings to be a lighter color than the base, and that really can accentuate the lines of the car such as the ’35 coupe above. Trick is getting the right amount of contrast. I had the original P-A Patricia Blue/Alpha Blue combination mixed with Ditzler years ago, as well as the two-tone green combination (Moss green light and dark). Unfortunately, when you get away from the basic blacks, almost black blues, and almost black greens most ’30’s factory colors tend to be “muddy”. Not my term but the comment of the guy mixing the paints for me. We have a choice of being historically accurate or highlighting the design of these cars as things of beauty and a joy forever. I have always admired the lines of these cars, particularly ’33-35, and feel it was an unfortunate slap to the loftsman who carved out those flowing surfaces that they were penalized with a trend of those years for “muddy” colors. I have more respect for the designers and engineers than the production manager at Pierce who chose the simple monotone blue to slap on the car to minimize cost for cars they were “dumping” in Wisconsin (a surprising number of ’35’s were in Wisconsin).

I am still futzing with my ’35 P-A colors. Pulled the body back into the garage after being covered up for a couple months outside while dealing with the rear axle and springs. It has three different combinations of body/belt molding colors and my favorite from a few months ago doesn’t look right anymore, so back to the paint store.

Jim

I have started to consider going to Petronix on my ’35 even though I have a stash of left and right hand points for the original. I agree that the originals work just fine, but the fear is bad condensers. Finally put a Petronix in my ’66 Chrysler after the new condenser failed after a few years, then the cheap new points lasted less than a year and a few hundred miles before wearing down to zero gap (yes, the cam had lube). I have had several problems with new manufacture condensers over the years, and unfortunately condensers are one of the things that age can effect so getting an 80 year old NOS condenser probably wouldn’t be trustworthy either. I think the choice boils down to whether you have a set of good points of old manufacture and a reliable (how do you tell?) condenser. My Packard has done well for 30 years on its original 1936 coil and a 1980’s installed condenser except when I burned the points mis-remembering correct spark plug gap (duh!). My fear is the coil and I carry a back-up coil in the car that I have yet to need.

Bill, your carriage bolt scheme would have worked on my bearing cups, good idea, will keep it in mind for the challenges to come!

I feel your pain (sorry for the cliché!) finding the pits in your worm pinion. I was holding my breath when I drained my ’35 and was lucky that oil came out and no water. After pulling the cover the teeth all looked beautiful, so I really lucked out there.

Replacing the rear axle bearings wasn’t without challenge however. Kept making new shims to add as I seemingly couldn’t get any axial clearance when I bolted up the left side. Finally realized the axle housing land must not be quite square and it was binding the bearing whenever the bearing housing was tightened up. My ’35 had about 60,000 miles on it and it was the bearing cup that was being pre-loaded in that direction that had failed. The preload also coincided with the side reacting the weight of the car, so that is probably what caused the premature failure. Maybe was the final straw that caused it to be parked in 1948.

Hope you have good luck with Bob Jacobsen’s worm assembly!

Jim

Bill, interesting. Noted the pullers for 31-32 Pierce for the “specialized shop”!

Just had more fun with rear wheel bearings. After inspecting the rear differential which was a thing of beauty and a joy forever, thought I might get by with good rear axle bearings. No such luck, so had to pull them. After looking through PASB’s apparently some of you guys can punch out roller bearing cups banging away at a 45 degree angle (or I am missing something). At any rate I’m not that good and prone to pounding on my hand instead of the punch, so I ended up grinding the legs down of a small 3-leg puller and used it inside out and backwards to grab the bearing cup at the three machined indents in the hub. Seems like there should be an adaptable puller out there for this, but I couldn’t find one.

That’s what I used. 30 years ago when I did my Packard the only canvas I could find in town that wasn’t a big tarp was a bit heavier and pink. Don’t remember why I had such a problem finding it but I still have some left. Could have used it on the Pierce, but it always bugged me that it just wasn’t right using pink canvas, so I found some tan this time.

Just finished replacing my original covers. I did it with the springs remounted to their shackles on the car. Actually, I assembled and greased the spring leaves on the car. The rears are pretty heavy and I have reached a point where I have to be careful of my joints and how much heavy lifting and twisting I do. For this reason I mounted the main leaves to the fwd hanger first and did the adjustment to the Fafnir ball bearings. With only one leaf it was much easier to judge when the hanger bearing reached a preload. I then greased the bottom of the main leaf and added the next leaf using 3 clamps and the spring bolt to align. When I had about 5 of the leaves assembled and clamped the arch of the spring was about right to assemble the rear shackles and torque. Then finished adding the rest of the leaves and added the nut to the bolt for the final compression of the leaves after removing the clamps. Then added more grease to the bottom and did the canvas and covers. 1 can of grease per spring. Not the way it was done at the factory, but much easier on my joints.

I also did the front spring covers after being mounted to the car. Of course I probably would have done them off the car if I didn’t have the great luxury of a lift to do it at a comfortable height.

As Michael noted above the best I could tell of the semi-rotted canvas when I took it off with big mess of long dried up grease was that it was simply cut and wrapped lengthwise with a bit of overlap on the bottom. “barber pole” might be a better way but I think the overlaps would risk the covers not fitting over the extra thickness. The grease kept the canvas in place nicely while putting on the covers. I don’t think it is necessary to grease the outside of the canvas, and not doing it greatly reduces the mess. I put the covers on from the middle of the spring and worked outward, I think it would be really difficult starting from the ends as each segment wraps around the outside of the next segment towards the middle.

By the way, if it helps at this point my originals measured .020-.022 thick. I can’t say why I think this, but I think they were terneplate, which is fairly similar to galvanize.

A mistake I made on my Packard years ago was waiting until they were installed to paint them. They move around with the spring flexure so I ended up with little bands of unpainted metal showing through. This time I painted all the segments separately before installing, then I will paint again after installation.

Have fun!

Jim

Bill, am in the process of re-assembling the rears on my ’35. My original covers were in fair condition and as discussed last year when I asked they are very soft metal that easily unbent to take them off and had no problem re-bending to put them back on without cracking. I believe the wrap material underneath is canvas, and that is what I used to replace. The canvas was there to help hold the grease in, and when I took mine apart and cleaned them there was no doubt the leaves were slathered in grease then wrapped: I had to clean it all off the leaves. There was some discussion a year ago about this, but I am redoing the original way, thus I am now in the very messy process of re-assembling the leaves and coating with grease between every leaf. Did the same to my Packard 30 years ago and it is still squeak-free – knock on wood.

By the way, there were 10 total covers/spring on the rear of the ’35, and “fair’ condition means almost every one had been stabbed by a screwdriver. I assume someone was trying to force grease in to fix squeaking, which likely was actually happening at the ball bearing pin of a rear shackle that had “landed” on the backup ring of the shackle bearing when the pin had been pounded in by the ball.

Good luck making them, you are definitely a hands-on doer! Loved your remanufactured horn ring!

Jim

The flakes used in the 30’s metallics were extremely fine and provided a much more subtle opalescent quality than modern paints with big flakes. The metallic colors were usually quite conservative and when done well (hate to use the work proper)are hard to tell at first they are actually metallic. Hardly “circus wagons”. You can probably tell I am thinking of using metallic on my ’35, the starting point being the 2 tone factory “Alpha Blue” and “Patricia Blue”. I have mixed around 6 sample colors now, starting with “standard” paint supplier color mixes and substituting only the fine grade flakes for the courser. Substituting the fine flakes does significantly shift the colors so it takes several tries and painting swaths on the car to fuss over what looks good (to me and my wife). Not quite there yet. So far the non-metallics just don’t quite look right. Many of the 2 tones in the ’30’s were very subtle, barely able to tell in some light, but the Alpha/Patricia combination did have more contrast than some. The Packard in the foreground departure point was a non-metallic Packard color “Dawn Gray”, but is a 1980 non-metallic Lincoln color.

Being in the camp of doing colors that look best on the car versus absolutely original I cling to the usual argument that virtually the whole spectrum of colors could be custom ordered from the factory- including metallic. 1/2 of factory color options for Packard in 1936 were metalics (but metallics back then generally used only the finest size flakes, not bigger ones common now). A friend knowledgeable about paint history pointed out to me that most of the candy colors like vibrant purples popular in the ’60’s weren’t achievable in the ’30’s. Don’t know about Pierce, but years ago in the Packard Club there was a dispute that although technically you could order any color, it was rarely done and shouldn’t be condoned by the club. One of the guys who worked in Packard’s design group in the ’50’s responded by recounting the big wall of index files full of custom color and interior orders dating to the the ’20’s. To try and justify my stance I also use the technical argument that you can never know exactly what the color was when it was delivered. The color chips fade, they weren’t necessarily spot on in the first place and they weren’t always consistent. Bits of paint protected from the elements are pretty close – but still age to some degree. Years ago there was a paint shop that still carried original Ditzler pigments and could mix ’30’s colors to the original formulas in lacquer. I had several mixed when choosing colors, but even there, how much have the pigments shifted with age sitting in the can for a few decades? In the end one get pretty darn close but there is no such thing as an “exact”” match. My personal choice is to drive a truck through that argument and modify the colors to get something that looks good to me and still is in the “”spirit”” of the original colors – but I also never have my cars judged.”

My 845 is stepped like this, it has never been bored. I wondered if it was supposed to let the ring compressor slip into the bore on assembly to reduce the tendency of the rings – particularly the cast iron oil rings – from catching and breaking when being tapped in. Haven’t actually gotten to the point of trying it. Another theory: the step corresponds to the top of the ring travel and avoids having a ridge from wear that catches on the rings when trying to pull the pistons.

Jim

If as Rick notes you have threads on the end of the drum, that could make for another variation on the pipe flange idea that would not require pulling on the studs. An unthreaded pipe flange could be machined and threaded to screw directly onto the drum hub center thread, then another matching flange cap placed on the axle+axle nut and four bolts put through the four holes in the flanges. Actually less machining, except for the inside thread part that is beyond my (low) skill level. Keeping the axle nut on means everything is trapped and nothing will come flying off. Didn’t know anyone was in the business of building new pullers, sounds like a good place to start.

Jim

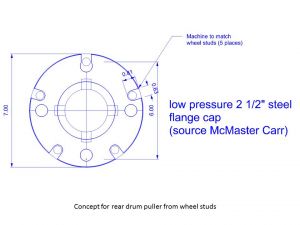

Craig, one can imagine the rear drums were modified to incorporate the 4 ears because the repair shops were having the same problem pulling drums way back when. Like others have reported, when my drums came off the tapers looked as clean as the day they were assembled, corrosion wasn’t the issue keeping them stuck on. At any rate, it seems like if you don’t have the option of the 4 ears, the next best alternative is pull the drums from the wheel studs, and the best hope of doing that without pranging the drum is pull on all five studs evenly and progressively. A thought for doing it with the same idea of the pipe flange caps is machine a larger flange cap with five slots to match the 5 wheel studs, see attached drawing. The flange cap comes with 4 pre-drilled holes but of course 4 holes don’t line up with 5 wheel studs. Then get 5 coupling nuts and bolts. the coupling nuts would screw onto the wheel studs. I believe 1/2-20 fine thread is what my ’35’s are, and I confirmed 1/2-20 coupling nuts are available from McMaster Carr. I think such a puller would have very good stability and not come flying off as long as the axle nut is on the axle flush with the end of the shaft (leaves ~1/4″ movement for the drum when it pops off the taper).

One of the worries is that this arrangement is probably a lot stronger than the drum itself and capable of breaking the studs or drum long before the puller fails.

I only know my ’35’s dimensions, other models likely have different wheel studs and dimensions, so don’t take my little sketch verbatim.

Jim

When I put the Packard (in the background) body back on 30 years ago it was a club event.

PS, Newcomen and Watt started the industrial revolution using English units, you drive on the wrong side of the road, and WWII was won by SAE and Whitworth threads against the evil metric system. Aren’t you a little ashamed to use those silly Frog units?

Jim

My four post lift is free-standing and with no special concrete reinforcement and no problem to date. Until I re-started my Pierce restoration it usually had one of my two 4500 lb Chryslers sitting on it 6ft up. The BYB is not attached to the floor, it would cause problems if it was. It just plugs into a 115V 20 amp plug with no special wiring and no problems to date. It has an option for big castors so that you can roll the complete lift with a car on it (in lowered position) to another area of the shop. I bought the option but haven’t used it so far but I might if I get another lift and it ends up being a forest of poles in my garage.

The idea for posts sunk in the concrete you can attach a winch to haul cars into the shop is something I had wished I had done. In my pics in the previous messages you can see I attached a winch to the front of the lift, but a purpose built winch attachment would have been better. Getting even a stripped down Pierce up the ramps isn’t trivial.

Jim