- Home

- About Us

- Join/Renew

- Member Benefits

- Member Pages

- Log In

- Help

- Museum Store

Either they are on a severe incline, they are traveling around the bank at Brooklands or they are a few lessons shy of being a professional photographer. You can turn them if you

1. Click on the picture to enlarge

2. Right clip and choose “save as”, then name it

#.Go to where you saved it and open it. You should be able to rotate it with most photo software

In the steel industry, there used to be people who went around and spark tested (with a grinder) large semi finished pieces of steel, specifically ingots, slabs, blooms and billets. Since all carbon steel basically looks the same, spark testing was a rough means of identifying the grade.

Below is how to read the Sparks.

Getting back to the 5/8″ X 24 threads, discussions I had with others kind of lead us to believe that they used such a fine thread due to the lack of strength in the pot mental. Reassemble is the reverse but you may have to fashion a thin washer to put between the escutcheon and the retaining nut to give a better contact surface.

In the picture above the handle has both the original threads and the new threaded nipple which will take the place of the original threads once they are cutoff.

Nipple and nut are below

Next, I hacked the pot metal with the damaged threads off at the point the threads ended. (see arrow in pic) I sawed parallel to the flats on the shaft and stopped when I hit the steel. Do it on all side then the corners. I used a chisel to split it off the shaft.

Then push the new nipple over the shaft until it bottoms on the handle and glue it in place with Liquid Steel or some other steel or aluminum filled 2 part epoxy. I would not recommend trying to solder, weld or braze the sleeve on. I guess you can drill and pin it or use your imagination how to keep it in place.

While the shaft is 5/16″ (.313 along the flats) it is .410″” diagonally. I went to ACE and in the lamp parts drawer were several threaded nipples and nuts that had a .360″” ID. The one on the left has a flange and ID thread and the one on the right has a smooth bore and OD Threads.

I used a 5/16″” triangular file and filed flats in the ID of the tubes 90 degrees apart. In the end you have a square ID hole. This was a trial and error process sneaking up to the pint it would fit over the shaft.”

Here is an assembled handle on the right and a disassembled one on the left. If you think you can save the threads and want to retap, they are 5/8″ X 24 TPI. My nephew is a gunsmith and that just happens to be a common thread in gunsmithing.

Parts identification on the handle on the left, from inside out, is Handle proper with a 5/16″ square shaft, escutcheon cover plate, escutcheon inner plate (later cars have these two parts cast together) and tubular locking nut.

Check the Pierce Arrow Library, on the left of the website. There is a copy there.

I think the steel inserts are called Invar struts. Egge won’t use that term (I think Chrysler owns the name), but when I asked someone there said that they had them. I would call and ask.

Benjamin,

Thank you for taking the time to get and post the photos. Great car

Bill

Interesting,

I see that the club has at least one car in Hawaii.

What is with the term “DEALERT”” in Motor Cars”

Jerry,

My “Motors” manual says it is positive earth (ground). There was a thread on “Turnpike Cruiser, that covered the piston options. Put Turnpike cruiser in the search field.

Bill

Down to $10,000 or best offer.

WOW. The raw aluminum and brass really look impressive. It is almost a shame to paint the aluminum

James,

Really impressive work. I am kind of partial to the ash work. Did you bend your part or cut it out of a thick board?

Bill

Here is clearer shot. You would take material from the top to shorten.

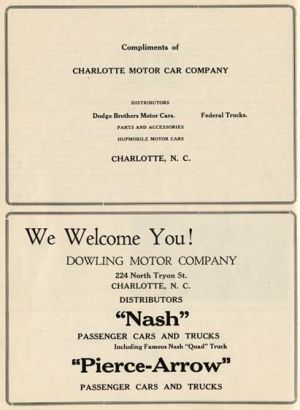

Brooks,

Here is another ad for Dowling.

Bill

Stuart, Ed and John.

Thanks for the input. Unfortunately, if you scroll all the way to the bottom it says

*** THIS CAR IS PHYSICALLY LOCATED IN LYON, ILLINOIS ***

I can’t find a Lyon, Il but Lyons is just across I55 from Midway in Chicagoland.

Since it is a closed system (with the cap on), I would think evaporation and leaks are the only factors that would generate coolant loss and evaporation would be minimal. I have never seen a value for “Normal”” coolant loss.

Is there any water in the oil or does the level rise when you check the dipstick?”

I have a link to a chart for analysis of exhaust smoke.

Good luck

What color, if any is the exhaust smoke? White could indicate coolant burning(steam).